My advice for reloading for Garands/M1as is to

1. Full length resize in a small base die

2. Trim cases

3. Clean primer pockets, ream to depth

4. Prime all cases by hand, verify that all primers are below the case head, and use the least sensitive primers you can find.

5. Use IMR4895/AA2495/H4895 powders.

6. Seat the bullets to magazine depth, no longer than 3.3” inches for the 30-06, no longer than 2.8 for the 308, shorter is fine.

There are important safety considerations when reloading for Garands, M1as, and M1 Carbines. All of these rifles are functionally similar in that they all have a free floating firing pin. The risk in all mechanisms with free floating firing pins is that incidental contact between the firing pin and primer can cause cartridge ignition, or a “slamfire”. You can search the web and every mechanism with a free floating firing pin has a posted slamfire incident. This includes AK47s, SKSs, French rifles, etc, etc, etc. The worst case slamfire is a slamfire that occurs out of battery, this will result in a catastrophic failure of the mechanism. The Garand mechanism has the most out of battery slamfires of any rifle on the market, and this is due to the lack of a positive mechanical firing pin lock or blocking device. All of the Garand based mechanisms share a firing pin retraction cam, this cam pulls the firing pin back during extraction. It also has limited utility as a safety device, because it blocks to a limited extent the firing pin going forward, but that only happens in the last 0.007” of movement. Long or tight rounds totally defeat the firing pin retraction’s cam ability to hold back the firing before cam down. Given an overly sensitive primer, one that will go off when struck by a rebounding firing pin, if you sized your round smaller than the chamber the odds would will be in your favor to have an in battery slamfire.

Only at final cam down is the firing pin retracted. Up to then the firing pin is totally free floating and tapping the heck out of the primer.

This is a M1 Carbine firing pin retraction cam.

A M1 Garand firing pin retraction cam is functionally identical, just the carbine is easier to visually understand.

Firing pins in this mechanism are free floating and the mechanism does not have a positive mechanical interlock to prevent incidental contact between the free floating firing pin and the primer. As can be seen here, that bolt has around three inches of travel before the firing pin tang touches the retraction cam.

This is a M1 Garand receiver and the firing pin is fully forward and just touching the firing pin retraction cam. As you can see there is only thousand's of an inch of forward movement left in bolt cam down and yet the firing pin is out about 0.064" of the bolt face.

It turns out that cam down is the point at which out of battery slamfires occur. It does make sense that it is because here the bolt has its highest forward velocity and yet, it has to de accelerate to go into battery. The firing pin , of course, has the same velocity of the bolt, but on cam down, being free floating, it continues to move forward and it will rebound off the primer. If the bolt has to stop to crunch fit a long or a fat case that firing pin is rebounding off the back of the primer at its highest velocity and the lugs are not engaged.

That is why it is best practice to small base size cases used in these rifles and to set up the dies with a case gage and size to gage minimum. (Assuming you don’t know the headspace of your chamber, if you do, always be 0.002 to 0.003” less) You want the bolt to close without resistance. This will reduce the risk of an out of battery slamfire assuming an overly sensitive primer. You can still have an inbattery slamfire given an overly sensitive primer, also an undesirable event, but an inbattery slamfire is less likely to blow off the back of your receiver, blow the bolt face off, rip off the elevation knob, and split the stock in two.

If you attempt to small base size with a spray on lube you will stick the case in the die. I recommend RCBS water soluble or Imperial Sizing wax. These are excellent lubes.

For these rifles it is good practice to ensure ream primer pockets to depth, seat the primers by hand, and verify that all of the primers are below the primer pocket. There is a chance that a cocked primer, with the anvil firmly seated on something, could ignite when hit by the bolt fact. Clean those pockets! High primers are one of the most common cause of misfires because the primer won't fire unless the anvil is seated and is pushed up into the primer cake.

http://www.shootingtimes.com/2011/01/04/ammunition_st_mamotaip_200909/ However, given a shallow pocket, given debris in the pocket, it is possible that high a primer could be ignited by the bolt face.

