I bought this Python whose cylinder collar was replaced by a steel bushing.

I learnt from dfariswheel that “what prevents the cylinder from moving forward is the fit of the small collar on the front of the cylinder contacting the frame inside the window just below the rear of the barrel”.

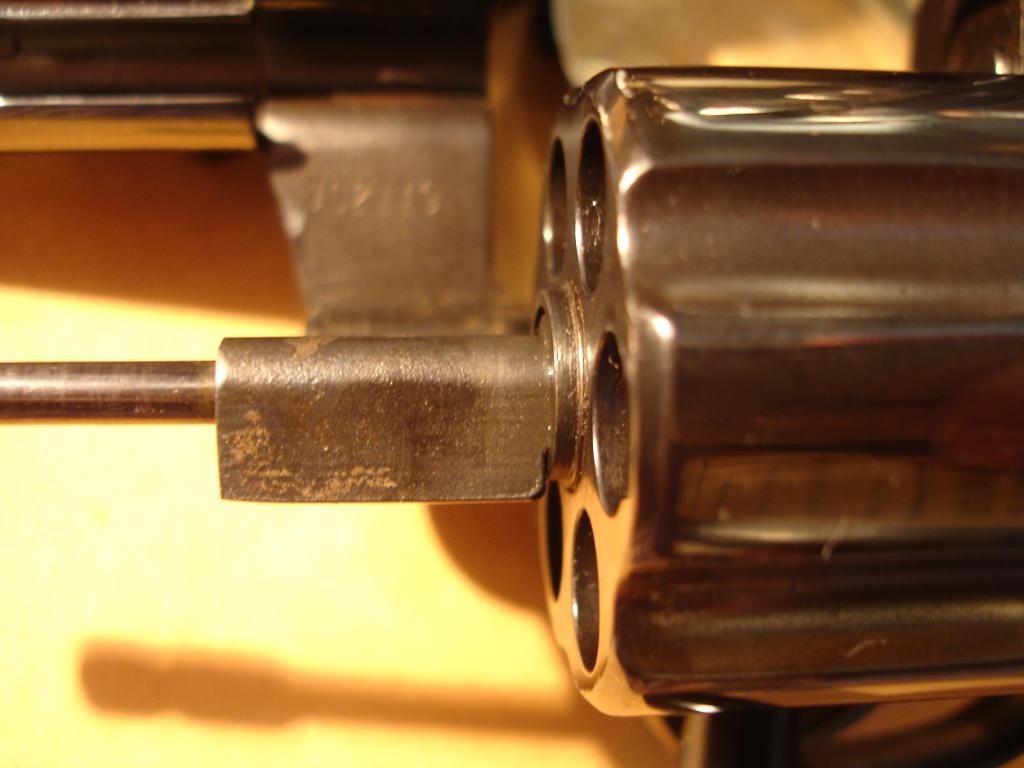

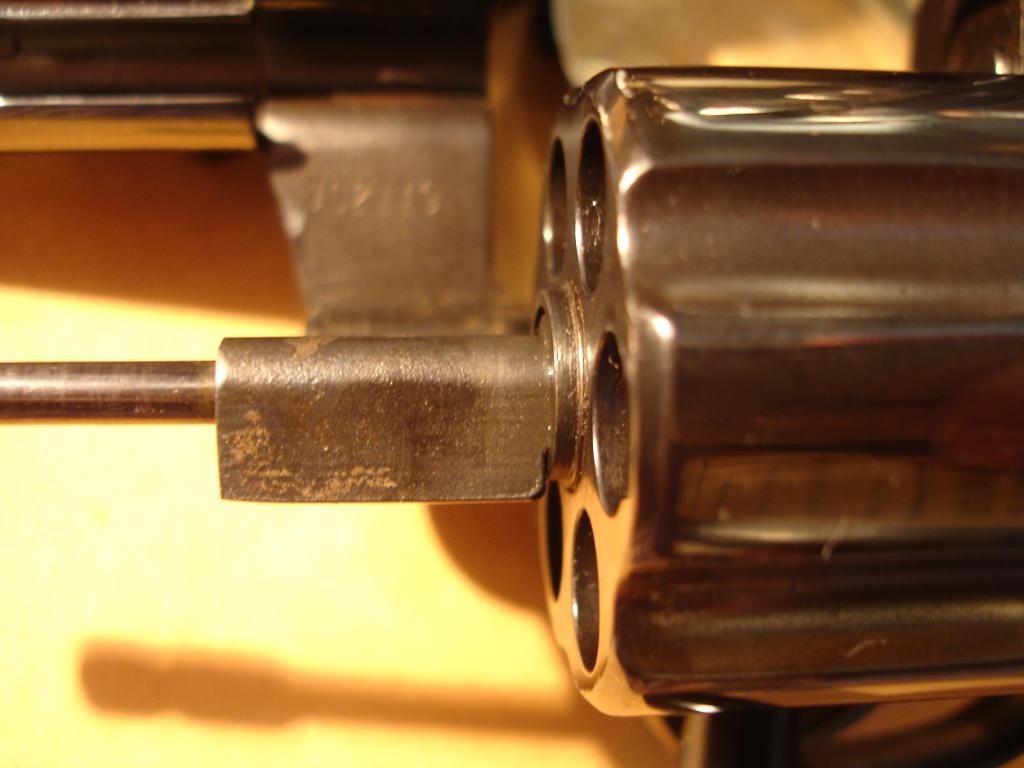

There is no excesive endshake (as far as I can see - I have not measured it) but the thing is that in my new (to me) Python the collar does not touch the frame. It is in contact with the yoke, and the yoke seems to fit the frame, but the collar does not touches the frame. Please see pics below.

Can this cause problems? Is there a solution?

Appreciate your help

collar does not contact frame

collar in contact with yoke

collar in contact with yoke (click image for video)

yoke/frame fit click image for video

I learnt from dfariswheel that “what prevents the cylinder from moving forward is the fit of the small collar on the front of the cylinder contacting the frame inside the window just below the rear of the barrel”.

There is no excesive endshake (as far as I can see - I have not measured it) but the thing is that in my new (to me) Python the collar does not touch the frame. It is in contact with the yoke, and the yoke seems to fit the frame, but the collar does not touches the frame. Please see pics below.

Can this cause problems? Is there a solution?

Appreciate your help

collar does not contact frame

collar in contact with yoke

collar in contact with yoke (click image for video)

yoke/frame fit click image for video

Last edited: