You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

(modern made) low wall vs. high wall pressures

- Thread starter kcub

- Start date

stubbicatt

New member

As a rule of thumb, the "High Wall" is the choice for rifle cartridges with case heads of the .473" or larger, or the "big bore" rimmed cartridges of yesteryear, the "Low Wall" for pistol cartridges or those of 223 sized case heads. Some will say that even the 223 is too much for the "Low Wall" action.

Low Wall:

High Wall:

Notice you can see the profile of the breach block of the Low Wall well above where it engages the receiver mortise. Notice also that the High Wall breach block is completely enveloped in the receiver mortises so that one only sees the spur of the hammer in profile. There are other dimensional differences between these two similar designs, including the thickness of the actions/frames which will affect their strength and durability.

If you look at the portion of the receiver or frame which bears the load of the firing cartridge transmitted to the breach block, vis the axis of the bore, you can see that any significant force against the block in the high wall is transmitted thru the breach block to the mortise in the frame/receiver in more or less a linear fashion. This design is capable of handling a very significant load.

Conversely, when you examine the linear force of the cartridge against the breach block of the low wall, you will see there is no receiver/frame mortise to absorb this force in line with the axis of the chamber. Consequently, the breach block in the Low Wall in effect pivots in the much shorter frame mortise, aft at the point behind the chamber, and forward at the bottom of the legs of the breach block.

While the steel of the breach block *may* be enough to absorb a significant load and transmit it to the frame (the breach blocks are very similar in design and construction between these two designs), this transmission of force is done at the lower end of the legs of the breach block of the Low Wall where it engages the frame, thus peening the surfaces well below the axis of force. The result is a wallowing out of the frame mortises and a gradual decay in the "headspace" of the cartridge due to a breach block which does not keep the cartridge as far in the chamber.

Aside from safety concerns, which are significant, in my experience and opinion, one should use the low wall for mild cartridges, or accept that it will wear prematurely.

What that level of force is which will harm the action I do not know. I understand that modern alloys of steel and such can do much to strengthen this action, but I personally would not choose anything more robust than 223, and would not even do that, if I valued my safety, eyesight, and longevity of the firearm. 22 long rifle, 32-20 (and that family of cartridges) are about the strongest cartridges which I would chamber in the Low Wall.

Low Wall:

High Wall:

Notice you can see the profile of the breach block of the Low Wall well above where it engages the receiver mortise. Notice also that the High Wall breach block is completely enveloped in the receiver mortises so that one only sees the spur of the hammer in profile. There are other dimensional differences between these two similar designs, including the thickness of the actions/frames which will affect their strength and durability.

If you look at the portion of the receiver or frame which bears the load of the firing cartridge transmitted to the breach block, vis the axis of the bore, you can see that any significant force against the block in the high wall is transmitted thru the breach block to the mortise in the frame/receiver in more or less a linear fashion. This design is capable of handling a very significant load.

Conversely, when you examine the linear force of the cartridge against the breach block of the low wall, you will see there is no receiver/frame mortise to absorb this force in line with the axis of the chamber. Consequently, the breach block in the Low Wall in effect pivots in the much shorter frame mortise, aft at the point behind the chamber, and forward at the bottom of the legs of the breach block.

While the steel of the breach block *may* be enough to absorb a significant load and transmit it to the frame (the breach blocks are very similar in design and construction between these two designs), this transmission of force is done at the lower end of the legs of the breach block of the Low Wall where it engages the frame, thus peening the surfaces well below the axis of force. The result is a wallowing out of the frame mortises and a gradual decay in the "headspace" of the cartridge due to a breach block which does not keep the cartridge as far in the chamber.

Aside from safety concerns, which are significant, in my experience and opinion, one should use the low wall for mild cartridges, or accept that it will wear prematurely.

What that level of force is which will harm the action I do not know. I understand that modern alloys of steel and such can do much to strengthen this action, but I personally would not choose anything more robust than 223, and would not even do that, if I valued my safety, eyesight, and longevity of the firearm. 22 long rifle, 32-20 (and that family of cartridges) are about the strongest cartridges which I would chamber in the Low Wall.

Last edited:

impalacustom

New member

In modern 1885's you don't have to worry about the pressures, if it's chambered for it use modern loads and don't worry. In originals the biggest worry about going overpressure is getting the hammer stuck in you head after it breaks off from a blown primer or case. There have been test on originals that were so overpressure the headstamp was unreadable from smearing on the breach face, the action held but the hammer and firing pin didn't.

Use modern 1885s with modern loads and don't worry, if it won't blow up your your bolt action it won't blow up your single shot.

That high wall that stubbicat has a picture of looks like a Cimarron arms, the original Winchester's double set look different.

Use modern 1885s with modern loads and don't worry, if it won't blow up your your bolt action it won't blow up your single shot.

That high wall that stubbicat has a picture of looks like a Cimarron arms, the original Winchester's double set look different.

Last edited:

stubbicatt

New member

Impala custom, that high wall has a serial number dating from 1904. The Winchester name is stamped clear as a bell on the upper tang. It is not however, in original factory condition.

Kcub It is a Winchester chambered in 32-40. It was rebarreled and chambered by Frank Zika some years ago, with a throated barrel for breach seating, 15" pitch and .3225" groove diameter. Shoots a Pope tapered 200 grain bullet with a .324" base band quite well. Mr. Zika passed away earlier this year. (RIP). Mr. Zika made some other modifications to the action including the firing pin and the removal of the half cock notch on the hammer. There are many other modifications, including a hooked buttplate which has been dimensioned to fit my upper arm perfectly. It too has very fine vertical lines cut into the bearing surface to preclude shifting about once it is set.

I do not know the origin of the triggers. They have been on the rifle for as long as I have owned it. I'm sure it has been through many hands in its 111 year lifetime. I was not there to take delivery of the rifle when it left the factory. The trigger shoes have a rough texture which appear to be extremely fine vertical lines cut into the shoe faces. The tactile sensation is magnificent. Even sweaty trigger finger on a hot day does not slip across the face of the trigger shoes. -Whoever put those on there knew what he was about. The nearly vertical main trigger is a joy to use. The attention to detail on every aspect of this rifle bespeaks a gunsmith, or series of gunsmiths, who were masters of their trade.

Beautiful rifle, great shooter. Best trigger I have had on a rifle, and a fast lock time.

They will bury me with this rifle.

Kcub It is a Winchester chambered in 32-40. It was rebarreled and chambered by Frank Zika some years ago, with a throated barrel for breach seating, 15" pitch and .3225" groove diameter. Shoots a Pope tapered 200 grain bullet with a .324" base band quite well. Mr. Zika passed away earlier this year. (RIP). Mr. Zika made some other modifications to the action including the firing pin and the removal of the half cock notch on the hammer. There are many other modifications, including a hooked buttplate which has been dimensioned to fit my upper arm perfectly. It too has very fine vertical lines cut into the bearing surface to preclude shifting about once it is set.

I do not know the origin of the triggers. They have been on the rifle for as long as I have owned it. I'm sure it has been through many hands in its 111 year lifetime. I was not there to take delivery of the rifle when it left the factory. The trigger shoes have a rough texture which appear to be extremely fine vertical lines cut into the shoe faces. The tactile sensation is magnificent. Even sweaty trigger finger on a hot day does not slip across the face of the trigger shoes. -Whoever put those on there knew what he was about. The nearly vertical main trigger is a joy to use. The attention to detail on every aspect of this rifle bespeaks a gunsmith, or series of gunsmiths, who were masters of their trade.

Beautiful rifle, great shooter. Best trigger I have had on a rifle, and a fast lock time.

They will bury me with this rifle.

Last edited:

I have not attempted any sort of a structural analysis on my BPCR M1885 High Wall. A rough and crude analysis would require measuring receiver wall thickness, (the thinnest part) and figuring out the load path through the dropping block. I think such an analysis a waste of time for my purposes as it is obvious by looking at the thing, these rifles are extremely strong.

Many of these historical actions are, when made of modern steels, extremely strong. While I think the Remington Rolling block an ingenious action, I do not think it a strong action as the load is carried through those action pins. And, the action has zero features to protect the shooter from gas release. I have looked at a number of early single shot action designs, and from memory, they all appear to be very strong. I can say the Martini-Henry is a very strong and safe action.

The problems with these early actions were the materials of the day. These things were made out of plain carbon steels which were extremely soft, then case hardened for a wear surface. Considering they used black powder, the materials were fine for those low pressure cartridges. I find it interesting to read, that if the chambers of black powder rifles are greasy or wet, when a black powder cartridge is fired, the case is pulled up into the throat of the rifle due to the strength of the bullet crimp. There is just not enough pressure to fix the case to the chamber walls due to the low pressures created by black powder combustion. Another issue with the materials of the day is their inconsistency. Vacuum tube technology started about 100 years ago and it did not instantaneously spread to manufacturing facilities. Springfield Armory produced 1,000,000 brittle M1903's, from 1903 and 1917, because Springfield Armory was not using temperature gages in the forge or heat treatment departments . Where heat was applied, the temperature was judged by eyeballs. The end result was that at least 1/3 of the receivers produced in this period were overheated and are so brittle that a sharp impact will cause them to shatter. The other 2/3 rds of receivers were so suspect, that an Army board recommended scrapping all of these receivers in 1927.