After seating primers examine the back of the case and see if there are high or cocked primers.

It is also safety critical to use the least sensitive primer around because these rifles will slamfire in battery or worse, out of battery, given a sensitive enough primer.

Federal primers are the most sensitive primer on the market and the most "slamfiring" primer in Garands. I have lots of web accounts of slamfires with Federal primers. Don’t use them. I recommend CCI #34s and Tula7.62 primers as they considered "Mil Spec" primers. Which means they are less sensitive than commercial primers, federal are the most sensitive commercial primer on the market

Slamfires are a low probability event, but they do happen. The DTIC document :

Comparison Test of Rifles 7.62 mm, M14, Manufactured by Springfield Armory and Harrington and Richardson Arms Company, July 1963 has the only credible data that can be used in estimating out of battery slamfire probabilities. In this test six new M14’s were undergoing various tests. Each was to be fired 6000 rounds each. One Springfield Arsenal M14 slamfired out of battery at round 5271. Based on this, I estimate that the probability of a slamfire with military spec primers is 1:35,000 per round fired. The slamfire risk with more sensitive commercial primers would be higher.

When firing single shot, use a SLED. Do not put a round in the chamber and drop the bolt. Lots of inbattery slamfires, and a few out of battery, have happened because of this. You want to slow the bolt down. When rounds feed from the clip the friction between cartridges slows the bolt a bit. You want to use a SLED as that slows the bolt a bit.

If loading a Garand without a SLED, lower the bolt about 1” over the follower and let go. Always get your hand out of the way so that if the mechanism slamfires the operating rod does not cut through the palm of your hand.

Use powders that are close to IMR 4895 in burning rate or just use IMR 4895. This mechanism will be over accelerated if gas port pressures are too high. This will happen with powders that are too slow, such as IMR 4350, or loads that are too high pressure. This round pre dates WW2 and was not a magnum round and the commercial round is loaded to pressures higher than the service round. Reference b. recommends choosing powders that have burning rates between IMR3031 and IMR4320. This includes powders such as IMR 4064, and Winchester 748. Accurate Arms stated that AA2520, AA2495 and 2700 are their best powders for the M1 Garands. AA2700 appears to be a slow burning powder, listed as even slower than IMR 4350, but Accurate Arms told me, that because it is a ball powder, the pressure curve has dropped enough that port pressures are not excessive for a Garand. The first lots of AA2700 that Accurate Arms sold were actually surplus WC852 and that powder was used in 30-06 ball ammunition and tested in Garands. I believe the first choice of powders are IMR 4985, H4895, AA2495. In the 30-06. I have used a load of 168 grain Sierra Match, 47.0 grains IMR4895, LC cases, and CCI #34 primers OAL 3.300” for years. I am a consistent winner at club matches with this load. This is a great target load, should be considered a maximum load, does not hurt a thing to cut it a grain or two. The maximum bullet weight to use in these mechanisms would be a 175 grain, I don’t recommend any heavier. National Match ammunition was loaded at 2640 fps with a nominal bullet weight of 173 grains.

In the 308 Garand/M1a the staple was a 168 grain 41.5 grains IMR 4895, LC cases, CCI #34, OAL LT 2.800

If you can’t find CCI #34 or Tula7.62 primers then you have to use primers of commercial sensitivity and the risk of a slamfire increases, but I don’t know how much. I do not recommend Federals in this mechanism, I don’t recommend the new brass colored WLR, CCI 200 seems to have a harder cup than other commercial primers, I have never tried Remington primers, no opinion. I have conducted my own primer tests to see what happened over the chronograph, personally I am a fan of the Russian primers, they shoot very well.

Notice that ball ammunition is not that hot, and neither is Lake City National Match.

