Contacted Swede Nelson & asked for a 2 cavity NOE 454-255-RF mould. He had one & only a few days later it arrived. The man is quick.

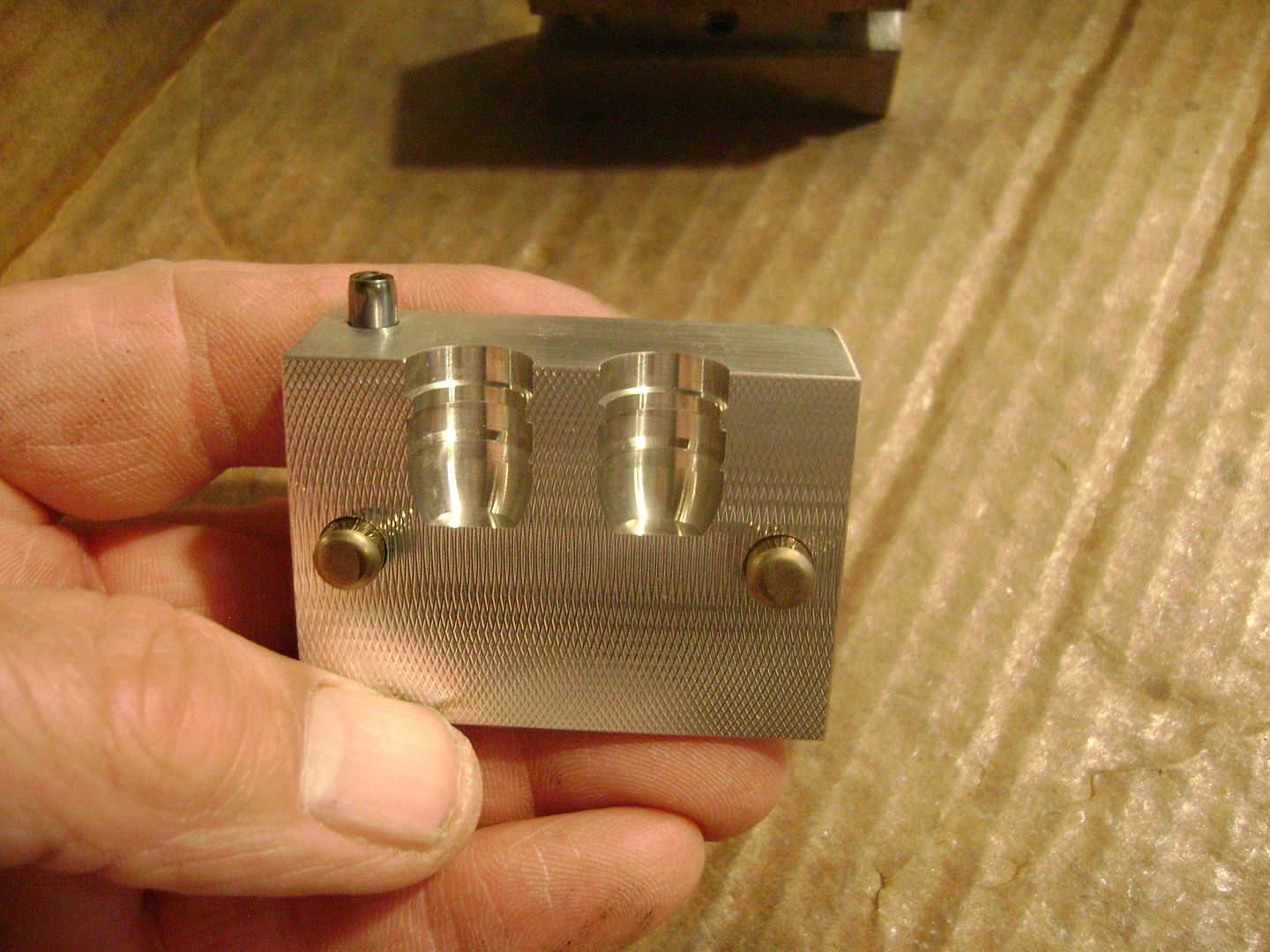

