You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mihec mold question

- Thread starter Swampman1

- Start date

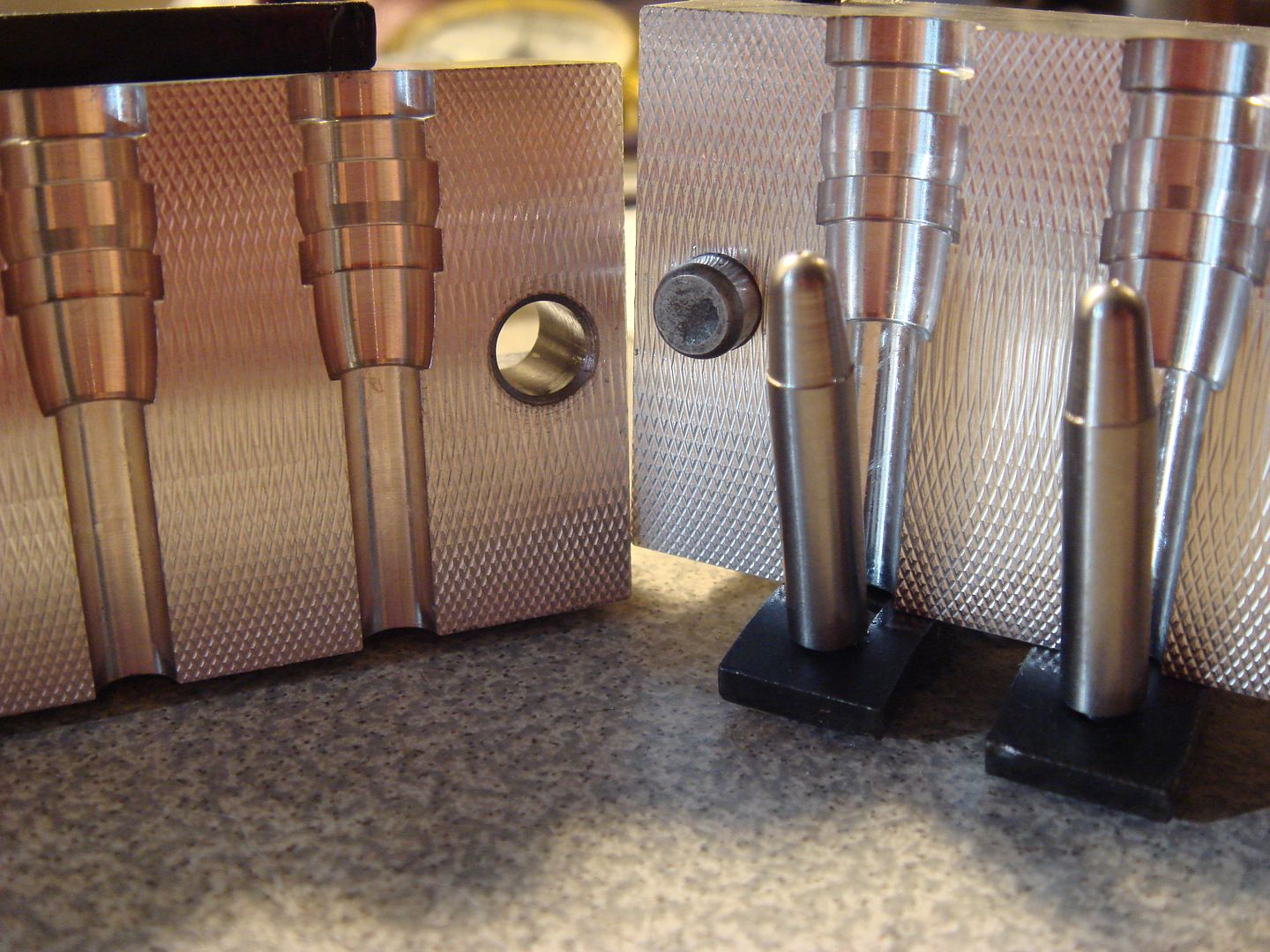

This is Cramer style....the HP pins slide into the cavity to pour and away for dumping the bullets, using some smaller pins that go through the mold blocks.

This is the back of the block.

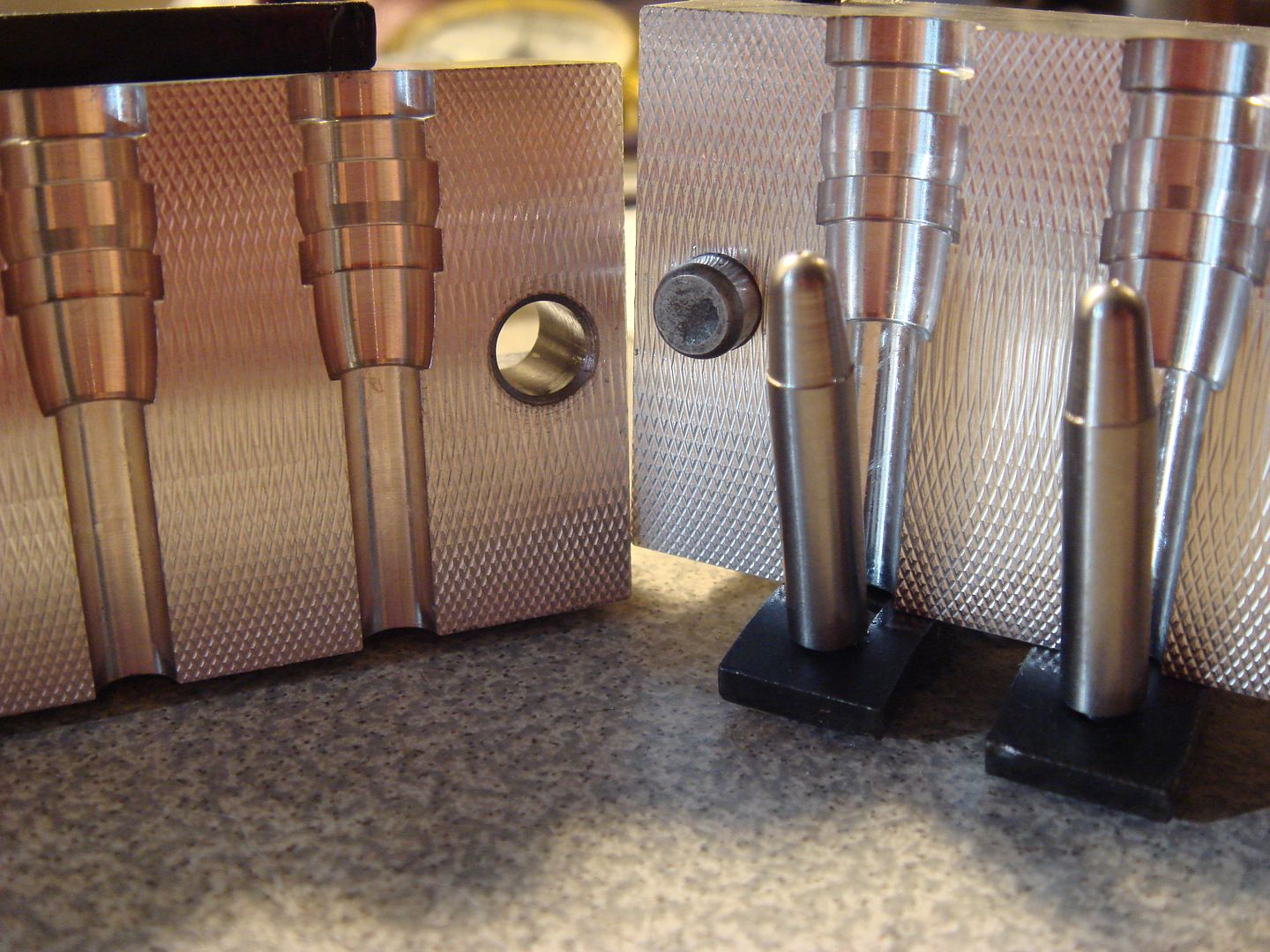

This is NOE's RG system.

There are also Inset Bar systems, by Erik at www.hollowpointmold.com

but I don't have one of those. There are a bazillion to look at on that website though if you click on "example molds".

This is the back of the block.

This is NOE's RG system.

There are also Inset Bar systems, by Erik at www.hollowpointmold.com

but I don't have one of those. There are a bazillion to look at on that website though if you click on "example molds".

Most HP molds have a removable pin from the bottom, some are attached on a slotted bar on the bottom & slides over to remove the bullet These are refered to as RG HPs

Cramers have 2 holes for smaller pins that attach to the HP pin & after opening the pin is pushed from the mold (the 2 smaller pins sliding out of the mold enuff to drop bullet from main pin) . there`s good points for all of em.

I`ve used all 3 & I prefer a SC mold with traditional handle & pin .

The RGs are finicky `bout temp of the alloy & are prone to stik on the pins, but there`s tricks for that.

The 2 cavity cramer I have I have trouble with 1 of the 2 little pins binding when up to temp & it costs time to push it back in place . I`m sure ,if I take time I can tweek it & get it sliding freely.

Most of all it takes time to learn the curve casting HPs , it`s a little different , the 1 thing common with all of em is to keep the pins HOT!!

Here`s a link to Eriks services & he`s a TOP SHELF machinist & a FINE feller to deal with !!!

