Hi All. I havent been here since last year when I had a problem firing a small cannon which I had made at my work. Thanks to you guys I sorted that out. Heres the latest one Ive made,its a mortar with a 43mm bore[golf ball] and its about 8 inches long. Ive shot it a few times but it just doesnt want to go really BANG!!!.The small 3/4 inch bore x15 inch cannon I made before gives a real kick in the guts detonation, but this one just seems to go boom?.Its bored 43mm dia for the main barrel and then 20mm dia for the last 1 inch where the powder goes. I wrap the golf ball in tissue paper so its a nice tight fit... Im using homemade BP 75-15-10 which I ball mill and then granulate fairly fine. I know the powder is not the problem but I read on the Net that mortars need meal powder and loose wadding to work best? Any Ideas Anyone? Im looking forward to any suggestions on how to get that sonic bang from my mortar.Bye from AUSTRALIA

from my mortar.Bye from AUSTRALIA

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Latest little cannon

- Thread starter sam0812

- Start date

troy_mclure

New member

sounds like the ball is leaving the barrel to soon, so it needs to be heavier, or tighter.

try a greased cloth patch.

or you can drill a hole thru the golf ball, seal 1 end with epoxy, fill with lead shot(or any heavy metal) and epoxy it closed.

try a greased cloth patch.

or you can drill a hole thru the golf ball, seal 1 end with epoxy, fill with lead shot(or any heavy metal) and epoxy it closed.

simonkenton

New member

You are a wild man!

A home made cannon!

I don't know anything about cannons but I would like to light that thing off if you get it to working right.

A home made cannon!

I don't know anything about cannons but I would like to light that thing off if you get it to working right.

Ive filmed it going off with a digital camera,I can 'freeze frame' it where the ball is about 3 ft out of the barrel,followed by a huge sheet of flame.I figure most of the powder is being burnt outside the muzzle. I load about 2 big teaspoonfuls of powder .The ball goes clean out of sight BUT it doesnt seem loud enough .I know over there "salute cannons ' are popular,they seem to be about the same size,shape as mine but how do they get the noise. Would really fine powder help? Should I 'patch' the ball to a REALLY tight fit? Anyhow any suggestions greatly appreciated SAM

.I know over there "salute cannons ' are popular,they seem to be about the same size,shape as mine but how do they get the noise. Would really fine powder help? Should I 'patch' the ball to a REALLY tight fit? Anyhow any suggestions greatly appreciated SAM

madcratebuilder

New member

That is some nice machine work.

sundance44s

New member

Try a soda can / beer can filled with concrete ....a buddy of mine shoots out of his , its a big boom good ...good fit , some cans are a little different size than others , but you might can find one with a good fit ...you can also fill the cans with sand , but stand way back , its like a sand blaster .

Golf Ball

A couple of things:

Here's a little Golf Ball Mortar that I made.

Disassembled:

It has a bore of 1.746" (44.348mm) and a overall length of four inches. Deducting for the length if the breech plug, the interior length of the bore is about 2.5 inches (63mm). There is a formula for bore length for BP mortars - something between 1.5 to 2 times the diameter of the ball.

I use anywhere from 20 grains to 85 grains of Fg black powder.

Note: Mortars, properly loaded, do not make the kind of sound that you are looking for. They make the sound that you are getting - a "Boom".

These little mortars function perfectly well using Fg or Cannon grade BP.

NO wadding. Wadding raises pressure. Mortars do not use wadding, the fit is supposed to be loose - that "slop" is called windage and is, again, supposed to be there. No wadding, no tissue paper - the ball just drops in and sits on the powder.

Boom!

The little guy pictured will throw GBs some hundreds of yards when loaded up. I rarely do that for this one as the walls are a bit thin. Another GB mortar that I have - loaded with the same procedures and more BP - shoots them quite far.

Pete

I wrap the golf ball in tissue paper so its a nice tight fit... Im using homemade BP 75-15-10 which I ball mill and then granulate fairly fine. I know the powder is not the problem but I read on the Net that mortars need meal powder and loose wadding to work best? Any Ideas Anyone? Im looking forward

A couple of things:

Here's a little Golf Ball Mortar that I made.

Disassembled:

It has a bore of 1.746" (44.348mm) and a overall length of four inches. Deducting for the length if the breech plug, the interior length of the bore is about 2.5 inches (63mm). There is a formula for bore length for BP mortars - something between 1.5 to 2 times the diameter of the ball.

I use anywhere from 20 grains to 85 grains of Fg black powder.

Note: Mortars, properly loaded, do not make the kind of sound that you are looking for. They make the sound that you are getting - a "Boom".

These little mortars function perfectly well using Fg or Cannon grade BP.

Absolutely not.Should I 'patch' the ball to a REALLY tight fit?