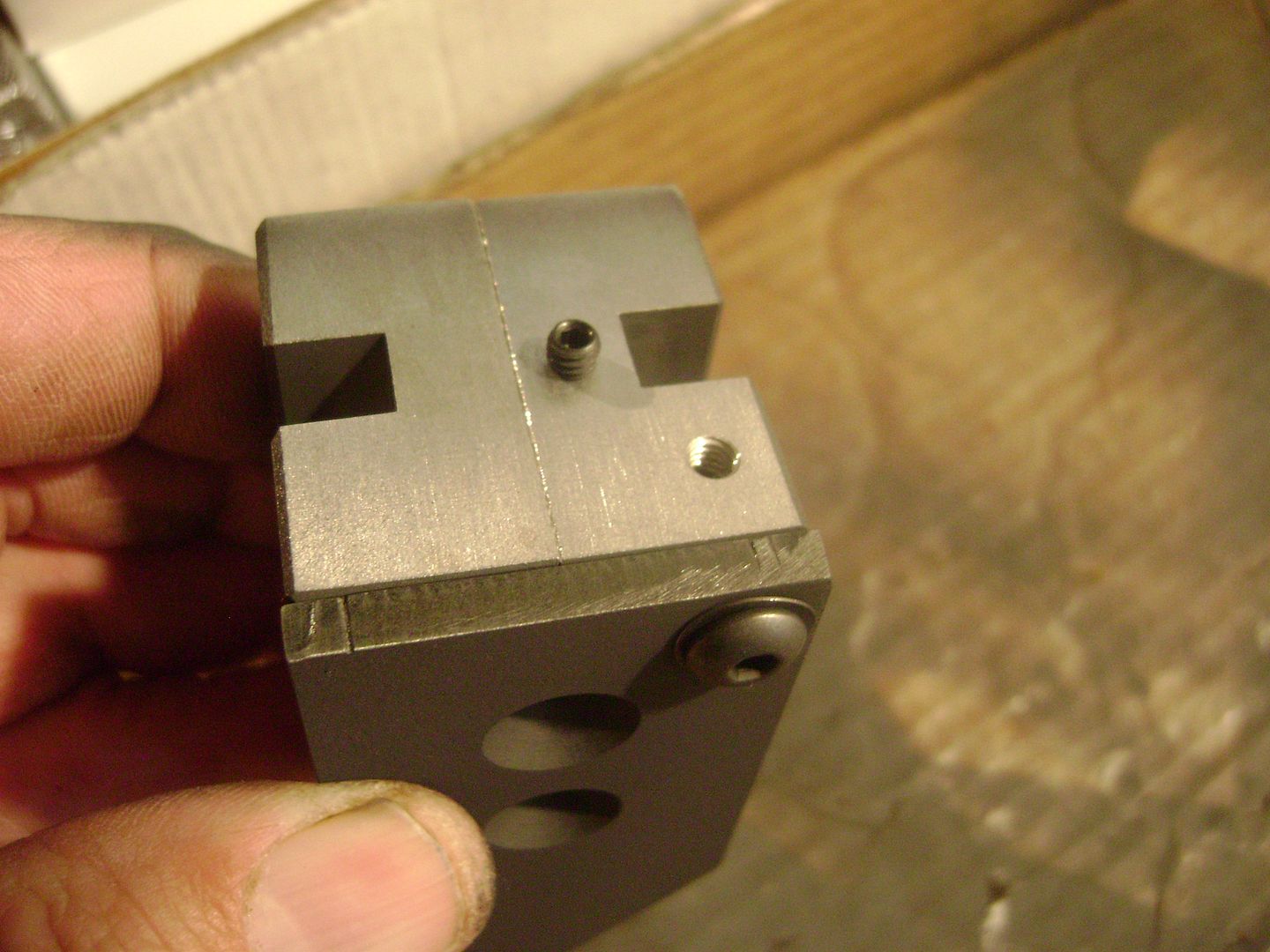

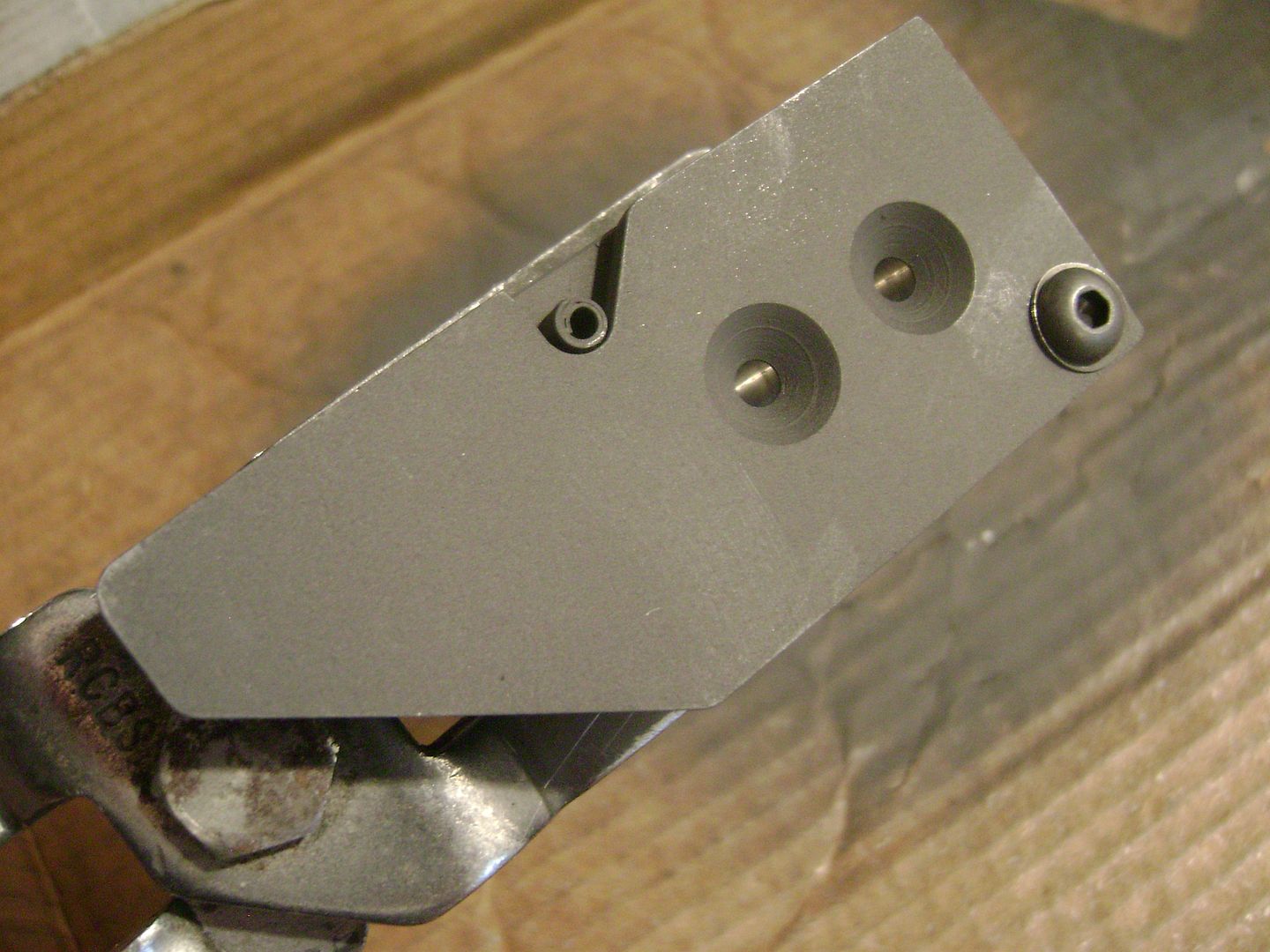

Open her up & took a look. The blocks were clean, no burrs or out of place tool marks. The cavities were beautiful. Removing the sprue plate, screw & set screw I gave the blocks a going over with a nylon brush & hot soapy water. She looked good. The sprue plate was cleaned with starting fluid & brush.

