You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

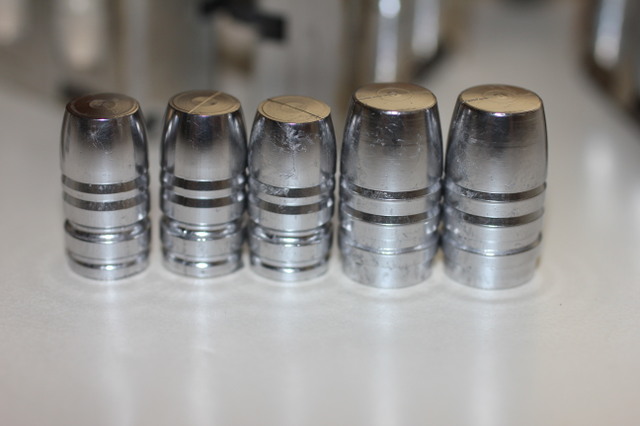

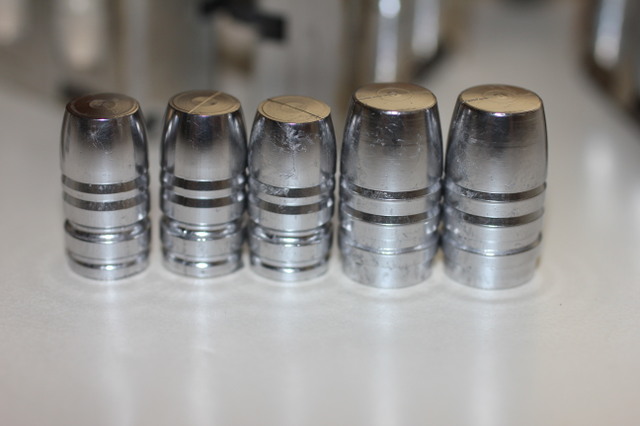

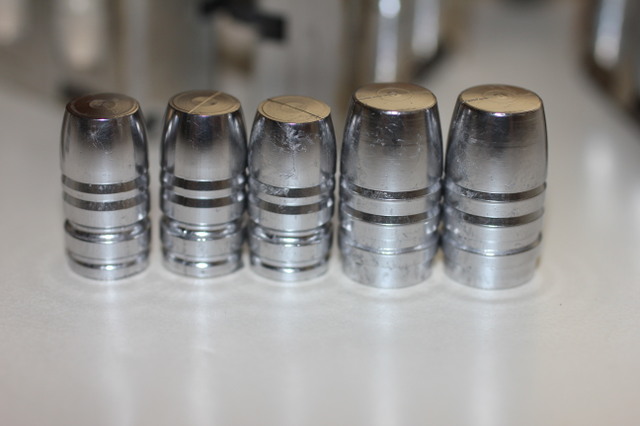

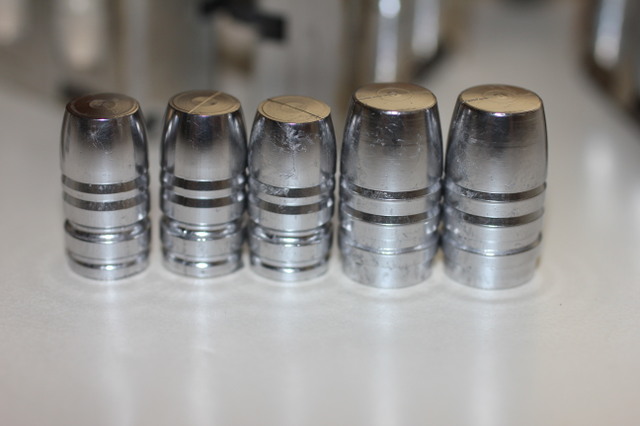

My broken cherries

- Thread starter skizzums

- Start date

Btw. I picked out my shiniest ones cuz they are so pretty. Most seem to have a dull sandy look. I noticed they seemed shinier on a cooler mould. Is there any benefit/consequence to shiny/dull? I figure when I buy them commercially they are always shiny, so that must be the way to go.

FrankenMauser

New member

Commercial operations only sell shiny bullets, because people won't pay as much for frosty bullets.

Functionally, they are the same.**

Hot molds give you frosty bullets. If it works for you, don't worry about it.

If you want shiny bullets, slow down a bit, or see if turning the melt temp down a hair will help.

Almost all of my bullets drop out frosty. It's caused by my casting tempo. Once I get moving, it is hard for me to slow down. So, having to wait longer between pours, for the mold to cool down, doesn't work very well. I'd rather push as fast as the mold will allow me (without overheating), and shoot frosty bullets, than wait longer between pours, just so they look better.