NO wadding. Wadding raises pressure. Mortars do not use wadding, the fit is supposed to be loose - that "slop" is called windage and is, again, supposed to be there. No wadding, no tissue paper - the ball just drops in and sits on the powder.

Boom!

The little guy pictured will throw GBs some hundreds of yards when loaded up. I rarely do that for this one as the walls are a bit thin. Another GB mortar that I have - loaded with the same procedures and more BP - shoots them quite far.

Pete

Last edited:

Congratulations, that's a very nice looking piece of work!

Might not the 20mm "combustion chamber" be a the heart of the problem (if there really is a problem) -- won't transitioning from the 20mm chamber to the 43mm bore cause a significant pressure drop? You seem to have reversed the principal of the bottle-necked cartridge.

On a political note: Do you make your own BP by choice, or have Australia's new gun regulations made it unavailable or prohibitively expensive?

Might not the 20mm "combustion chamber" be a the heart of the problem (if there really is a problem) -- won't transitioning from the 20mm chamber to the 43mm bore cause a significant pressure drop? You seem to have reversed the principal of the bottle-necked cartridge.

On a political note: Do you make your own BP by choice, or have Australia's new gun regulations made it unavailable or prohibitively expensive?

basically all firearms,weapons and even fireworks are banned here. you even need a full gun license for an air rifle.If you could be bothered going thru all the hoops to get a gun license you have to regularly shoot at a gun club,get gun safes and the police can search your house at any time without notice.So now only criminals are armed.

Cannon and Mortar fora

Sam0812: Maybe you know about these two "other" fora. If not, both are dedicated BP cannon and mortar fora.

http://www.go2gbo.com/forums/index.php/board,88.0.html

and

http://www.muzzleloadingforum.com/fusionbb/showforum.php?fid/20/

Lots of info. Lots of links specific to what you are doing.

Pete

Sam0812: Maybe you know about these two "other" fora. If not, both are dedicated BP cannon and mortar fora.

http://www.go2gbo.com/forums/index.php/board,88.0.html

and

http://www.muzzleloadingforum.com/fusionbb/showforum.php?fid/20/

Lots of info. Lots of links specific to what you are doing.

Pete

Head-Space

Moderator

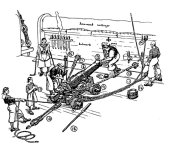

Barrel from 1" "drawn over mandrel" (DOM) seamless, high pressure steam tubing. 3/4" wall. Trunnions are 1 1/8" round stock, jigged and welded. Breech plug was "engineered" by a neighbor, Cert. Structural Engineer. He calculated diameters. We heated the barrel red hot in the BBQ, chilled the plug in liquid nitrogen and drove them together. Pressure welded at the molecular level.

I've since trimmed the trunnions flush with the width of the carriage.

Fully rigged per naval diagrams --

I've modified the touch-hole with a 1/4" counter-sink. This affords ignition using pistol BP sitting in the counter-sink. Either cannon fuse, or powder ignition with a BBQ lighter.

Carriage is red oak from a salvaged old office desk. Stainless, brass, and bronze hardware from the local industrial / marine supply. Mild steel angle iron for the quoin rails. Mild steel strap for the trunnion caps, cold forged (small sledge, and a mandrel in a vice).

Wheels are some sort of plastic round stock from the industrial / marine supply. 1/2" steel axle, galvanized washer/spacers, cotter keys.

It shoots lead ball, "cannon ball sinkers." 3 oz. or 4 oz. -- either just undersized and patched or slightly oversized and swedged down the bore.

Mostly I shoot blank, salutes -- 500 gr. Fg. or FFg. (35 mm film can). TP wadding. The boom rattles windows, smoke cloud the size of a school bus.

Neighbors refer to me affectionately as, "The nut on the ridge with the cannon."

I've since trimmed the trunnions flush with the width of the carriage.

Fully rigged per naval diagrams --

I've modified the touch-hole with a 1/4" counter-sink. This affords ignition using pistol BP sitting in the counter-sink. Either cannon fuse, or powder ignition with a BBQ lighter.

Carriage is red oak from a salvaged old office desk. Stainless, brass, and bronze hardware from the local industrial / marine supply. Mild steel angle iron for the quoin rails. Mild steel strap for the trunnion caps, cold forged (small sledge, and a mandrel in a vice).

Wheels are some sort of plastic round stock from the industrial / marine supply. 1/2" steel axle, galvanized washer/spacers, cotter keys.

It shoots lead ball, "cannon ball sinkers." 3 oz. or 4 oz. -- either just undersized and patched or slightly oversized and swedged down the bore.

Mostly I shoot blank, salutes -- 500 gr. Fg. or FFg. (35 mm film can). TP wadding. The boom rattles windows, smoke cloud the size of a school bus.

