db creekside

Inactive

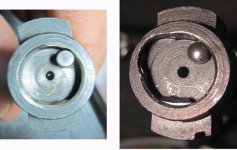

Here is an image of a typical .308 case from my Model 700. From what I've read I have an extractor problem. After about 5 - 6 rounds the bolt is really hard to close until I clean out the little brass shavings from the chamber face and the bolt face (bolt face image also attached). That's Remington brass and this has been a problem from the start.

The rifle has little more than 100 rds thru it but is over 12 years old... that's another problem... recently somewhat solved by finding a place to shoot!

Anyway, I'm hoping to learn from the experience others have had with this issue and what might be some possible solutions.

Thanks in advance!

The rifle has little more than 100 rds thru it but is over 12 years old... that's another problem... recently somewhat solved by finding a place to shoot!

Anyway, I'm hoping to learn from the experience others have had with this issue and what might be some possible solutions.

Thanks in advance!