You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question about coal

- Thread starter Wendyj

- Start date

I doubt your calipers are out of spec, but to find out, just take the longer bullet and lock the calipers in place and see if your shorter ones are coming up short with I locked(the little screw in the side). likely you have your bullet going too far into the die and the seater out too far. that would make your die "bottom out" or "crimp" before it seats the bullet consistently. try backing out the main body of the die, and moving the seater(the screw in part on top) deeper to adjust your OAL.

sorry I am having a hard time articulating this. someone will come along shortly and explain it better, hopefully with pictures. I am not in a place with reloading equip at the moment

sorry I am having a hard time articulating this. someone will come along shortly and explain it better, hopefully with pictures. I am not in a place with reloading equip at the moment

Colorado Redneck

New member

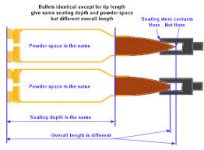

Doubt seriously it is your calipers. The bullet seater uses the ogive on bullets as the contact point. If the tip of the bullet was used as the contact point when seating, that might result in misshapen bullet tips. Since the manufacture process is not perfect most bullets will result in variance of a couple thousandths or so. Not to worry.

Attachments

Been doing some loading tonight and trying to seat 165 grain 308 at oal of 2.570.

Typo, or are you really seating that short?

2.570. It's was consistent. Second was 2.571 and last one was 2.5695.

That's a difference of .0015. Just to compare a Human hair averages .008 inches. .0015 is nothing, I mean literally nothing.

JeepHammer

Moderator

Wear on handle pivot bolts, movement of die in press threads can cause 0.001" +/- variations pretty easily.

I have to watch my seating die, the protective film that comes on some of these varmint bullets builds up and I start getting the bullet seated 0.001" or 0.002" deeper,

Clean the seater and they go right back to where I set the seater in the first place...

I've heard coated bullets build up the coating on seaters at a pretty fast rate, and those guys could care less,

Clean it when they are done...

I'm a stickler for COAL since I close up freebore by seating long and I crimp the bullet into place,

And I wouldn't worry about a thousandth or two,

In fact, I'd be happy with my press if there wasn't more slop than that in the frame to tool head...

Tool heads move, fact of life...

I have to watch my seating die, the protective film that comes on some of these varmint bullets builds up and I start getting the bullet seated 0.001" or 0.002" deeper,

Clean the seater and they go right back to where I set the seater in the first place...

I've heard coated bullets build up the coating on seaters at a pretty fast rate, and those guys could care less,

Clean it when they are done...

I'm a stickler for COAL since I close up freebore by seating long and I crimp the bullet into place,

And I wouldn't worry about a thousandth or two,

In fact, I'd be happy with my press if there wasn't more slop than that in the frame to tool head...

Tool heads move, fact of life...

Sorry about misinforming you. The oal length and numbers were 2.750 I was loading to. Not 2.570. That number come from Hodgdon website. I think I found my problem though. Was using Lee trimmer in a drill and checked first 2 and they were 2.005 on the money. Had about thirty more I had trimmed and they were all varying from 2.008 to 2.0095 and a few being 2.010.5. Tried trimming more but it won't trim any farther down. So I'm assuming if my first fired brass isn't going to trim to specs of a few thousands then my bullets will never seat to same oal.

Probably user error more than press. Using lock bushings and getting one oal perfect just figured they would all be the same. Do I need to back up seating depth stem on ever load and keep reseating until perfect or is the few thousands going to be precise. I'm heading to firing range in an hour or so and try to get some groups from all three powder loads. Guess I will see if anything is close.

You're missing the point.

OAL isn't a factor. We use it just as a simple reference to set the die to put the bullet in more or less the same depth as it was last time. Set the die, and pull the handle on the press. The die pushes on the ogive which matters and not the point of the bullet.

The point of the bullet is probably the most variable part of the bullet and is pretty useless as a reference for measurements.

OAL isn't a factor. We use it just as a simple reference to set the die to put the bullet in more or less the same depth as it was last time. Set the die, and pull the handle on the press. The die pushes on the ogive which matters and not the point of the bullet.

The point of the bullet is probably the most variable part of the bullet and is pretty useless as a reference for measurements.

A few thousandths spread is not a problem. Read post #4.

The distance the bullet jumps to the rifling with a given COAL will get longer as the throat erodes away. With a .308 Win, the throat erodes about .001" for every 20 or so shots fired. So the bullet jump distance increases that much for every 20 or so shots fired with all rounds having the same COAL. It varies a little with the powder type and charge weight.

But accuracy degrades hardly any at all. I've shot the same load with the same COAL for about 3000 rounds and bullet jump distance increased about .100". Yet accuracy through 300 yards was still 2/3 MOA at worst.