Neighbors refer to me affectionately as, "The nut on the ridge with the cannon."

Attachments

I like that a lot . i put some pics of the last one I built,its 4130 steel,9/16 " bore .It goes severely BANG with a patched .50 lead ball.The only thing is the wall thickness is not as thick as maybe it should be .Its at least 10mm thick at its thinnest points,but how does this compare to muzzle loader pistols,rifles etc Should I be concerned? I get well away when firing . Its just that the cannon websites are saying the walls have to be at least as thick as the bore?!?!. Anyhow any comments greatly appreciated THANKS SAM

Anyhow any comments greatly appreciated THANKS SAM

Attachments

10mm is .393 inches thick which should be plenty thick.

I have a Pedersoli factory made 13/16" octagon .50 caliber rifled barrel. That equals .8125 inches measured across the flats.

Subtracting the .50 bore diameter leaves a wall thickness of about .3125" which is still considerably less than the thickness of your barrel.

I have no fears at all about the wall strength of my Pedersoli barrel when shooting 90 - 100 grain powder charges with it. Yet most companies will only offer that diameter barrel in .45 caliber or less. Go figure!

I have a Pedersoli factory made 13/16" octagon .50 caliber rifled barrel. That equals .8125 inches measured across the flats.

Subtracting the .50 bore diameter leaves a wall thickness of about .3125" which is still considerably less than the thickness of your barrel.

I have no fears at all about the wall strength of my Pedersoli barrel when shooting 90 - 100 grain powder charges with it. Yet most companies will only offer that diameter barrel in .45 caliber or less. Go figure!

Attachments

Last edited:

Head-Space

Moderator

Breech wall thickness equal to diameter of the bore is the rule of thumb in CAST cannon, even with bore sleeve liners.

I don't have any pat answers for wall requirements for cannon. DOM high-pressure steam tubing is pretty sophisticated stuff. It's not mild steel "water pipe."

The friend who turned my tube asked if I wanted some "shape" -- taper, bands, etc. I specified "I want wall thickness. Don't remove any wall material."

We produced a second tube, "proof fired" it with a mix of BP and smokeless (I know, it's against all the rules.) We loaded it with about a quadruple charge (2,000 gr) and stacked lead ball out to the muzzle, about five as I recall.

Several of these "proof loads" and we finally blew out the breech plug. (In a test bunker.) We ran some X-ray analysis on the tube and no fractures. (We have access to medical diagnostic equipment.)

I've tried backing off the 500 gr. BP load to about 250 gr. It just doesn't "boom" like a cannon at that load. I use it for salutes, not projectiles.

If I were running projectiles, I'd back off the load. But for salutes, 500 gr.

Smoke & noise. At night a huge flame out the muzzle and the touch-hole. 14 salutes in a pound of powder.

I don't have any pat answers for wall requirements for cannon. DOM high-pressure steam tubing is pretty sophisticated stuff. It's not mild steel "water pipe."

The friend who turned my tube asked if I wanted some "shape" -- taper, bands, etc. I specified "I want wall thickness. Don't remove any wall material."

We produced a second tube, "proof fired" it with a mix of BP and smokeless (I know, it's against all the rules.) We loaded it with about a quadruple charge (2,000 gr) and stacked lead ball out to the muzzle, about five as I recall.

Several of these "proof loads" and we finally blew out the breech plug. (In a test bunker.) We ran some X-ray analysis on the tube and no fractures. (We have access to medical diagnostic equipment.)

I've tried backing off the 500 gr. BP load to about 250 gr. It just doesn't "boom" like a cannon at that load. I use it for salutes, not projectiles.

If I were running projectiles, I'd back off the load. But for salutes, 500 gr.

Smoke & noise. At night a huge flame out the muzzle and the touch-hole. 14 salutes in a pound of powder.

video - a .50 cal cannon

Sam, et al: I just found this little video over at the ML forum. The owner is the fellow who designed the little mortar that I provided pictures for earlier.

Enjoy.

http://www.muzzleloadingforum.com/fusionbb/showtopic.php?tid/219579/pid/858406/post/last/m/1/#LAST

Pete

Sam, et al: I just found this little video over at the ML forum. The owner is the fellow who designed the little mortar that I provided pictures for earlier.

Enjoy.

http://www.muzzleloadingforum.com/fusionbb/showtopic.php?tid/219579/pid/858406/post/last/m/1/#LAST

Pete

Thanks darkgael for your reply. Having a bit of trouble getting on to the ML website for some reason ,but I will work on it. I really appreciate the friendly informative INFO I can get here,as its pretty much non existent in Australia. And a BIG THANKS to everyone else who has replied or commented on my original post .head space, articap, zippy, troy, sundance ,madcrate, simon ,codpils I will head back here later on, and catchyas later BYE SAM