Rangerrich99

New member

So here's my problem:

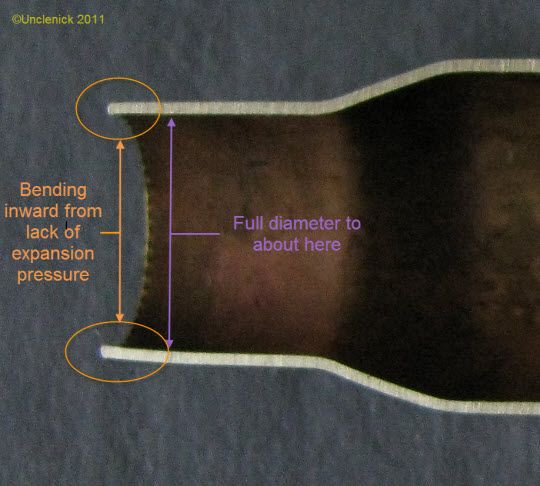

The other day I was preparing to trim some .223 rem brass on my Hornady camlock case trimmer and several case mouths wouldn't fit over the pilot, making it impossible for the case mouths to make contact with the cutter blade. In fact, the case mouths are so tight they get stuck about a quarter inch from the cutter.

These are mostly federal (FC) brass and they all have been reloaded at least 6-7 times. All brass had been deprimed and full-length resized (6-7 times), and most had been trimmed previously at least twice without issue. I checked twice that I had the correct pilot installed, so that's not the problem. Also, I have other FC brass that I've reloaded at least ten times and haven't had this issue.

I know brass isn't expensive and I've got a couple thousand pieces so this is not a critical issue, I was just curious if this is normal and why exactly this happened.

Is this phenomenon related to how brass flows during the firing event? Or is there something else going on?

The other day I was preparing to trim some .223 rem brass on my Hornady camlock case trimmer and several case mouths wouldn't fit over the pilot, making it impossible for the case mouths to make contact with the cutter blade. In fact, the case mouths are so tight they get stuck about a quarter inch from the cutter.

These are mostly federal (FC) brass and they all have been reloaded at least 6-7 times. All brass had been deprimed and full-length resized (6-7 times), and most had been trimmed previously at least twice without issue. I checked twice that I had the correct pilot installed, so that's not the problem. Also, I have other FC brass that I've reloaded at least ten times and haven't had this issue.

I know brass isn't expensive and I've got a couple thousand pieces so this is not a critical issue, I was just curious if this is normal and why exactly this happened.

Is this phenomenon related to how brass flows during the firing event? Or is there something else going on?