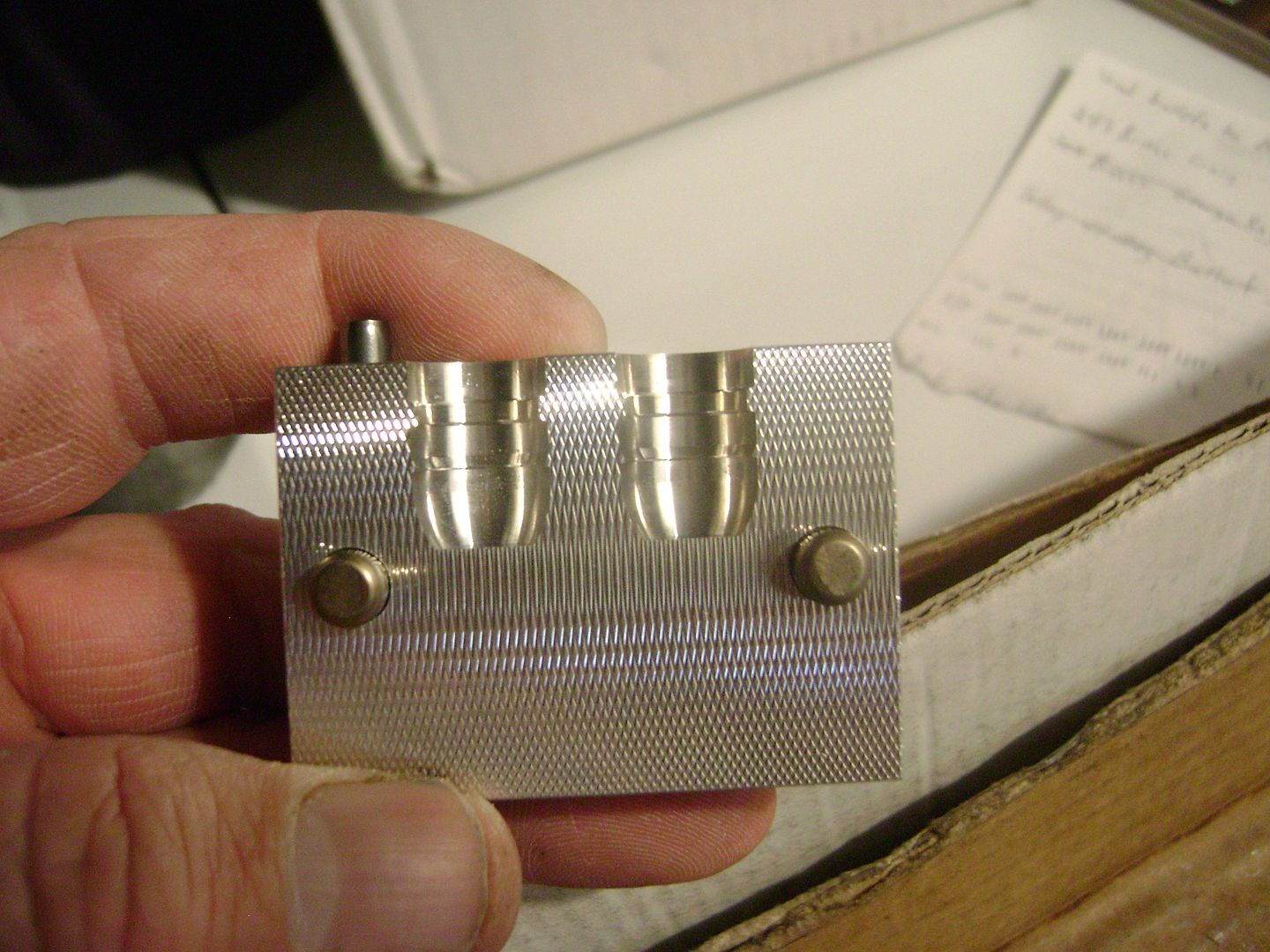

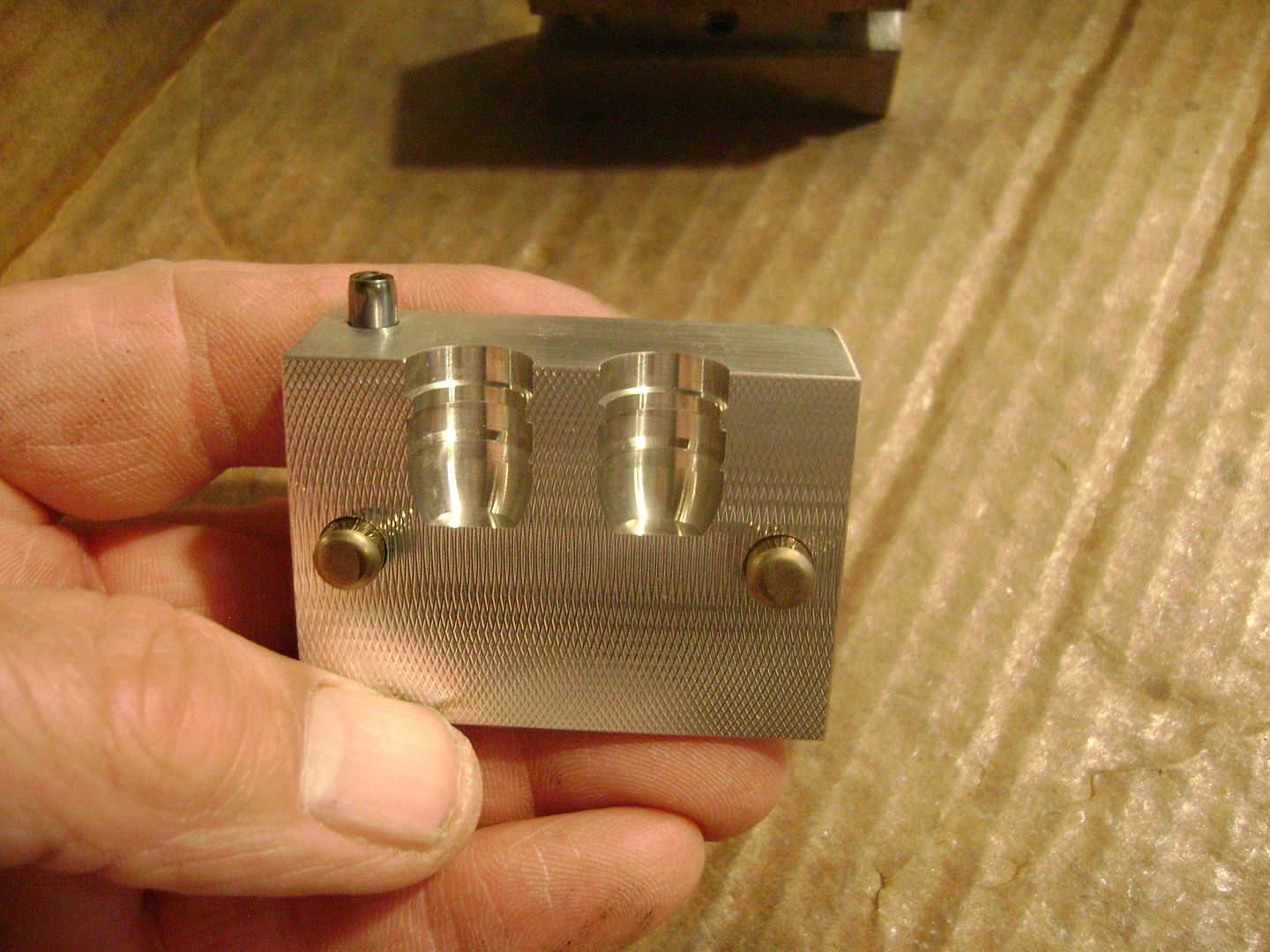

Before cleaning

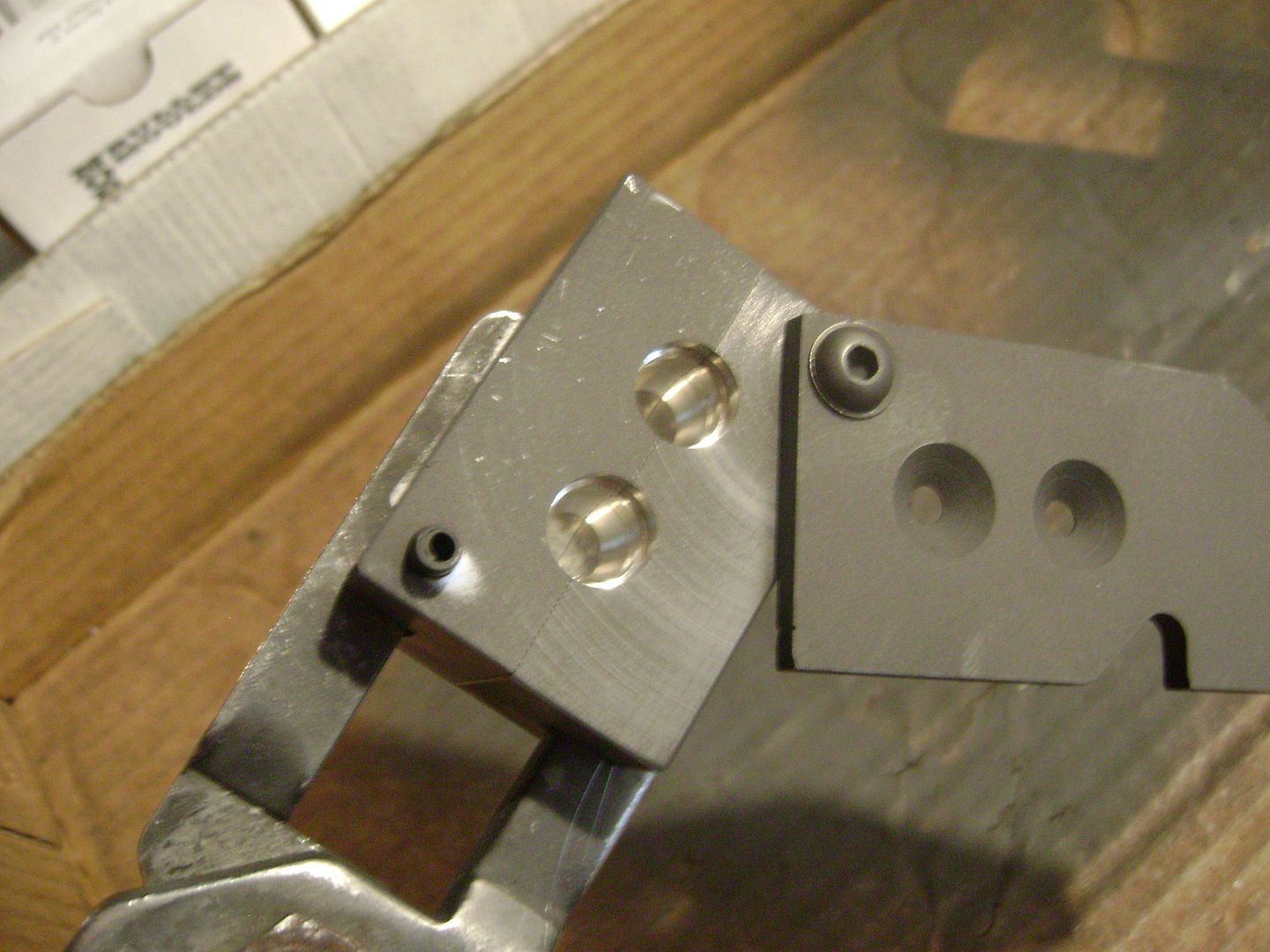

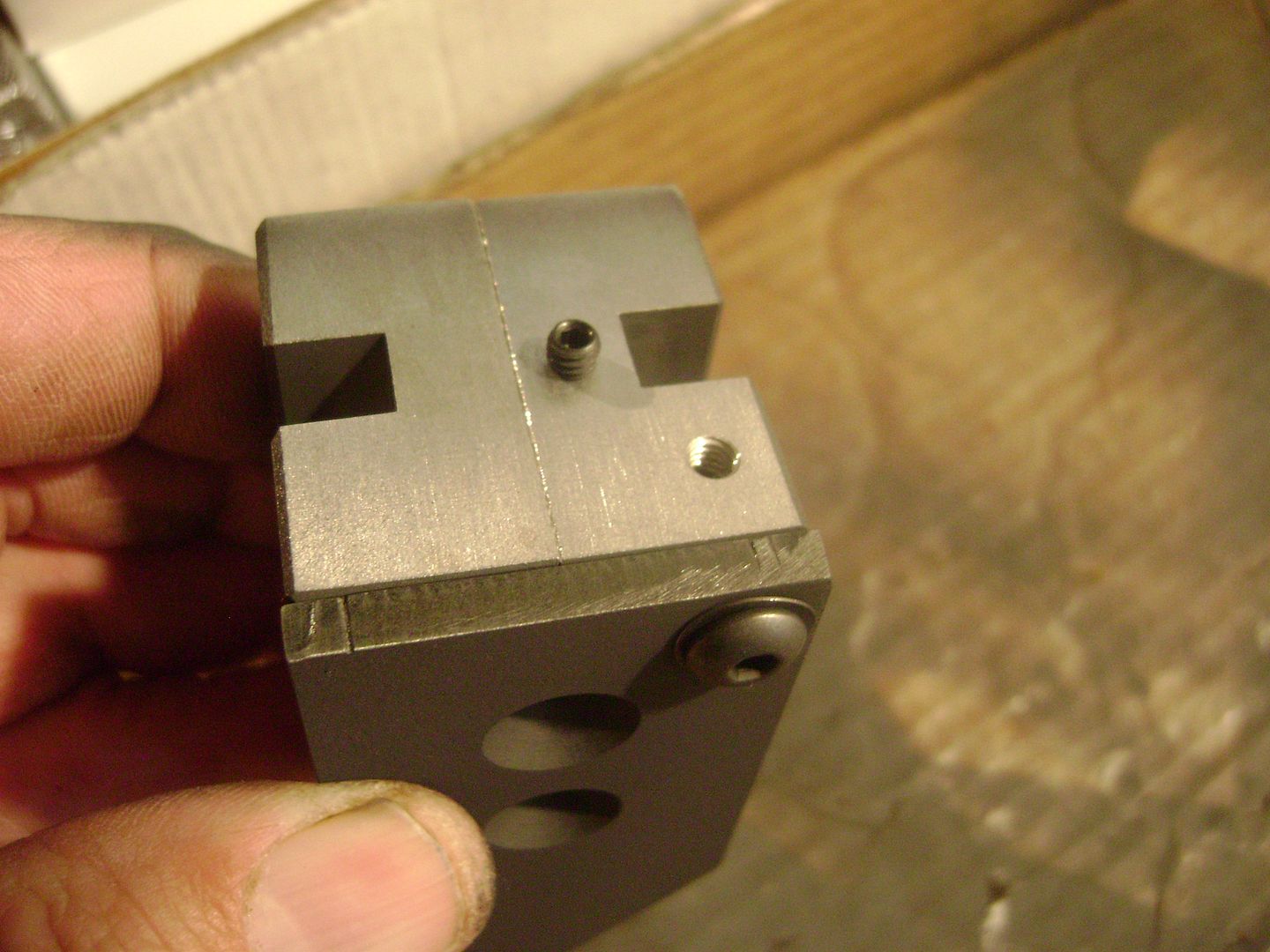