The steel manufacturer's of the day similarly lacked gages or process controls and therefore any metallurgical analysis I have read of historical steels indicate a lot of slag, impurities, and unwanted elements in the steel.

As an example of unwanted containments in the steels of the age, this is a 1996 "core" assay of a generic WW-I era 1898 Mauser receiver:

Carbon: 0.29%

Sulfur: 0.022%

Phosphorus: 0.019%

Manganese: 0.45%

Silicon: 0.16%

Nickel: 0.05%

Chromium 0.02%

Molybdenum: <0.01% (trace)

Vanadium <0.01% (trace)

Copper 0.17%

Columbium: <0.01% (trace)

The 1996 "core" assay of a WW-I era 1898 Mauser bolt:

Carbon: 0.18%

Sulfur: 0.018%

Phosphorus: 0.014%

Manganese: 0.76%

Silicon: 0.23%

Nickel: 0.29%

Chromium: 0.06%

Molybdenum: <0.01% (trace)

Copper 0.15%

Aluminum: 0.02%

This is the German material specification:

source: Rifle and Carbine 98 Dieter Storz

Barrels and Receivers:

Carbon LT EQ 0.40%

Silicon LT EQ 0.30%

Manganese LT EQ 0.90

Phosphorus LT EQ 0.04%

Sulfur LT EQ 0.06%

Copper LT EQ 0.18%

The nickel, aluminum, chromium, molybdenum, vanadium, columbium are containments that crept into the steel ladle, either through scrap, or in the natural ore and the Germans were not able to remove them by blowing oxygen through the steel, as was done during the Bessemer process. The copper is in there to make the steel easier to machine, but copper in steel weakens it. A spectrum of unwanted elements and slag is a characteristic of the plain carbon steels of the late 19th and early 20th century.

So, the summary of this, the same historical action designs, made of modern alloy steels, made on modern productions lines, with modern process controls, are going to be more consistent in material properties and stronger than when they were first designed and manufactured 125 years ago.

I know modern high wall M1885 actions were made in 30-06 and 270 Win, so these actions are plenty strong. I also suspect the low wall is a very strong action, but I don't have a low wall to examine.

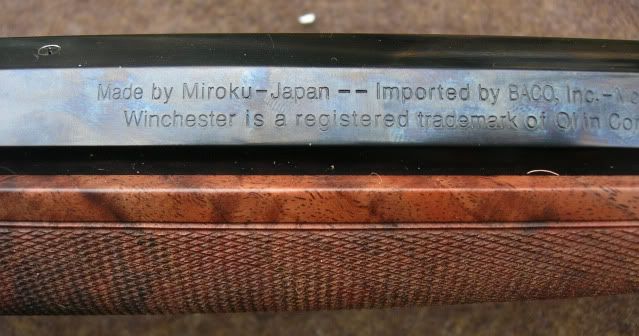

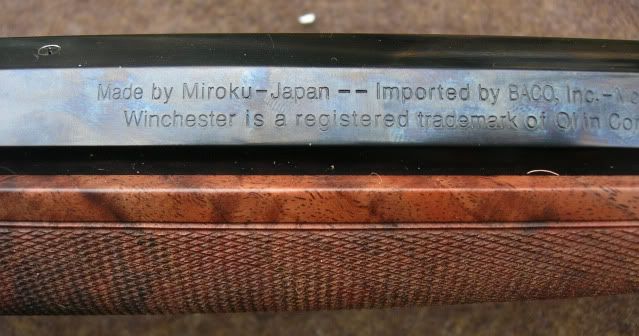

Anyway, my Japanese made M1885 is a beatiful, finely built rifle and I have no doubt that I could shoot very heavy 45/70 loads in it, loads that would probably create excess headspace in historic M1885 actions.

The limiting factor is the load the structure is carrying. Multiply psia by surface area and come up with pounds force. A 260 Rem cartridge is much wider, longer, has a greater head diameter than a 223. So while the 260 Rem and 223 Rem both operate at similar pressures, the 260 Rem puts much more load on the structure. If the action is safe for 260 Rem, than any cartridge which puts an equal or less load, should be perfectly safe.

