Magnum Wheel Man

New member

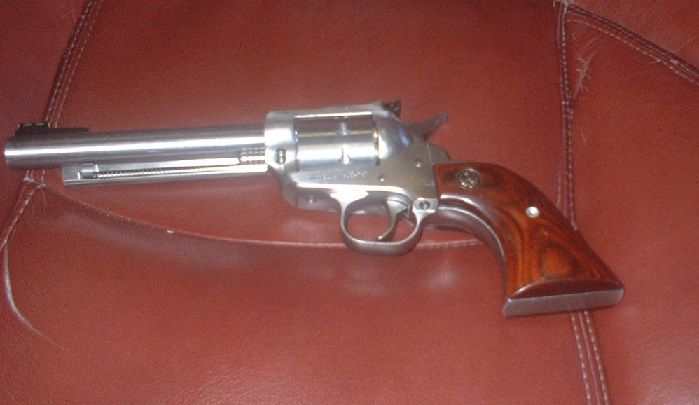

so I have a custom revolver it was built on a stainless Ruger Single 10 that I just couldn't make myself like... I converted it to an 8 shot 257 Special ( centerfire ) when the work was done, carbon steel was used for the barrel & new cylinder, & the finish of the carbon steel in the white, matched the stainless exactly... trouble is, it's not very corrosion resistant in the white, & I'm fighting finger prints & dusting of surface rust...

so to complete, I feel I need to finish the barrel & cylinder at minimum...

I'm wondering if I can nickel plate the barrel & cylinder in some form, that will match the stainless frame, or if I can nickel plate both the carbon steel & stainless to get a matching finish???

also considered blueing the barrel & cylinder & leaving the balance of the gun in stainless ( it's a single action, so the extractor tube is also stainless )

looking for suggestions here... duo color, or one color, & anyone in the know, that could recommend weather the nickel should be able to match the stainless??? & or if I'm assuming correctly, that I could nickel finish the stainless to match the carbon steel parts if they were nickeled at the same time...

the gun... right after it was completed...

Thanks

so to complete, I feel I need to finish the barrel & cylinder at minimum...

I'm wondering if I can nickel plate the barrel & cylinder in some form, that will match the stainless frame, or if I can nickel plate both the carbon steel & stainless to get a matching finish???

also considered blueing the barrel & cylinder & leaving the balance of the gun in stainless ( it's a single action, so the extractor tube is also stainless )

looking for suggestions here... duo color, or one color, & anyone in the know, that could recommend weather the nickel should be able to match the stainless??? & or if I'm assuming correctly, that I could nickel finish the stainless to match the carbon steel parts if they were nickeled at the same time...

the gun... right after it was completed...

Thanks