I've returned from the range after shooting my first batch of reloaded 9 mm. As I went to decap and size the brass, I noticed what I'm pretty sure are what I've seen described as "flowing primers," a fairly late pressure sign. Sadly, my range brass isn't very well sorted -- it's a topic for a different forum, I guess, as to how to corral one's own flying brass at a public range -- so I can't group them strictly by load, but I can at least tell which powder was used. Load data for this first batch came straight off the instructions that came with the Lee carbide die set for 9 mm. All shots were fired out of a Beretta 92S, one of these surplus Italian police sidearms, which appears to be in very good condition and shows no sign of misuse or having fired tens of thousands of rounds. All brass was bought as range brass, so I don't know how many loads they've seen. All rounds were topped by 125 gr Missouri Bullet Co. semi-wadcutters, HiTek coated. They're listed as.356 and Brinell hardness 18, if that matters.

Speer nickel-plated, mix of regular and +P brass

CCI 500 small pistol primers

15 each of 3.8 gr, 4.0 gr, and 4.2 gr Universal

Lee Factory Crimp Die about 3/4 turn past contact

COAL ~1.124"

Winchester nickel-plated brass (might have also been a mix of regular and +P)

CCI 550 magnum small pistol primers

15 each of 3.8 gr. 4.0 gr, and 4.2 gr Titegroup

Taper crimp applied with Lee bullet seating die only

COAL ~1.118"

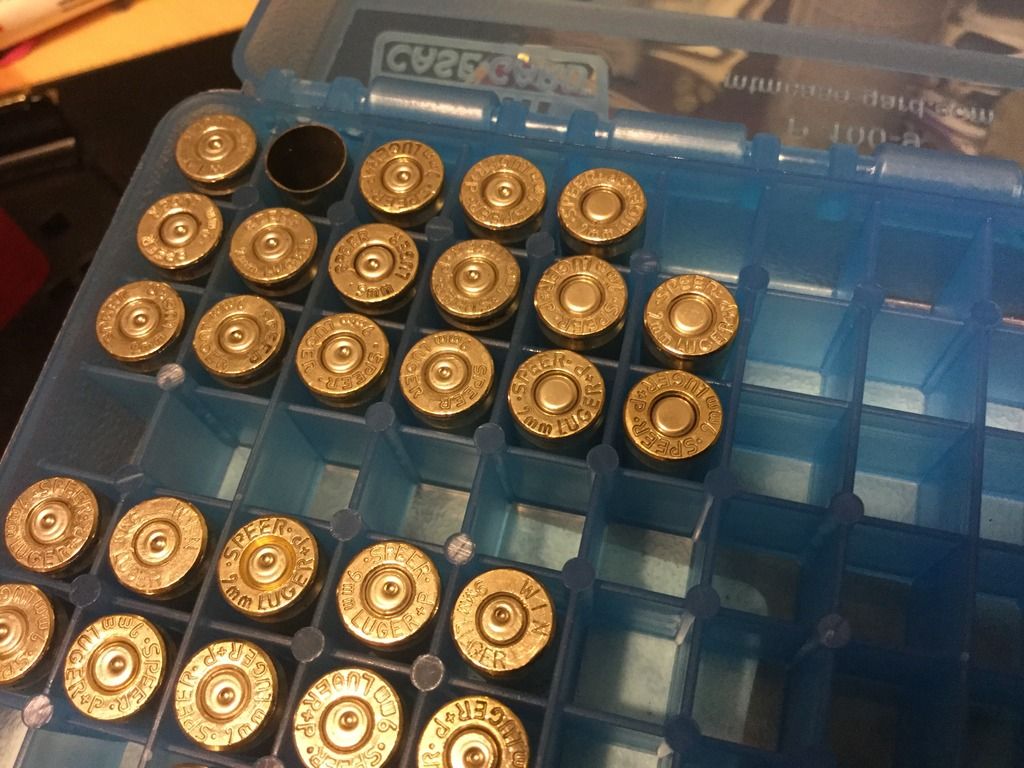

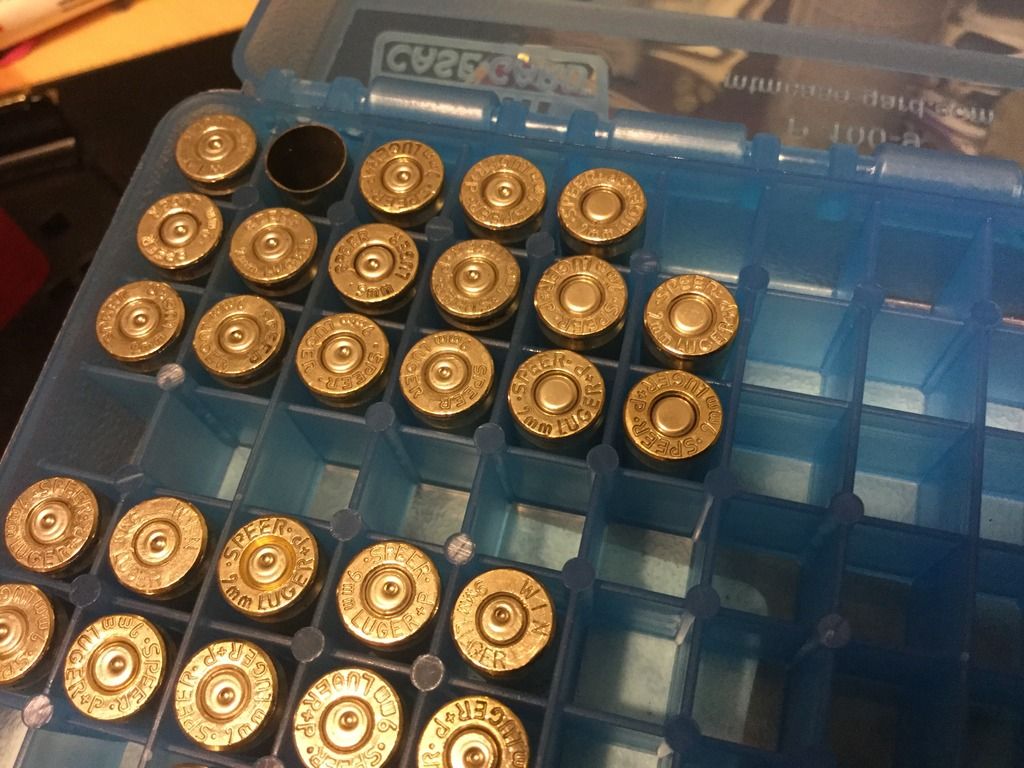

As I hope you can see in these pics (with a few unstruck primed cases for comparison), all of them seem to have the "flowing primers" to some extent. As a group, I couldn't tell a big difference between the Universal/LPP and the Titegroup/MagnumLPP rounds.

Thoughts?

Randy...

Speer nickel-plated, mix of regular and +P brass

CCI 500 small pistol primers

15 each of 3.8 gr, 4.0 gr, and 4.2 gr Universal

Lee Factory Crimp Die about 3/4 turn past contact

COAL ~1.124"

Winchester nickel-plated brass (might have also been a mix of regular and +P)

CCI 550 magnum small pistol primers

15 each of 3.8 gr. 4.0 gr, and 4.2 gr Titegroup

Taper crimp applied with Lee bullet seating die only

COAL ~1.118"

As I hope you can see in these pics (with a few unstruck primed cases for comparison), all of them seem to have the "flowing primers" to some extent. As a group, I couldn't tell a big difference between the Universal/LPP and the Titegroup/MagnumLPP rounds.

Thoughts?

Randy...

Last edited: