Well, unless I pull the hammer back about 2mm first.

Before I get all tedious and measuring engagement surfaces between the two parts, I got a nice postwar Walther P1 slide to put on a WWII P.38, for use as a shooter.

Barrel fits in just fine, all safety functions check out, and the FP launches a pencil just fine when dropping the hammer.

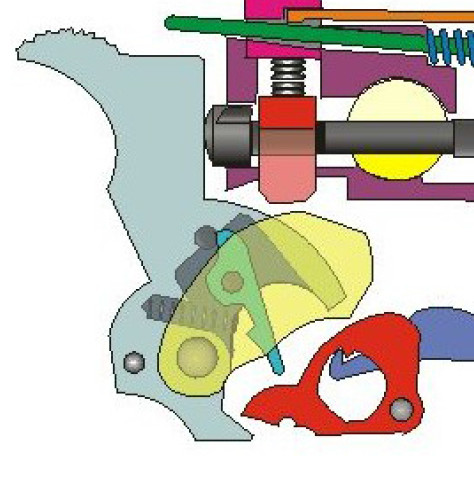

It seems to me (without further examination) that the fit of the slide for whatever reason allows the hammer to come just a bit too far forward, putting the DA notch just out of reach of the sear or trigger bar (been a while since I looked at the inner workings, but the sear was replaced years ago because of the prior owner's clumsy attempt at a trigger job). The hammer is solidly stuck and no amount of hauling on the trigger will make it budge.

But pulling back on the hammer just a bit results in a faint click and the DA works normally from there. At least it's smoother than one on an H&K VP70...

So is there an easy fix for this? I remember the sear as being a real booger to wiggle into the frame... My hope is that it's something really minor or hard to botch like stoning a bit on the hammer notch or the trigger bar.

Thanks!!!

Before I get all tedious and measuring engagement surfaces between the two parts, I got a nice postwar Walther P1 slide to put on a WWII P.38, for use as a shooter.

Barrel fits in just fine, all safety functions check out, and the FP launches a pencil just fine when dropping the hammer.

It seems to me (without further examination) that the fit of the slide for whatever reason allows the hammer to come just a bit too far forward, putting the DA notch just out of reach of the sear or trigger bar (been a while since I looked at the inner workings, but the sear was replaced years ago because of the prior owner's clumsy attempt at a trigger job). The hammer is solidly stuck and no amount of hauling on the trigger will make it budge.

But pulling back on the hammer just a bit results in a faint click and the DA works normally from there. At least it's smoother than one on an H&K VP70...

So is there an easy fix for this? I remember the sear as being a real booger to wiggle into the frame... My hope is that it's something really minor or hard to botch like stoning a bit on the hammer notch or the trigger bar.

Thanks!!!