condor bravo

New member

After filling a number of cases with water up to the neck, what is the procedure for measuring or weighing the water for comparisons? Like pour the water from each case into your scale pan and weigh them??

FWIW, I zero the scale with the dry case then weigh the filled case. Saves doing the math.

I'm sort of thinking that with the case full of water, it might be difficult to balance on a free swinging scale pan and possibly tip over.

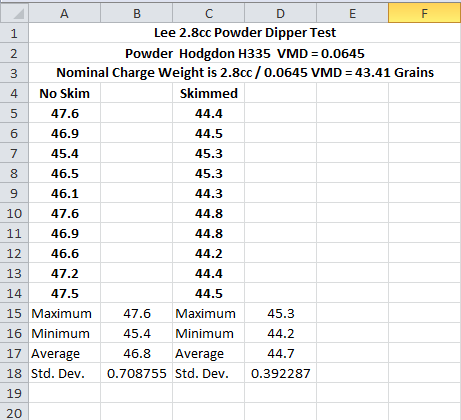

It is very important that you repeat this process with any new container of the same powder because the powder companies allow themselves a 16% tolerance between batches. This can result in over charging if you work from the same setting and the next container of powder you get is more dense.