Many of these historical actions are, when made of modern steels, extremely strong. While I think the Remington Rolling block an ingenious action, I do not think it a strong action as the load is carried through those action pins. And, the action has zero features to protect the shooter from gas release. I have looked at a number of early single shot action designs, and from memory, they all appear to be very strong. I can say the Martini-Henry is a very strong and safe action.

The problems with these early actions were the materials of the day. These things were made out of plain carbon steels which were extremely soft, then case hardened for a wear surface. Considering they used black powder, the materials were fine for those low pressure cartridges. I find it interesting to read, that if the chambers of black powder rifles are greasy or wet, when a black powder cartridge is fired, the case is pulled up into the throat of the rifle due to the strength of the bullet crimp. There is just not enough pressure to fix the case to the chamber walls due to the low pressures created by black powder combustion. Another issue with the materials of the day is their inconsistency. Vacuum tube technology started about 100 years ago and it did not instantaneously spread to manufacturing facilities. Springfield Armory produced 1,000,000 brittle M1903's, from 1903 and 1917, because Springfield Armory was not using temperature gages in the forge or heat treatment departments . Where heat was applied, the temperature was judged by eyeballs. The end result was that at least 1/3 of the receivers produced in this period were overheated and are so brittle that a sharp impact will cause them to shatter. The other 2/3 rds of receivers were so suspect, that an Army board recommended scrapping all of these receivers in 1927.

The steel manufacturer's of the day similarly lacked gages or process controls and therefore any metallurgical analysis I have read of historical steels indicate a lot of slag, impurities, and unwanted elements in the steel.

As an example of unwanted containments in the steels of the age, this is a 1996 "core" assay of a generic WW-I era 1898 Mauser receiver:

Carbon: 0.29%

Sulfur: 0.022%

Phosphorus: 0.019%

Manganese: 0.45%

Silicon: 0.16%

Nickel: 0.05%

Chromium 0.02%

Molybdenum: <0.01% (trace)

Vanadium <0.01% (trace)

Copper 0.17%

Columbium: <0.01% (trace)

The 1996 "core" assay of a WW-I era 1898 Mauser bolt:

Carbon: 0.18%

Sulfur: 0.018%

Phosphorus: 0.014%

Manganese: 0.76%

Silicon: 0.23%

Nickel: 0.29%

Chromium: 0.06%

Molybdenum: <0.01% (trace)

Copper 0.15%

Aluminum: 0.02%

This is the German material specification:

source: Rifle and Carbine 98 Dieter Storz

Barrels and Receivers:

Carbon LT EQ 0.40%

Silicon LT EQ 0.30%

Manganese LT EQ 0.90

Phosphorus LT EQ 0.04%

Sulfur LT EQ 0.06%

Copper LT EQ 0.18%

The nickel, aluminum, chromium, molybdenum, vanadium, columbium are containments that crept into the steel ladle, either through scrap, or in the natural ore and the Germans were not able to remove them by blowing oxygen through the steel, as was done during the Bessemer process. The copper is in there to make the steel easier to machine, but copper in steel weakens it. A spectrum of unwanted elements and slag is a characteristic of the plain carbon steels of the late 19th and early 20th century.

So, the summary of this, the same historical action designs, made of modern alloy steels, made on modern productions lines, with modern process controls, are going to be more consistent in material properties and stronger than when they were first designed and manufactured 125 years ago.

I know modern high wall M1885 actions were made in 30-06 and 270 Win, so these actions are plenty strong. I also suspect the low wall is a very strong action, but I don't have a low wall to examine.

Anyway, my Japanese made M1885 is a beatiful, finely built rifle and I have no doubt that I could shoot very heavy 45/70 loads in it, loads that would probably create excess headspace in historic M1885 actions.

260 had 60k max psi similar to 5.56 which most everybody shoots all day everyday in 223 rifles.

So is that a good max rule of thumb, 60k psi?

The limiting factor is the load the structure is carrying. Multiply psia by surface area and come up with pounds force. A 260 Rem cartridge is much wider, longer, has a greater head diameter than a 223. So while the 260 Rem and 223 Rem both operate at similar pressures, the 260 Rem puts much more load on the structure. If the action is safe for 260 Rem, than any cartridge which puts an equal or less load, should be perfectly safe.

Last edited: