What weighing does is put the same amount of potential energy in the case each time. What burn rate does is decide how fast that energy is released, thereby determining peak pressure. If you are trying to control peak pressure, velocity, and barrel time, these factors don't always play nicely together in stick powders, but other times do very well.

If the powder burns faster, you need less of it to reach a given pressure. Just look at loads for fast and slow powders to verify this trend. There are exceptions because energy content per grain varies among powder formulations just as bulk density does, but when the fast and slow charges are the same powder, energy content is constant.

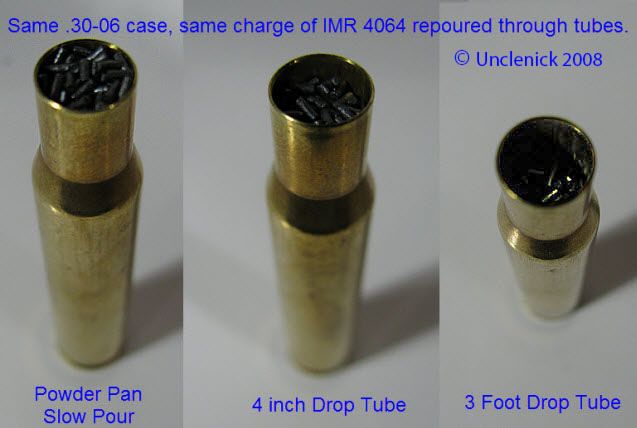

A couple of examples: I think it was the late Dan Hackett who described a stick powder load that worked great when he loaded it at home, but which caused sticky bolt lift when he loaded it at the range to the same charge weight. So he had the same potential energy, it's just that he got this high pressure sign when he loaded it at the range. He cross-checked his equipment and calibration and verified this was true. He finally figured out that the load he put together at home was packing down some due to vibration in his vehicle when he drove it to the range. Same charge weight, same powder, different pressures due to different burn rates due to loose or tight packing.

Stick Powders can pack considerably; spherical propellants not so much.

Another is an oldie but goody from Hatcher. In the late 20's he was selecting a powder for the National Match ammunition for the year. He said he had two powders that had about the same nominal burn rates as the more modern IMR4320 does. One was a short stick powder that the arsenal powder metering equipment could dispense to ±0.30 grains precision. The other was a coarse stick the arsenal equipment could only dispense to ±0.85 grains. Yet, in testing that coarse stick with the sloppy charge, it proved to produce better accuracy than the more precisely metered finer stuff did, so the coarse powder was used that year.

The reason for the better accuracy is going to be the tendency of the coarse powder to self-compensate by changing burn rate with packing density in a way that was better tuned to the .30-06 with 173 grain bullet than the fine powder's compensation was one was. Why? Happenstance. Hatcher said he caught flak from a competitor at the National Matchesho had pulled some of the ammo and found the charge weight variation too great for his liking, and declared the ammo was no good. Several new records were fired with it that year.

So you can see stick powders can self-compensate, but don't necessarily do so in a way that matches your chambering and bullet choice. The chronograph will give you an indication of that. Obviously, just seeing which load shoots more accurately will do that, too (which I failed to mention), but you may need to do a good bit of load work-up shooting at longer ranges to pick it out that way. Hatcher was running 100 round machine rest grouping tests at 600 and 1000 yards.