The distance the bullet jumps to the rifling with a given COAL will get longer as the throat erodes away. With a .308 Win, the throat erodes about .001" for every 20 or so shots fired. So the bullet jump distance increases that much for every 20 or so shots fired with all rounds having the same COAL. It varies a little with the powder type and charge weight.

But accuracy degrades hardly any at all. I've shot the same load with the same COAL for about 3000 rounds and bullet jump distance increased about .100". Yet accuracy through 300 yards was still 2/3 MOA at worst.

Last edited:

Well, I got to the range today and used the factory Nosler 165 bt to get zeroed on paper. Group was appr. 1 inch Tried 3 different reloads as follows. Unfortunately range is only 75 yards.

Using benchmark powder and Nosler 165 gr Ballistic tips. Once fired Hornady brass from my old rifle and Winchester primers. 5 shot groups all but one.

38.5 gr powder .8 group

40 gr .65 group

40.5 . .692. would have had the same .65 but had one fly away which took that out. Also this was only a four shot group as had one failure to fire.

I have to say the reloads at worst case were better than the factory groups. May could have done better without the shakes I had taking medication to get over this bronchitis infection. Also don't like the Nikon prostaff 7 with milldot reticle. Reticle is too thick to put on small dot in center of paper targets. Would be ok for hunting but hard for precision. Thinking of upping to a 180 grain. Since I'm 1-10 twist Brownells suggest heavier round. What do you think? Also not sure what caused failure to fire. Winchester primer seemed seated good. Can't find federal primers. Do any of you all prefer CCI primers instead. I'm still on learning curve so forgive me if I'm rambling. Good bunch of folks here and you have all been more than helpful for a new reloader. I have to say I am hooked.

Using benchmark powder and Nosler 165 gr Ballistic tips. Once fired Hornady brass from my old rifle and Winchester primers. 5 shot groups all but one.

38.5 gr powder .8 group

40 gr .65 group

40.5 . .692. would have had the same .65 but had one fly away which took that out. Also this was only a four shot group as had one failure to fire.

I have to say the reloads at worst case were better than the factory groups. May could have done better without the shakes I had taking medication to get over this bronchitis infection. Also don't like the Nikon prostaff 7 with milldot reticle. Reticle is too thick to put on small dot in center of paper targets. Would be ok for hunting but hard for precision. Thinking of upping to a 180 grain. Since I'm 1-10 twist Brownells suggest heavier round. What do you think? Also not sure what caused failure to fire. Winchester primer seemed seated good. Can't find federal primers. Do any of you all prefer CCI primers instead. I'm still on learning curve so forgive me if I'm rambling. Good bunch of folks here and you have all been more than helpful for a new reloader. I have to say I am hooked.

You're doin' great.

1:12 twists were first used for the .308 in Winchester rifles as well as M14 service rifles shooting the same round. That's good for 125 to 200 grain hunting loads. Why Remington and others use 1:10 twist is beyond me. It may be due to old timers 1:10 twist .30-06 barrels thinking a 1:12 was too slow for bullets leaving 100 fps slower from .308 cases. And Remington may well wanted to capitalize on it. A 1:10 twist is best used for 180 to 220 grain bullets in .308's.

1:12 twists were first used for the .308 in Winchester rifles as well as M14 service rifles shooting the same round. That's good for 125 to 200 grain hunting loads. Why Remington and others use 1:10 twist is beyond me. It may be due to old timers 1:10 twist .30-06 barrels thinking a 1:12 was too slow for bullets leaving 100 fps slower from .308 cases. And Remington may well wanted to capitalize on it. A 1:10 twist is best used for 180 to 220 grain bullets in .308's.

WendyJ,

Folks who play with seating depth as a tuning factor, as this note from Berger describes, typically figure they have to move a bullet at least 0.020" to as much as 0.040" to see any difference on paper, and your variation is nowhere near that.

Bart and I and others have measured bullet length variation and bullet base to ogive contact point variation, and even match bullets can vary several thousandths in those dimensions. I once measured 30 155 grain Sierra MatchKing #2155 bullets and got an extreme base to tip length spread of 0.015", with a standard deviation of 0.0035". The base to ogive measurements with Sinclair's throat diameter comparator inserts measured 0.008" in variation with 0.0025" standard deviation. There did not seem to be a correlation between base-to-tip and base-to-ogive. That is, one being on the long side didn't mean the other was. So you could expect those particular bullets to produce 0.020" variation with 0.0043" standard deviation in cartridge overall length. That length variation is probably as bad as it gets due to the way the hollow points are formed. It results in some having very uneven hollow point edges. Not enough to matter to ballistics, though; just to the calipers. They shot just fine.

P.S. Benchmark works in the .308, but is on the fast end of the burning rate range for your bullet weight. That means it will produce shorter barrel times than Varget or 4064 or the other more usual powders used with that weight. That could change your accuracy, and so would be worth experimenting with.

Folks who play with seating depth as a tuning factor, as this note from Berger describes, typically figure they have to move a bullet at least 0.020" to as much as 0.040" to see any difference on paper, and your variation is nowhere near that.

Bart and I and others have measured bullet length variation and bullet base to ogive contact point variation, and even match bullets can vary several thousandths in those dimensions. I once measured 30 155 grain Sierra MatchKing #2155 bullets and got an extreme base to tip length spread of 0.015", with a standard deviation of 0.0035". The base to ogive measurements with Sinclair's throat diameter comparator inserts measured 0.008" in variation with 0.0025" standard deviation. There did not seem to be a correlation between base-to-tip and base-to-ogive. That is, one being on the long side didn't mean the other was. So you could expect those particular bullets to produce 0.020" variation with 0.0043" standard deviation in cartridge overall length. That length variation is probably as bad as it gets due to the way the hollow points are formed. It results in some having very uneven hollow point edges. Not enough to matter to ballistics, though; just to the calipers. They shot just fine.

P.S. Benchmark works in the .308, but is on the fast end of the burning rate range for your bullet weight. That means it will produce shorter barrel times than Varget or 4064 or the other more usual powders used with that weight. That could change your accuracy, and so would be worth experimenting with.

Last edited:

JeepHammer

Moderator

The Burger information is almost identical to Sierra.

They recommend you keep freebore down to around 0.040" or under,

Unfortunately, some chambers have up to 0.250".

In the Marines, building sniper and match rounds,

The first thing we did was weigh every bullet,

Then start measuring...

The 'Average' box of 168 Match King hollow points, 100 in a box,

Half the box was under/over wight by about 1/2 grain,

Then we started throwing the proper weight bullets (+/- 1/10 grain) into the calipers for length/diameter.

Seating dies didn't just push the bullet in to COAL,

But the actual bore minimum diameter, what was the actual part of the bullet that would contact the barrel throat first.

Every sniper rifle in Marine Corps inventory has it's own seating die.

COAL was all over the place,

And you crimp the bullet into place,

So the rounds OVER COAL were tossed out.

Kind of the only way to ensure proper and consistent freebore travel...

Most match rifles have the chambers cut for a standardized round, since the Corps gun smiths can have direct access to match rifles at any time to correct chamber issues.

(You can't do that with a deployed Marine and his rifle, so you load for the specific rifle...)

-------

My beloved M14 had a 1/11-3/4 inch barrel (1/11.75")

After building them in the Corps for 14 years, I'm POSITIVE about that...

The ONLY M14s that came with 1:12 barrels were the XM14,

The M14 before it was adopted for the standard battle rifle.

DOD required 268 changes in the XM14 before it became the M14.

The first XM14s submitted for testing were chambered in .30-06, two are still at the Marine Corps Museum in Quantico, along with the next 20 or so evolutions of the XM14 before being adopted.

That's perfectly acceptable, and mostly standard for up to 168 grain bullets.

Beyond 168 grain the bullet goes transonic/destabilizes and does some flaky stuff somewhere between 600 & 1,000 yards...

That's pretty simple, beyond 147 grain bullets (IE: 150 and up), the 1/10 is perfectly acceptable up to 200 grain bullets.

Anything past 175 (178 Match Kings in particular) it takes a tighter barrel twist to stabilize correctly past 600 yards.

Inaccurate.

Again, a 180 grain large/dangerous game hunting bullet won't stabilize past 600 yards.

The 'Old Timers' knew EXACTLY what they were doing,

They actually had GUN SMITHS back then...

Younger 'Internet Experts' read CRAP from some manufacturer and *THINK* they have the inside track,

When they have no FIRST HAND KNOWLEDGE of the subject...

Close,

The 'Tactical' rounds in .308 are the reason, they are going more and more to above 168 grain bullets, that a 1/12 twist won't stabilize at range with anything bigger than about 168 grain...

Not that a 'Tactical' civilian is going to find the difference...

The 'Average' police 'Sniper' shot is 47 yards,

They rarely practice beyond 300 yards.

----

For some reason, the general public can't differentiate between a light, thin skinned game animal,

And a large, dangerous animal round.

Same with 'Target' rounds and 'Tactical' rounds...

If it comes in a black box with red stripes and says "Tactical", it sells to idiots at insane prices no matter how lousy it's going to shoot in their firearm.

The same goes for guys buying 'Premium' and 'Match' ammo, always the WRONG weight bullet for the rifling they are shooting...

