You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

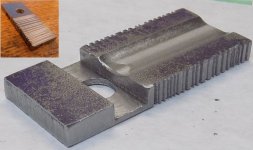

Making Mauser bedding blocks

- Thread starter Clark

- Start date

Yes, they work.

The fastest way for me to test bedding is to grasp the stock wrist in one hand and smack the barrel with the heel of my other hand and then listen. The barrel and stock should resonate like a tuning fork for a second.

The way they work is:

1) The steel bedding block is fastened to the stock with a good area of epoxy.

2) The barreled action from above and the trigger guard from below clamp the steel block.

3) This way a low compliance fastening occurs between the barrelled action and stock mass so that over the recoil time period of 25 ms, they react as one mass.

The barreled action contacts from above via the flat part of the bottom of the recoil lug.

The trigger guard contacts from below via the orifice of the front pillar.

The advantage is that any Mauser barrelled action can drop in and have a perfect fit.

The disadvantage is some commercial Mausers are cast, and the bottom of the recoil lug is crude and rough. I have turned some commercial Mauser actions upside down in the mill and flattened out the bottom of the recoil lug.

I have built this same type of system, but different dimensions, for Mosin Nagants. They vary in the angle of the back of the recoil lug. I mill the back of the recoil lug square. Any Mosin would drop in that has been milled, but I am the only one doing that, so almost none

The fastest way for me to test bedding is to grasp the stock wrist in one hand and smack the barrel with the heel of my other hand and then listen. The barrel and stock should resonate like a tuning fork for a second.

The way they work is:

1) The steel bedding block is fastened to the stock with a good area of epoxy.

2) The barreled action from above and the trigger guard from below clamp the steel block.

3) This way a low compliance fastening occurs between the barrelled action and stock mass so that over the recoil time period of 25 ms, they react as one mass.

The barreled action contacts from above via the flat part of the bottom of the recoil lug.

The trigger guard contacts from below via the orifice of the front pillar.

The advantage is that any Mauser barrelled action can drop in and have a perfect fit.

The disadvantage is some commercial Mausers are cast, and the bottom of the recoil lug is crude and rough. I have turned some commercial Mauser actions upside down in the mill and flattened out the bottom of the recoil lug.

I have built this same type of system, but different dimensions, for Mosin Nagants. They vary in the angle of the back of the recoil lug. I mill the back of the recoil lug square. Any Mosin would drop in that has been milled, but I am the only one doing that, so almost none

Attachments

The issue I see, is parallelism and perpendicularity.

Mill the recoil block on the receiver square and perpendicular (as you mentioned for the MN- I do that as well, some are just ridiculous), up against your receiver block.

It's all about the recoil absorbing block on the receivers (that function as the "lug") being perfectly square and parallel so that the recoil force is doesn't try to push the receiver off to one side or the other, or up or down- and then the entire receiver being bedded so that it cannot move under recoil.

You're the engineer, but I fail to see how metal to metal with the block is better than metal to Devcon. True, you are increasing the area over which the force is distributed but I don't see how that's an issue.

I have often thought about milling out these shallow recoil blocks on both the MN and the Mauser (mill down the MN block so that it's a shallow as the Mauser) so that they're only slightly larger than the action screws- and custom making recoil lugs as on a modern rifle to fit the barrel.

Have a thick. milled lug like on a custom Rem or Savage- with void around the front action screw area so that it no longer functions to absorb recoil and it's all transmitted to the front lug.

Mill the recoil block on the receiver square and perpendicular (as you mentioned for the MN- I do that as well, some are just ridiculous), up against your receiver block.

It's all about the recoil absorbing block on the receivers (that function as the "lug") being perfectly square and parallel so that the recoil force is doesn't try to push the receiver off to one side or the other, or up or down- and then the entire receiver being bedded so that it cannot move under recoil.

You're the engineer, but I fail to see how metal to metal with the block is better than metal to Devcon. True, you are increasing the area over which the force is distributed but I don't see how that's an issue.

I have often thought about milling out these shallow recoil blocks on both the MN and the Mauser (mill down the MN block so that it's a shallow as the Mauser) so that they're only slightly larger than the action screws- and custom making recoil lugs as on a modern rifle to fit the barrel.

