You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making guns in the garage

- Thread starter phudd

- Start date

I went to school for the fine art f chip making. The gunsmithery I learned on my own.I assume your not self taught.

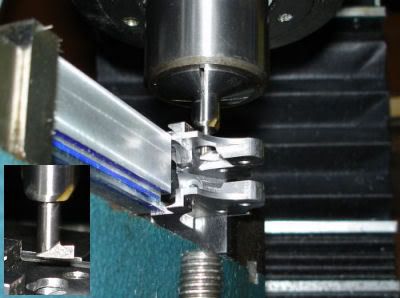

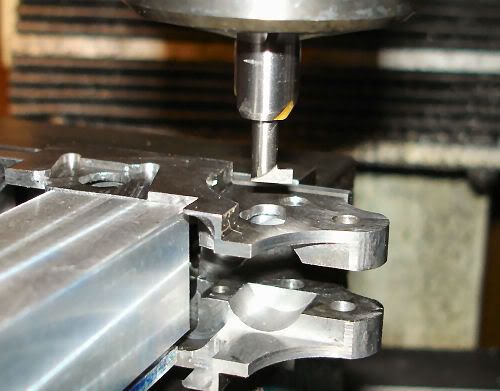

With such a long end mill extension there was really no need. The cuts were quite small.Why not back plate when your milling out the channel for the op-rod spring and its guide? I'd worry about the mill pushing it over.

Hard to say. I worked on them off and on on all manual equipment.How long does it take you to make one?

When I was a little kid, we made firecracker guns with a hacksaw and a drill in the garage.

Now we are old retired men, we make gun parts on our mills and lathes in the garage.

Now we are old retired men, we make gun parts on our mills and lathes in the garage.

Attachments

-

Yuasa rotary table, 3 jaw chuck, and tailstock mounted on mill table to make a cut on 1885 scop.jpg145.4 KB · Views: 49

Yuasa rotary table, 3 jaw chuck, and tailstock mounted on mill table to make a cut on 1885 scop.jpg145.4 KB · Views: 49 -

1885 scope mount cleaned with ultra sound 9-24-2012.jpg80.6 KB · Views: 51

1885 scope mount cleaned with ultra sound 9-24-2012.jpg80.6 KB · Views: 51 -

257 Roberts Ackley improved rimmed 1885 falling block riflt built in Oct 2012 and used b 10-25-2.jpg76.1 KB · Views: 51

257 Roberts Ackley improved rimmed 1885 falling block riflt built in Oct 2012 and used b 10-25-2.jpg76.1 KB · Views: 51

Hunter Customs

New member

Very impressive work, I would say you learned your machining skills very well.

I always wanted to take some machining classes, never had the time, so all my machining is self taught.

Best Regards

Bob Hunter

www.huntercustoms.com

I always wanted to take some machining classes, never had the time, so all my machining is self taught.

Best Regards

Bob Hunter

www.huntercustoms.com

Dixie Gunsmithing

Moderator Emeritus

I noticed something in Clark's photo of the indexing head, that he did correctly, and should be pointed out. Always leave the quill or spindle up, and use the knee to raise the part when milling. I've seen many bring the quill down to meet the part, and an extended quill will cause chatter. Always, keep everything tight and drawn up as close as possible. Use the quill for drilling and tapping only, unless you have to reach inside a cavity, and if so, take lighter cuts. Always lock the quill when milling.

On lathes, you want to do the same thing, especially when parting.

On lathes, you want to do the same thing, especially when parting.

AKs, cuz they are easy

Bending an AMD65 receiver flat on a homemade jig

This is what it looked like when I first built it.

I was never quite happy with it so I made a new brake (Pined & welded), fabricated a new stock and added the magpul grip and AFG. This thing blows a giant fireball.

I still have not duracoated the new bits

A Romy G built on a pre-bent blank. I parkerized the receiver, not too dark but it came out even.

Bending an AMD65 receiver flat on a homemade jig

This is what it looked like when I first built it.

I was never quite happy with it so I made a new brake (Pined & welded), fabricated a new stock and added the magpul grip and AFG. This thing blows a giant fireball.

I still have not duracoated the new bits

A Romy G built on a pre-bent blank. I parkerized the receiver, not too dark but it came out even.

Thanks for sharing!

I'm self-teaching machining...just added a LMS Hi-Torque Mini-Mill and a lathe to start learning the basics. Rigged on an inexpensive DRO to start playing around, thinking about milling me and the boys some lowers from 80%'ers to get started. Then, Mach 3 and CNC conversion...so much to learn in "spare time"of which I have zero...

Now, that's some motivation, with those pics.

I'm self-teaching machining...just added a LMS Hi-Torque Mini-Mill and a lathe to start learning the basics. Rigged on an inexpensive DRO to start playing around, thinking about milling me and the boys some lowers from 80%'ers to get started. Then, Mach 3 and CNC conversion...so much to learn in "spare time"of which I have zero...

Now, that's some motivation, with those pics.

Dixie Gunsmithing

Moderator Emeritus

tobnpr,

DRO's are nice, but I still use a dial indicator and a magnet base for most everything. (I have 1/2" to 3" indicators here). One day, if they'll get the price down for a two or three axis set, then I'll jump on the bandwagon.

They're making those new linear readouts, at a good price, but I'm not sure how accurate they are. Has anyone on here tried them? I thought about buying one for depth measurement on the spindle.

DRO's are nice, but I still use a dial indicator and a magnet base for most everything. (I have 1/2" to 3" indicators here). One day, if they'll get the price down for a two or three axis set, then I'll jump on the bandwagon.

They're making those new linear readouts, at a good price, but I'm not sure how accurate they are. Has anyone on here tried them? I thought about buying one for depth measurement on the spindle.