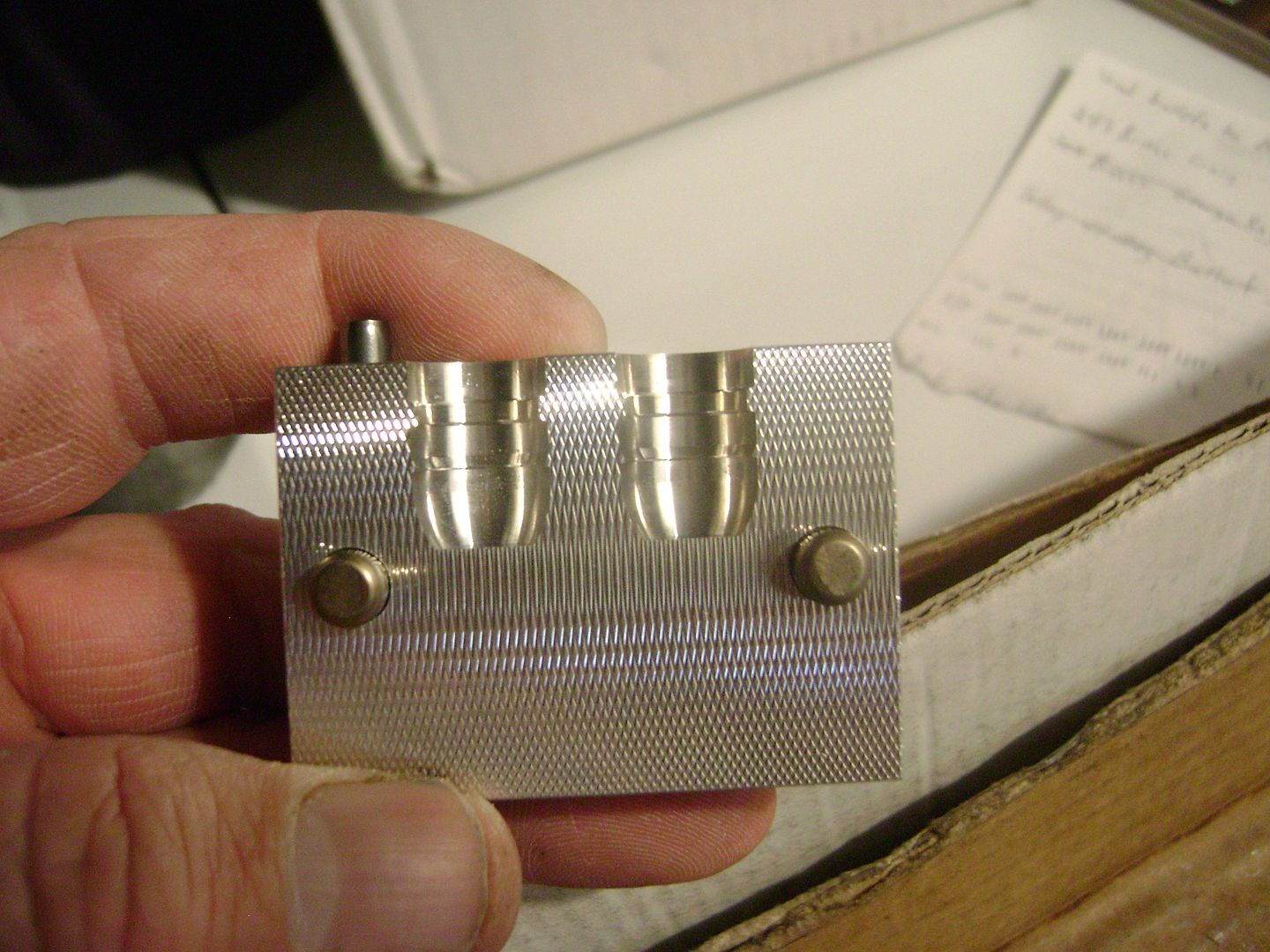

After

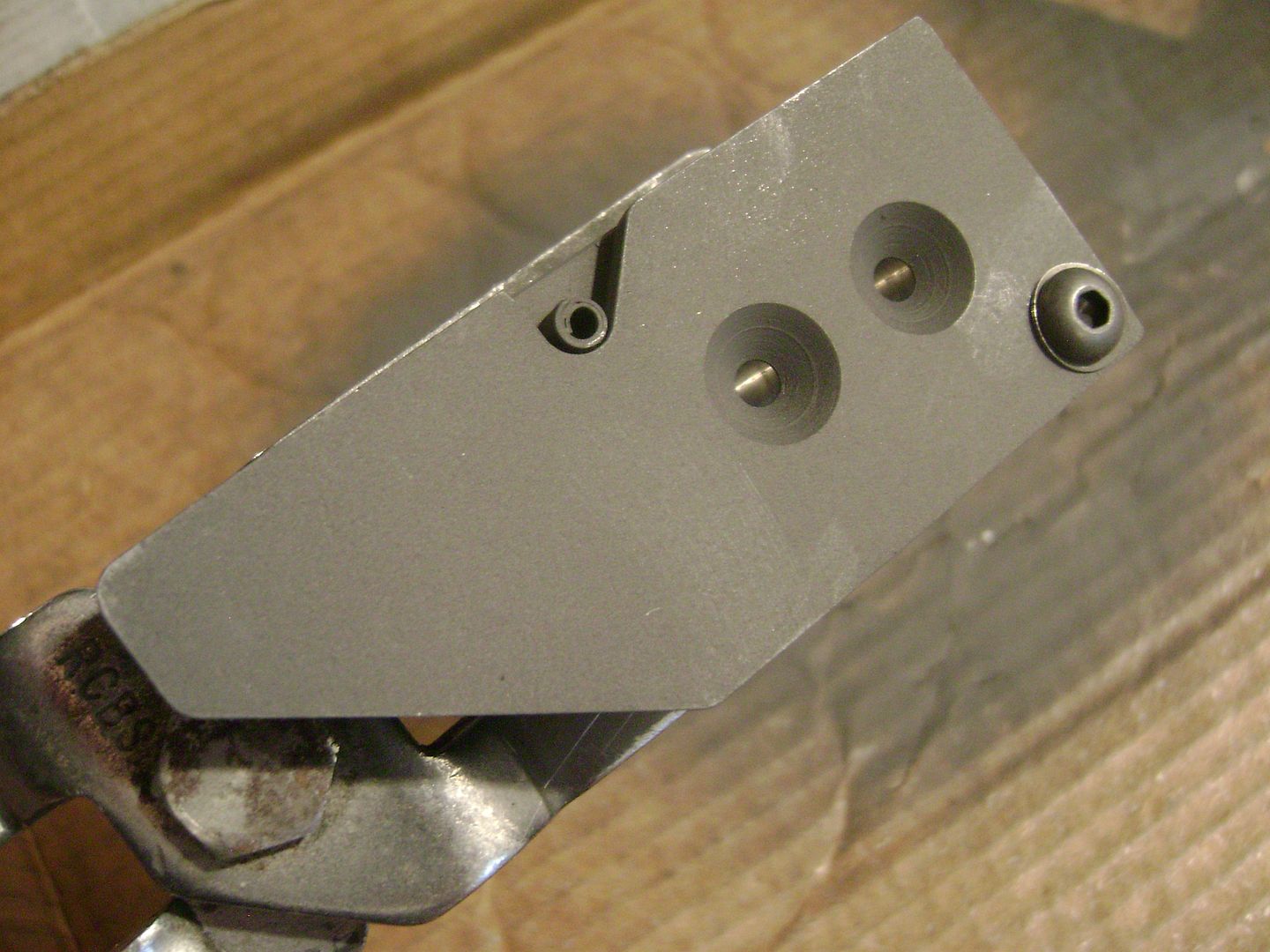

I coated the top of the blocks & both sides the sprue plate with Frankford Arsenal Drop Out, installed the plate, adjusted & replaced the set screw.

Continued

Open her up & took a look. The blocks were clean, no burrs or out of place tool marks. The cavities were beautiful. Removing the sprue plate, screw & set screw I gave the blocks a going over with a nylon brush & hot soapy water. She looked good. The sprue plate was cleaned with starting fluid & brush.

Before cleaning

After

I coated the top of the blocks & both sides the sprue plate with Frankford Arsenal Drop Out, installed the plate, adjusted & replaced the set screw.

Continued