Have a thick. milled lug like on a custom Rem or Savage- with void around the front action screw area so that it no longer functions to absorb recoil and it's all transmitted to the front lug.

Tobnpr,

I was just thinking as driving my answer was not complete, on the exact issue you raised.

In that pic I posted there is a castle shaped spacer piece of home made tooling used to clamp the bedding block to the barrelled action during bedding. The block is pre compressed and as the forward action screw is tightened to do that compression, the block is hammered into contact with the back of the lug. After the epoxy sets up the front action screw is removed and the castle washer is punched out of the stock from above.

To check the back of the recoil lug fit before epoxy, I shine a flashlight behind it looking for a crack on either side. The smallest feeler gauge is 0.0015" and this is a huge gap compared to what can be spotted with a flashlight in the crack. The forces are a max of a couple hundred pounds for the first 5 ms of recoil. This is small when trying to compare the fit of steel and Young's modulus vs the fit of epoxy and its Young's modulus. We are going to have deflections less than 0.001" in a ~~0.375" recoil reaction before bullet exit.

In order for every Mauser barrelled action to fit perfectly in the steel bedding block stock:

1) The rifle is pointed upwards when tightening the front action screw.

2) The stock has enough clearance to allow for the rear of the recoil lug not being square with the barrel.

So far I have not had problems with a dozen Mausers of many types. Their recoil lugs can't be perfect, but I have more than the thickness of a dollar bill clearance under and around my barrels.

I put in rear pillars at the same time as the bedding block. In order to accommodate an 1889 Belgian Mauser the hole in the rear pillar would have to be a stadium shape. I have not done that. So not any Mauser will drop in.

I was just thinking as driving my answer was not complete, on the exact issue you raised.

In that pic I posted there is a castle shaped spacer piece of home made tooling used to clamp the bedding block to the barrelled action during bedding. The block is pre compressed and as the forward action screw is tightened to do that compression, the block is hammered into contact with the back of the lug. After the epoxy sets up the front action screw is removed and the castle washer is punched out of the stock from above.

To check the back of the recoil lug fit before epoxy, I shine a flashlight behind it looking for a crack on either side. The smallest feeler gauge is 0.0015" and this is a huge gap compared to what can be spotted with a flashlight in the crack. The forces are a max of a couple hundred pounds for the first 5 ms of recoil. This is small when trying to compare the fit of steel and Young's modulus vs the fit of epoxy and its Young's modulus. We are going to have deflections less than 0.001" in a ~~0.375" recoil reaction before bullet exit.

In order for every Mauser barrelled action to fit perfectly in the steel bedding block stock:

1) The rifle is pointed upwards when tightening the front action screw.

2) The stock has enough clearance to allow for the rear of the recoil lug not being square with the barrel.

So far I have not had problems with a dozen Mausers of many types. Their recoil lugs can't be perfect, but I have more than the thickness of a dollar bill clearance under and around my barrels.

I put in rear pillars at the same time as the bedding block. In order to accommodate an 1889 Belgian Mauser the hole in the rear pillar would have to be a stadium shape. I have not done that. So not any Mauser will drop in.

We used to check bedding of bench rest rifles by clamping onto the barrel just in front of the stock and put a .001 drop indicator on the forearm. Then loosing and tightening the action screws would show rock in the bedding. I believe if my memory is correct we looked for under .002 reading.

I believe he's referring to an improper bedding job where the receiver is stressed during the process and bends/deflects when the action screws are tightened.

I don't use stock screws when bedding, I use surgical tubing because I feel it provides more even force on the action when pressing it into the bedding compound than screws which are point-load.

I don't use stock screws when bedding, I use surgical tubing because I feel it provides more even force on the action when pressing it into the bedding compound than screws which are point-load.

Clark how could a fella get his hands on one of these blocks?

I just bought a Chinese Mauser that is poorly bedded into a Ram line synthetic, all I'm going to do is rebed and shoot it, it came with a nice old Redfield Peep sight system that I can actually see fairly well, chambered in 3006, nice and short.

I just bought a Chinese Mauser that is poorly bedded into a Ram line synthetic, all I'm going to do is rebed and shoot it, it came with a nice old Redfield Peep sight system that I can actually see fairly well, chambered in 3006, nice and short.