William,

That is some butt-ugly pitting. Did you remove the original corrosion that caused it? The only ways to remove pitting that I am aware of are to re-contour the barrel to cut through the pitting, or fill the pits with welding, then restore the original contour, or build up a very heavy hard chrome plate, then re-contour to original specs with a toolpost grinder. The first option leaves the barrel lighter and may compromise its accuracy if the added “whippiness” doesn’t vibrate agreeably. The second option is used by restorers, and is slow and labor intensive and may ruin accuracy by imposing axi-asymmetric stresses where the welding is applied. The last method is least likely to affect accuracy adversely, but you will have to want a hard chrome finish and it won’t match the original.

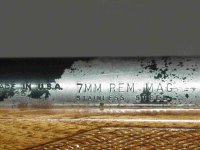

The original finish looks chipped to me. Bluing usually either blends as it wears, fading out as you go away from the wear point, or it is gone only where corrosion has hit, but remains between the pits. The chips tell me this was some kind of painted finish applied to get around the fact they didn’t have a good bluing formula for stainless at the time (they exist now); probably a baking lacquer, like Brownells’ Aluma-Hyde (sp?). If you can find out exactly what it was, you can probably get it re-done to near-original appearance.

I am going to guess this gun was “cared for” with a hygroscopic oil of some kind (saddle soap, for example) that someone thought would be good for it. The moisture was gradually absorbed by the lacquer, causing it to hold the moisture against the steel before ultimately flaking off the next time someone rubbed against it. The stainless steel had never been passivated, and indeed may actually have been pickled to remove surface chromium oxide and to activate it so the finish would adhere better. Thus it was vulnerable to any free iron in it rusting.

Ask Mete, but I believe the non-magnet quality only applies to the austenitic stainless (i.e., 316) used in surgical implants and the like. A tool maker told me once there was only one “True” stainless (probably referring to 316) that really wouldn’t corrode, and that it wasn’t heat-treatable or tough enough for modern gun barrel pressures; this was 35 years ago and may no longer be true, but maybe. . . In any case, your gun barrel is just a corrosion resistant stainless, like most stainless guns and tools are made from.

If the gun shoots well, I would take it to a gunsmith to remove the rest of the original finish and buff it and re-paint it to gloss over the exterior pits (or else bead blast it for a matte white finish) and ignore the pitting that the stock covers. Why go to a lot of expense to potentially ruin its accuracy? If you think it has collector value, you’re better off to sell it as-is, since any messing with the original finish will detract from its collecting value.

If you clean it up, I would also look at removing all traces of whatever-it-was from the stock before putting it all back together.

Nick