** If some one wanted to be picky, they could get into a discussion about minor bullet variations caused by alloy and mold temperature, such as shrink rates, densities, dendrite formation, etc. But, if your methods are consistent, the bullets will be close enough that it won't matter.

Functionally, they are the same.**

Hot molds give you frosty bullets. If it works for you, don't worry about it.

If you want shiny bullets, slow down a bit, or see if turning the melt temp down a hair will help.

Almost all of my bullets drop out frosty. It's caused by my casting tempo. Once I get moving, it is hard for me to slow down. So, having to wait longer between pours, for the mold to cool down, doesn't work very well. I'd rather push as fast as the mold will allow me (without overheating), and shoot frosty bullets, than wait longer between pours, just so they look better.

** If some one wanted to be picky, they could get into a discussion about minor bullet variations caused by alloy and mold temperature, such as shrink rates, densities, dendrite formation, etc. But, if your methods are consistent, the bullets will be close enough that it won't matter.

I hope they shoot as well for you as they look.

I have poured up a bunch that didn't look that good but like FrankenMauser said, they still shot just fine. IF I was doing all this simply to impress someone I would just cast them out of pure tin or Lino. They would look great, but doubt they would shoot worth a hoot.

I have poured up a bunch that didn't look that good but like FrankenMauser said, they still shot just fine. IF I was doing all this simply to impress someone I would just cast them out of pure tin or Lino. They would look great, but doubt they would shoot worth a hoot.

FrankenMauser

New member

Yep. I mentioned it here, when I grabbed the wrong alloy last year.IF I was doing all this simply to impress someone I would just cast them out of pure tin or Lino. They would look great, but doubt they would shoot worth a hoot.

With a one-cavity brass mold that can't be run very fast, I wasted a lot of time casting bullets that were only good for eye candy.

But, eye candy, Linotype does make...

wow, those sure are pretty though. i was noticing which were shiny and which were dull or "frosty" and started leaving about 20 seconds with the mold open between pours to keep em shiny, but if it doesnt matter, i would rather just do it as quickly as possible. i still need a hollow point mold but everyone is sold out, i used that cheap forester hp drill tool. i know that they most likely will not expand, i just did it for aesthetics. i loaded them all up this morning and all seems well, i am so happy to be able to save another 6-7cents a round pouring my own, hopefully it will pay for the mold and bottom pour and lyman 450 eventually. i figure that will be paid for after about 5-6k rounds. thanks again everyone.

Attachments

Sooo, what do you call frosted?¿ That term has a lot of varied meanings. Are these boolits what you'd call frosted?

How about these;

The first two pics are what I call just right, but some would call them "frosted"

The third pic is what I call frosted. The appearance of antimony crystals on the surface of the boolit. Looks like properly galvanized steel.

Now the above are very shiny. That is a fairly hard mix (17 parts linotype--3 parts pure lead), that when cast with precise heat/alloy temp,* and cooling the two molds on a wet sponge, produced those boolits. The left ones are 300 .452, the right is the 440 gr. 500 .501 mold. Casting using both molds. Alternating them allowed time for them to cool off.

*About the precise temp control, I built a PID temperature controller to control the temp on my Lee 4-20 pot. I don't remember the exact temp, BUT I seldom go over 725 degrees, most likely was right at 700D.

http://photos.imageevent.com/jptowns/bullets/websize/PB080101.JPG[/IMG

[IMG]http://photos.imageevent.com/jptowns/bullets/websize/Picture%20112.jpg

How about these;

The first two pics are what I call just right, but some would call them "frosted"

The third pic is what I call frosted. The appearance of antimony crystals on the surface of the boolit. Looks like properly galvanized steel.

Now the above are very shiny. That is a fairly hard mix (17 parts linotype--3 parts pure lead), that when cast with precise heat/alloy temp,* and cooling the two molds on a wet sponge, produced those boolits. The left ones are 300 .452, the right is the 440 gr. 500 .501 mold. Casting using both molds. Alternating them allowed time for them to cool off.

*About the precise temp control, I built a PID temperature controller to control the temp on my Lee 4-20 pot. I don't remember the exact temp, BUT I seldom go over 725 degrees, most likely was right at 700D.

http://photos.imageevent.com/jptowns/bullets/websize/PB080101.JPG[/IMG

[IMG]http://photos.imageevent.com/jptowns/bullets/websize/Picture%20112.jpg

Last edited:

FrankenMauser

New member

Here's a two-fer.

Frosted, and inclusions:

(I don't know why I was loading bullets with obvious inclusions, but I'm sure there was a good reason. Maybe I was testing to see how much they affected accuracy...)

And, just some frosty bullets...

437 gr RN-FP bore-rider, next to 265 gr Hornady FP - .444 Marlin.

