Machineguntony

New member

I just got back into long range shooting and bought a bolt action 308, a Remington 700 SPS.

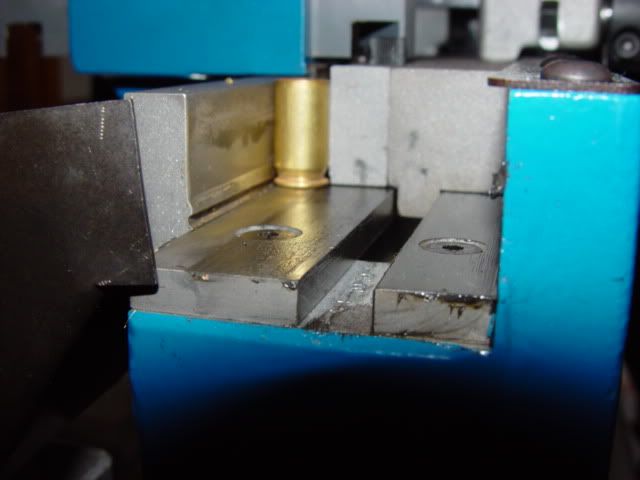

I'm having a problem with brass that was previously shot in my open bolt guns. The reloaded round (with that brass) will not chamber in my bolt action gun, no matter what I do to the brass.

When I say that the round won't chamber, I mean the the bolt handle will not go down into its closed position.

It's Lake City brass.

I've resized the brass with a regular Dillon 308 die. That didn't allow the round to chamber in the rifle.

Then I used a RCBS small base die. That didn't allow chambering of the round either.

The dimensions on the brass are all correct. I trimmed the brass. The measurements on the finished round are all correct. I also seated the bullet deeper to make sure that the bullet wasn't contacting the rifling.

The rounds chamber and fire fine in my open bolt guns, but they won't chamber in the bolt gun. I realize the open bolt guns have more generous chambers, but I thought the resizing die was supposed to resize the brass to SAAMI specs.

As a comparative test, I borrowed my friends 308 once fired brass, that he had shot out of his bolt gun. Those reloaded rounds chambered and fired fine out of my bolt gun.

Any thoughts on what's going on? Any solutions to use this brass in a bolt gun?

I'm having a problem with brass that was previously shot in my open bolt guns. The reloaded round (with that brass) will not chamber in my bolt action gun, no matter what I do to the brass.

When I say that the round won't chamber, I mean the the bolt handle will not go down into its closed position.

It's Lake City brass.

I've resized the brass with a regular Dillon 308 die. That didn't allow the round to chamber in the rifle.

Then I used a RCBS small base die. That didn't allow chambering of the round either.

The dimensions on the brass are all correct. I trimmed the brass. The measurements on the finished round are all correct. I also seated the bullet deeper to make sure that the bullet wasn't contacting the rifling.

The rounds chamber and fire fine in my open bolt guns, but they won't chamber in the bolt gun. I realize the open bolt guns have more generous chambers, but I thought the resizing die was supposed to resize the brass to SAAMI specs.

As a comparative test, I borrowed my friends 308 once fired brass, that he had shot out of his bolt gun. Those reloaded rounds chambered and fired fine out of my bolt gun.

Any thoughts on what's going on? Any solutions to use this brass in a bolt gun?