Well if you look over at the

Hollow Point Molds you will see that Eric has started working with the new style Lee 2 cavity molds.

Just a suggestion here, but you could easily pick up one of the Lee 2 cavity in a HPed version, and also add the same in a 6 cavity solid to your collection. This way, you would have a good supply of solids for working up your loads and simply piddling around, but have the same bullet in a HP version for when your out looking for yote's or other type critters. With the 357's it's not like your looking at a big spread in the weights between the two and more than likely the same load can be used for both with equal or possibly even better results.

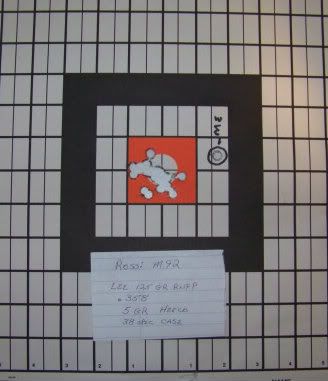

Just look them over and try to pick one that has the rounded nose and a decent flat point like those pictured above. They should feed smoother in that profile no matter if they are solids or HP's. I can tell you the 158 RF is a decent bullet, and if your really don't want the beveled base on it, it doesn't take a lot to make it go away, especially if your going to have it worked over into a HP version. Another one that wasn't suggested is the 150gr RN. While it might not be the prettiest shape for a solid hunting bullet, it would feed great, and in the HP version you would end up with a nice wide frontal area when it expands, and have plenty of shoulder there to hold it together.

Just a side not here to the HP's I have played with. I personally have found that if you want a really good HP to work well and not have fracturing, or have them blow the noses off as they expand, look for the ones with a longer profile to them. The smaller the caliber the more important this is. I have them in mold from .308 up through my 45's and the best functioning ones are the RFN type to start with. THey have that long radius on them which will support the nose s it rolls back, where the ones like the SWC type have a sharper profile and don't add as much support. This type will work, but it is a lot harder to keep the mushrooming ring from separating as it rolls back towards the shank in the smaller calibers. If you look at some of my pictures you will see what I am talking about. I have some of the RFN type HPs which have rolled all the way back to the bases, and some of the SWC type which did so as well, but they started out with a big wide base and/or small hp cavity for their diameter. The 358-640 MP mold I have took a bit of trial and error to keep things together. Initially I couldn't get much past 38 SPL type velocities without loosing he noses. I managed to get them up into the 1300'ish FPS range and hold together, but it took some playing with the alloy to do so.

The other thing you also have to contend with is leading. You might have a softer alloy that expands wonderfully, but when you crank up the velocity it will lead like the devil. You have to have an alloy with a little bit of antimony, and an equal amount of tin to balance it, and the remainder of lead. My higher velocity alloy is using about 1.75% tin and antimony, and the remainder pure lead. This is for mid ranged magnum handgun velocity though. For that rifle you might have to play with something in a 2/2/96 or so to get them to work like you want. You have to have them hard enough to hold the lands in the barrel but also pliable enough to expand without fracturing.

You will read enough times while researching the alloy for pouring HP's that antimony is something you don't want. To a point I can go along with that statement. However it has been my experience with using an alloy already containing it that it isn't the deal killer that most make it out to be. You simply have to balance it with tin in order to end up with the alloy being pliable and malleable. This allows it to be hard enough for the higher pressures and velocities, while at the same time letting it flow instead of shattering when it hits something.

Good luck hope that helps.