Frosted, and inclusions:

(I don't know why I was loading bullets with obvious inclusions, but I'm sure there was a good reason. Maybe I was testing to see how much they affected accuracy...)

And, just some frosty bullets...

437 gr RN-FP bore-rider, next to 265 gr Hornady FP - .444 Marlin.

Attachments

Yep. I mentioned it here, when I grabbed the wrong alloy last year.

With a one-cavity brass mold that can't be run very fast, I wasted a lot of time casting bullets that were only good for eye candy.

But, eye candy, Linotype does make...

I have a couple hundred pounds of Linotype left, I mix it 50/50 by weight with pure lead and get an alloy that is very suitable for bullets. It's a little more finicky than Lyman #2 IMO but does make good bullets.

50/50 Lino/Pure mix

--------------------

92% Lead

2% Tin

6% Antimony

BHN 15

(I don't know why I was loading bullets with obvious inclusions, but I'm sure there was a good reason. Maybe I was testing to see how much they affected accuracy...)

Sssshhhh don't tell anyone, but I shoot a LOT of solids like that. I haven't noticed them to shoot somewhere besides the target, so figured the hogs wouldn't mind it either.

So far none have brought it to my attention ....

When I got started up I picked up a couple hundred pounds of lino, mono, and some stereo type to use when I get to working with my rifle bullets. I figured between the three of them I would find something that works. One of these days I might even give that a try, but right now I am having too much fun with my revolvers.....

I just looked at my post, and even I'm confused! Apparently one of my pics didn't make it to be seen, so here it is, my example of what I consider frosted.

Apparently one of my pics didn't make it to be seen, so here it is, my example of what I consider frosted.

Now that's frosted!

Frank,now see, those I don't consider frosted. In fact, that's what I shoot for and get when everything's working right. You do have some crud inclusions in that one boolit, but it shouldn't hurt to shoot it.,(Ummm I mean hurt the rifle, it'll damn sure hurt a game animal)! Are those 45/90 or 45/120? Just look a bit longer than my 45/70's.

Skissums, I'd love to have you stop by, but I'd have to spend a week cleaning/storing stuff. I keep getting new things, that spare bedroom isn't getting any bigger! It's spilled out into the rest of the house, no missus, and the dog doesn't complain.

It's spilled out into the rest of the house, no missus, and the dog doesn't complain.

Now that's frosted!

Frank,now see, those I don't consider frosted. In fact, that's what I shoot for and get when everything's working right. You do have some crud inclusions in that one boolit, but it shouldn't hurt to shoot it.,(Ummm I mean hurt the rifle, it'll damn sure hurt a game animal)! Are those 45/90 or 45/120? Just look a bit longer than my 45/70's.

Skissums, I'd love to have you stop by, but I'd have to spend a week cleaning/storing stuff. I keep getting new things, that spare bedroom isn't getting any bigger!

FrankenMauser

New member

I consider them to be lightly to moderately frosted. I would consider the photo you just posted to be 'heavily' frosted. (Seems like the wrong term, but I'm sure you'll understand what I'm thinking.)Frank,now see, those I don't consider frosted. In fact, that's what I shoot for and get when everything's working right. You do have some crud inclusions in that one boolit, but it shouldn't hurt to shoot it.,(Ummm I mean hurt the rifle, it'll damn sure hurt a game animal)! Are those 45/90 or 45/120? Just look a bit longer than my 45/70's.

The loaded rounds are actually .444 Marlin. As long as I pay attention to its short/unique throat, I can get away with ignoring OAL limitations in my Handi-Rifle by using bore-riders. I'm not sure, but I believe the first bullets pictured are Version 3.1 of that design, and the loaded rounds were Version 1. They should weigh in at 437 gr (V.1) and 432 gr (V.3.1), when 'checked and lubed. OAL is 2.930", or 0.400" over normal max length.

I'm currently on Version 3.1. It looks exactly the same, but has slightly different lube groove, body, and nose dimensions.

The cartridge is capable of going further, but the Handi-Rifle hasn't really let me get past 1,900 fps. The stock geometry and light weight make recoil rather brutal, and continually shake the scope loose if I push beyond 1,850 fps. -My target was 2,050 fps, for ~4000 lb-ft of energy. But, even 3,800+ lb-ft at 1,850 fps is better than getting poked in the eye with a sharp stick.

With tin-sweetened Isotope core alloy (~BHN 10), it has a near perfect balance of expansion and penetration.

My wife gets frosted with me every once in a while, but when she is I ain't takin no pictures of it.

Most of the time it is due to being on these boards and listening to those voices that keep telling me I need this or that, and especially the one that repeats, you gotta get one of these molds.......

Most of the time it is due to being on these boards and listening to those voices that keep telling me I need this or that, and especially the one that repeats, you gotta get one of these molds.......