I'm new to handloading and I recently had a problem with my first batch of .223 handloads and I'm hoping someone can help explain what occurred.

I loaded a test batch of 10 rounds, all identical, first two fired fine in my AR 15, third round did not fire, when I tried to eject the round i couldn't extract it with the charging handle, I had to take the rifle home and use a rod with a block of wood to extract the bullet. It was clear in looking at the round that the primer was never struck by the firing pin.

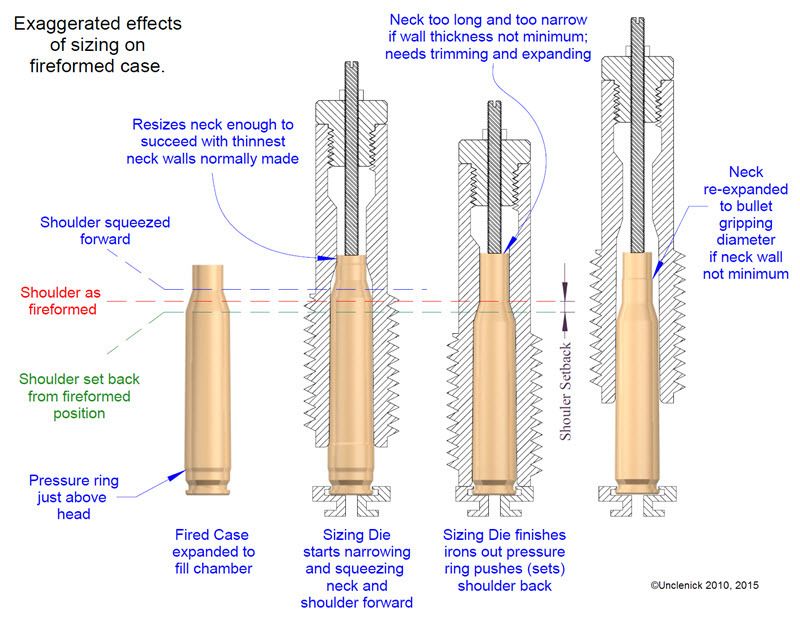

So I'm pretty sure I have a headspace problem and that is why the primer was not struck, I checked some previously fired cartridges with my wilson case gauge and it looks like my chamber is .005 larger than SAAMI specs and I resized my brass pretty close to the minimum on the case gauge.

The thing that baffles me is, why couldn't I extract the round with the charging handle? I feel like I'm missing something, like I didn't have enough taper crimp and when I released the bolt to chamber the round the bullet pushed back into the case wedging it in the chamber, if this was the case it is probably a very good thing the firing pin didn't strike the primer.

Any help would be greatly appreciated.

Here is some additional data.

My brass was all once fired Federal Cartridge, that I fired previously.

I cleaned brass with steel pin tumbler

I used the bootleg case lube mix - lanolin and ipa

I'm using Dillon carbide dies on RL 550b

I used wilson case gauge when adjusting resizing and sized to minimum

None of my resized cases were over 1.750

I trimmed the 10 rounds after resizing to be identical at 1.740

I ran the brass over crimp removal tool and primer pocket cleaner tool with my lyman case prep

I used CCI small rifle primers

Bullet - sierra mk 69g hbt

Powder - Varget 25.3g

Overall Case Length 2.260

Set the taper crimp to be .002

I loaded a test batch of 10 rounds, all identical, first two fired fine in my AR 15, third round did not fire, when I tried to eject the round i couldn't extract it with the charging handle, I had to take the rifle home and use a rod with a block of wood to extract the bullet. It was clear in looking at the round that the primer was never struck by the firing pin.

So I'm pretty sure I have a headspace problem and that is why the primer was not struck, I checked some previously fired cartridges with my wilson case gauge and it looks like my chamber is .005 larger than SAAMI specs and I resized my brass pretty close to the minimum on the case gauge.

The thing that baffles me is, why couldn't I extract the round with the charging handle? I feel like I'm missing something, like I didn't have enough taper crimp and when I released the bolt to chamber the round the bullet pushed back into the case wedging it in the chamber, if this was the case it is probably a very good thing the firing pin didn't strike the primer.

Any help would be greatly appreciated.

Here is some additional data.

My brass was all once fired Federal Cartridge, that I fired previously.

I cleaned brass with steel pin tumbler

I used the bootleg case lube mix - lanolin and ipa

I'm using Dillon carbide dies on RL 550b

I used wilson case gauge when adjusting resizing and sized to minimum

None of my resized cases were over 1.750

I trimmed the 10 rounds after resizing to be identical at 1.740

I ran the brass over crimp removal tool and primer pocket cleaner tool with my lyman case prep

I used CCI small rifle primers

Bullet - sierra mk 69g hbt

Powder - Varget 25.3g

Overall Case Length 2.260

Set the taper crimp to be .002