Or they are shooting it in a $1,000 "Black" rifle with a $69.95 optic on $15 mounts and complaining the rifle is junk...

----

It's pretty easy, pick up a book on BALLISTICS,

Or even better, two or three...

Internal ballistics (inside the rifle),

External ballistics (from muzzle to target)

Terminal ballistics (Bullet INSIDE target)

If you are a reader, and have ANY interest in the subject,

The DOD has produced some very good NO CRAP, no product slant testing results in book form...

You might even learn a thing or two about chambers you didn't know...

They recommend you keep freebore down to around 0.040" or under,

Unfortunately, some chambers have up to 0.250".

In the Marines, building sniper and match rounds,

The first thing we did was weigh every bullet,

Then start measuring...

The 'Average' box of 168 Match King hollow points, 100 in a box,

Half the box was under/over wight by about 1/2 grain,

Then we started throwing the proper weight bullets (+/- 1/10 grain) into the calipers for length/diameter.

Seating dies didn't just push the bullet in to COAL,

But the actual bore minimum diameter, what was the actual part of the bullet that would contact the barrel throat first.

Every sniper rifle in Marine Corps inventory has it's own seating die.

COAL was all over the place,

And you crimp the bullet into place,

So the rounds OVER COAL were tossed out.

Kind of the only way to ensure proper and consistent freebore travel...

Most match rifles have the chambers cut for a standardized round, since the Corps gun smiths can have direct access to match rifles at any time to correct chamber issues.

(You can't do that with a deployed Marine and his rifle, so you load for the specific rifle...)

-------

1:12 twists were first used for the .308 in Winchester rifles as well as M14 service rifles shooting the same round.

My beloved M14 had a 1/11-3/4 inch barrel (1/11.75")

After building them in the Corps for 14 years, I'm POSITIVE about that...

The ONLY M14s that came with 1:12 barrels were the XM14,

The M14 before it was adopted for the standard battle rifle.

DOD required 268 changes in the XM14 before it became the M14.

The first XM14s submitted for testing were chambered in .30-06, two are still at the Marine Corps Museum in Quantico, along with the next 20 or so evolutions of the XM14 before being adopted.

That's good for 125 to 200 grain hunting loads.

That's perfectly acceptable, and mostly standard for up to 168 grain bullets.

Beyond 168 grain the bullet goes transonic/destabilizes and does some flaky stuff somewhere between 600 & 1,000 yards...

Why Remington and others use 1:10 twist is beyond me.

That's pretty simple, beyond 147 grain bullets (IE: 150 and up), the 1/10 is perfectly acceptable up to 200 grain bullets.

Anything past 175 (178 Match Kings in particular) it takes a tighter barrel twist to stabilize correctly past 600 yards.

It may be due to old timers 1:10 twist .30-06 barrels thinking a 1:12 was too slow for bullets leaving 100 fps slower from .308 cases.

Inaccurate.

Again, a 180 grain large/dangerous game hunting bullet won't stabilize past 600 yards.

The 'Old Timers' knew EXACTLY what they were doing,

They actually had GUN SMITHS back then...

Younger 'Internet Experts' read CRAP from some manufacturer and *THINK* they have the inside track,

When they have no FIRST HAND KNOWLEDGE of the subject...

And Remington may well wanted to capitalize on it. A 1:10 twist is best used for 180 to 220 grain bullets in .308's.

Close,

The 'Tactical' rounds in .308 are the reason, they are going more and more to above 168 grain bullets, that a 1/12 twist won't stabilize at range with anything bigger than about 168 grain...

Not that a 'Tactical' civilian is going to find the difference...

The 'Average' police 'Sniper' shot is 47 yards,

They rarely practice beyond 300 yards.

----

For some reason, the general public can't differentiate between a light, thin skinned game animal,

And a large, dangerous animal round.

Same with 'Target' rounds and 'Tactical' rounds...

If it comes in a black box with red stripes and says "Tactical", it sells to idiots at insane prices no matter how lousy it's going to shoot in their firearm.

The same goes for guys buying 'Premium' and 'Match' ammo, always the WRONG weight bullet for the rifling they are shooting...

Or they are shooting it in a $1,000 "Black" rifle with a $69.95 optic on $15 mounts and complaining the rifle is junk...

----

It's pretty easy, pick up a book on BALLISTICS,

Or even better, two or three...

Internal ballistics (inside the rifle),

External ballistics (from muzzle to target)

Terminal ballistics (Bullet INSIDE target)

If you are a reader, and have ANY interest in the subject,

The DOD has produced some very good NO CRAP, no product slant testing results in book form...

You might even learn a thing or two about chambers you didn't know...

Last edited: