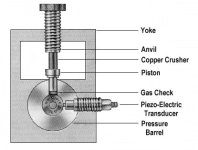

The European style channel transducers are used under CIP standards to measure pressure in the case by drilling holes in them at locations specified in the CIP homologation drawings. NATO in Europe has its own test standard, EPVAT testing, that uses the same kind of channel transducer to measure pressure through a hole drilled in the chamber just after the case mouth. The conformal pressure transducers used in this country have a hole into the chamber, but there is a piston shaped to conform to the chamber that drives the piezoelectric material to measure pressure over to of the case brass, which is not drilled, so there is no direct gas pressure.

ShootistPRS said:

SAAMI switched to the piezoelectric method because it showed the pressure time curve with more detail.

That is the statement I was correcting. SAAMI procedures make no mention of pressure curves. They only call for peak readings. See pages 178 and 179 (190 and 191 in Acrobat's page counter) of their

2015 Rifle Standard. The folks you mention are going beyond what the SAAMI standard calls for in order to collect even more information, which is great, but SAAMI doesn't get the credit for it.

ShootistPRS said:

The piezoelectric method is easily calibrated where the application of the resistive measurement system can vary wildly from improper application of the device.

While it does take a little care to install the gauge, you can calibrate the "load cell" exactly the same ways most pressure transducer owners commonly calibrate theirs. SAAMI has a designated manufacturer for each commercial chambering, who is charged with providing both proof and reference loads to the industry. Reference loads are a lot of loads within the normal pressure range for the cartridge, but whose actual peak pressure is measured by multiple laboratories belonging to SAAMI members, and the average result is taken and decalred to be the actual pressure value for the lot. It is sent back around to the same labs every two years to update the pressure value as the lot ages and bullet pull grows with case-to-bullet cold bonding. The buyer of a new transducer barrel can calibrate it by firing reference ammunition and adjusting its transducer charge factor so the mean reading matches the reference ammunition declared value, enabling him to produce ammunition matching the industry standard. You can fire reference loads in a gun with strain gauges afixed as well, and adjust the gauge factor to give the same matching result. There is no more or less, nor even any differnt work involved.

Without reference loads, SAAMI has a hydraulic pressure fixture it uses to statically calibrate a transducer. This is analogous to copper slug makers performing static calibration of slugs for copper crushers with stacks of weights. This is what the reference load ammunition testing labs do before measuring their samples of a reference lot. Again, the same may be done with a gun with a strain gauge attached. Harold Vaughn demonstrated this in his book, Rifle Accuracy Facts (P12 & 13). He bored out the head of a case and threaded it and through it fixed the neck with a threaded steel insert that stops against the shoulder, so he now has threads at the head and the neck. He used Loctite to secure them. He used Teflon tape with threads on a head plug that screwed in and on 1/4" hydraulic line threaded into the case mouth insert. The line extended out of the muzzle, where it met an hydraulic cylinder equipped with a calibrated 15 kpsi gauge. He got the case, tubing and cylinder filled with hydraulic fluid and pumped it up to 15,000 psi. He noted the case conformed to the chamber at about 12,000 psi, and after that he had linear readings. All, no more or less trouble than building a SAAMI hydraulic calibration jig and no more or less accurate in the end.

Absent hydraulic gear or reference loads, the calculated method of scaling by application of the Lame theorem-based hoop stress forumulas to the chamber is not too bad. The gauge I have on an old '03 barrel tells me some old M2 Ball I have is producing 49,000 psi based on the Pressure Trace's software that makes the calculations for you. Knowing the powder used and having measured the velocity from that particular barrel, and duplicating it both based on powder company results (for H380; the canister grade of the WC852 actuallin in these cartridges) and QuickLOAD, it's seems pretty close to the 5% precision that Dr. Oehler considers the general limit of reliability of commercial absolute pressure numbers to be. When you consider that SAAMI allows individual rounds within a 10 round average right at the Maximum Average Pressure (MAP) number to be as much as 18% above MAP, 5% error is not a hazard, not even with the further shot-to-shot variation that is typical. More important to me, it does the important job of creating a basis for comparison when switching powders and the like.

The SAAMI hydraulic method of calibration is described on pages 167-175 (179- 187 in Acrobat) of the document I already linked to, above. Its accuracy seems to be in the same ballpark. In the example below, it seems to have produced about ±5.5% error among labs measuring the same lot of reference ammunition.

ShootistPRS said:

If it is installed properly it provides nearly the same level of accuracy as the piezoelectric system.

Or better, in terms of consistency, if Denton Bramwell's assessment is correct. They won't have the durability, though, so you'd have to budget some reference loads if you want to produce a lot of different loads meeting the industry pressure standard.

ShootestPRS said:

Other times and most often powders that had been considered good for a case had to be dropped because they were slow enough to cause the secondary pressure peak that was considerably higher than the first pressure spike.

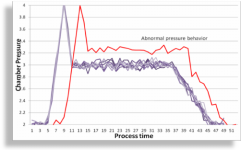

This is the single most interesting comment you made if you were referring to fellows looking at transducer curves. Here's a Pressure Trace plot of Winchester brand 223 ammunition:

Note the extreme secondary pressure spike, capable of ringing barrels. The pressure event happens down the bore, and not instantly in the chamber, but the reflected wave down the barrel steel stretches the strain gauge to give that result. I would not expect to see it on a pressure transducer because it moves with the steel. Indeed, even if Winchester used a peak reading gauge or a copper crusher, that much actual pressure at the breech would show up as an overpressure spike. Charlie Sisk reported demonstrating blowing muzzles off rifles with those spikes to industry folk, whom he said just shrugged it off because their gear didn't show a problem. It would take himten or twelve rounds of the worst offending load he had for the 338 to do this, but it would blow them, despite looking good on a transducer.

So I am not clear what the folks you mentioned are seeing. Your illustration of an output showed a delayed firing pretty clearly, but I would like to know if any trace of the above type secondary spikes have shown up on that newer equipment. The peak should be the peak, regardless of what point it occurs at during barrel time, so the old Winchester gear should have revealed it if it was more than a wave in the barrel.