Yeah, we both fell from the same tree, at the same time, and landed in the same thorn bush, then rolled into a salt bath. It was quite miserable for both of us.

I was the guy you two landed on...

----

The obvious is the bullet moves forward and hits the lands, hesitates while pressure builds and swells the case, then the bullet continues down the barrel.

Keep in mind the 'Wylde' chamber closes up 'Bullet Jump' (Free Bore) some so bullet is hitting rifling sooner than it would in a 5.56mm chamber.

Two things come to mind, one is the chamber has to be allowing the brass to oversize in the areas indicated. If the chamber wasn't oversize the brass couldn't swell.

I get shouted down every time I suggest chambers should be cut in steps instead of gouged out with a one piece reamer.

The second thing is I'd watch brass from this rifle closely. This has to be overworking the brass at a point that commonly splits anyway.

A good argument for annealing, but for brass that didn't take a lot of prep (flash hole, primer pocket sizing, neck turning, etc) I'm not sure I would mess with it...

Probably just load/shoot a few times & discard when cracks started to show up in the batch.

----

Uncle Nick has some GREAT stuff!

I have seen exactly what he shows with the mouth curling inward, and it's often more pronounced on roll crimp cases. Don't ask me why the roll crimp would make it curl more, but it seems to.

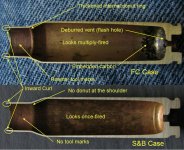

That's a great cut away comparison between once fired & loaded several times.

It really shows what goes on when the brass is loaded several times, and particularly when the brass is loaded 'Hot'.