Check out his pics !!!

http://www.hollowpointmold.com/

GP

Nice pics Beagle 333, they`re worth every bit of typin I did while you posted em

I need to take some pics of mine

Cramers have 2 holes for smaller pins that attach to the HP pin & after opening the pin is pushed from the mold (the 2 smaller pins sliding out of the mold enuff to drop bullet from main pin) . there`s good points for all of em.

I`ve used all 3 & I prefer a SC mold with traditional handle & pin .

The RGs are finicky `bout temp of the alloy & are prone to stik on the pins, but there`s tricks for that.

The 2 cavity cramer I have I have trouble with 1 of the 2 little pins binding when up to temp & it costs time to push it back in place . I`m sure ,if I take time I can tweek it & get it sliding freely.

Most of all it takes time to learn the curve casting HPs , it`s a little different , the 1 thing common with all of em is to keep the pins HOT!!

Here`s a link to Eriks services & he`s a TOP SHELF machinist & a FINE feller to deal with !!!

Check out his pics !!!

http://www.hollowpointmold.com/

GP

Nice pics Beagle 333, they`re worth every bit of typin I did while you posted em

I need to take some pics of mine

Well there ya have it, ^^^ they both got the jump on me while I was clearing out a drain.

I have the single pin like the Lyman Devastator and I also have the MP. I find the MP's MUCH more gratifying to use.

With any of them keeping the pins hot is the key to getting good HP's. The Lyman you have to put the pin in the bottom, then pour then pull then reinsert it after dumping the bullet. WHile it can be done these type molds are usually one cavity and make for slow going if your looking for production.

The Cramer style and variations will allow production if you have everything up to temp. There are things which will get in your way however like the sticking pin on GP100's which will cause you to cut a session short.

On that pin GP is it on a MP mold? If so have you tried loosening both pins up just a touch so they have a little wiggle room? If not you might give that a try, it has worked wonders on a couple of mine that were a bit out of line.

Swampman you also have to have your alloy right as well. If the bullets are high in antimony they will be brittle and shatter, to soft they will blow up. Sort of like the porridge, you want it to be just right. That isn't a huge deal as there are several ways to get where your wanting to be with them. Some use a 10-1, 16-1, 20-1, and so on depending on what they are shooting them out of, the diameter of the cavity, and the velocity that they are shot at. All things that have to be considered rather than just pouring up straight WW's and sizing to fit.

I have the single pin like the Lyman Devastator and I also have the MP. I find the MP's MUCH more gratifying to use.

With any of them keeping the pins hot is the key to getting good HP's. The Lyman you have to put the pin in the bottom, then pour then pull then reinsert it after dumping the bullet. WHile it can be done these type molds are usually one cavity and make for slow going if your looking for production.

The Cramer style and variations will allow production if you have everything up to temp. There are things which will get in your way however like the sticking pin on GP100's which will cause you to cut a session short.

On that pin GP is it on a MP mold? If so have you tried loosening both pins up just a touch so they have a little wiggle room? If not you might give that a try, it has worked wonders on a couple of mine that were a bit out of line.

Swampman you also have to have your alloy right as well. If the bullets are high in antimony they will be brittle and shatter, to soft they will blow up. Sort of like the porridge, you want it to be just right. That isn't a huge deal as there are several ways to get where your wanting to be with them. Some use a 10-1, 16-1, 20-1, and so on depending on what they are shooting them out of, the diameter of the cavity, and the velocity that they are shot at. All things that have to be considered rather than just pouring up straight WW's and sizing to fit.

You got that right, Brother!!The RGs are finicky `bout temp of the alloy & are prone to stik on the pins....

Nice pics Beagle 333, they`re worth every bit of typin I did while you posted em

I heard somewhere that a picture is worth a paragraph.

(Well, ..... it did sit here unanswered for almost 2 hours before I posted em!)

Hey Beagle a the stiky pins round ??? if so polish em with some 600 grit or finer ,then when they get hot just barely touch em with some Bull Shop sprue plate lube , but I mean just a small tad, too much & it`ll blow a hole out in the body of the bullet (they don`t like boolit over here)

Yes , Mike/Tx it`s a MP mold & it never dawned on me to loosen the guide pin , I feel like DUH you meathead !!!

Thanks Mike/Tx !!!

Yes , Mike/Tx it`s a MP mold & it never dawned on me to loosen the guide pin , I feel like DUH you meathead !!!

Thanks Mike/Tx !!!

These are the pins. They are round. I put a little lube on em with a Q-tip and that'll last for a little while. Sooner or later I'll hit the perfect mold temp (accidentally) and they'll start falling without it. Mebbe I should get one of them laser thermometers to shoot the mold with, next time it gets to that temp.