M1 Garand BMR Receiver Douglas Barrel 1:10 twist

150 gr FMJBT 1966 Ball

14 Nov 2011 T= 74 ° F

Ave Vel = 2545

Std Dev = 20

ES = 68

Low = 2513

High = 2581

N= 8

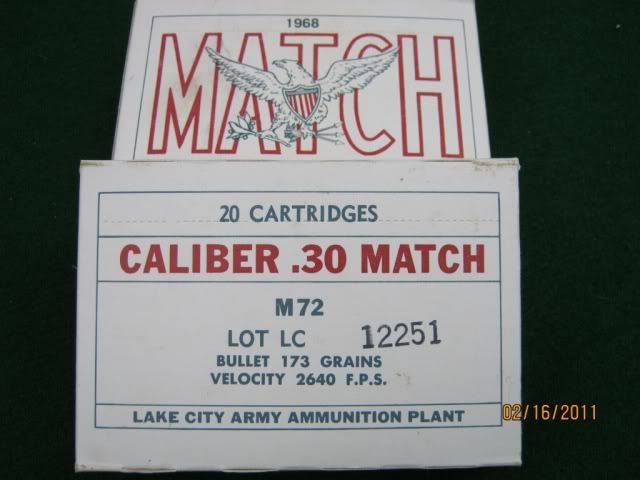

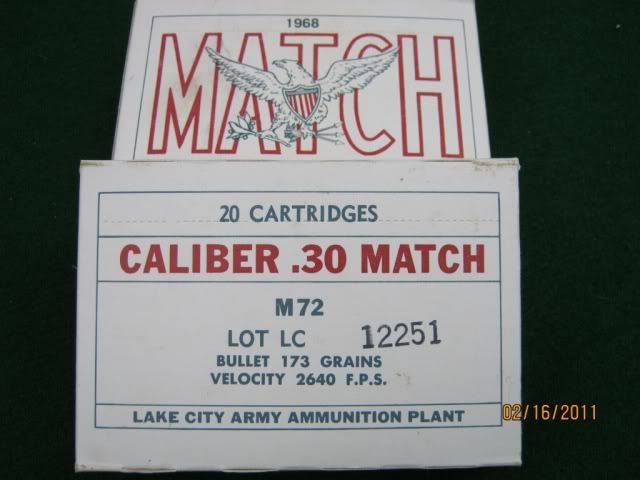

174 FMJBT White Box 1968 NM M72, Headstamp LC67 match, box velocity 2640 fps

14 Nov 2011 T = 74 °F

Ave Vel = 2592

Std Dev = 28

ES = 103

High = 2647

Low = 2544

N = 10

174 FMJBT 47.0 IMR 4895 Lot L7889 thrown LC62NM CCI #34 OAL 3.30

14 Nov 2011 T = 74 °F

Ave Vel = 2632

Std Dev = 20

ES = 60

High = 2671

Low = 2611

N = 10

174 FMJBT 47.0 IMR 4895 Lot L7889 thrown LC62NM Tula 7.62 lot 1-10 primers OAL 3.30

14 Nov 2011 T = 74 °F

Ave Vel = 2582

Std Dev = 15

ES = 49

High = 2602

Low = 2553

N = 10

excellent group

174 FMJBT 47.0 IMR 4895 Lot L7889 thrown LC62NM Wolf NCLR lot 18-09 OAL 3.30

14 Nov 2011 T = 74 °F

Ave Vel = 2607

Std Dev = 17

ES = 57

High = 2642

Low = 2585

N = 10

174 FMJBT 47.0 IMR 4895 Lot L7889 thrown LC62NM WLR (Nickle) OAL 3.30

14 Nov 2011 T = 74 °F

Ave Vel = 2650

Std Dev = 19

ES = 68

High = 2688

Low = 2620

N = 10

Very good group

174 FMJBT 47.0 IMR 4895 Lot L7889 thrown LC62NM CCI200 OAL 3.30

14 Nov 2011 T = 74 °F

Ave Vel = 2599

Std Dev = 22

ES = 75

High = 2637

Low = 2562

N = 10

Very good group

A source for the old NRA recommended loads, for bullet weights other than 168 or 174 can be found here.

http://masterpostemple.bravepages.com/M1load.htm I load my 150’s with 47.5 grains IMR 4895 instead of a max recommendation of 49 grains. I have chronographed and tested all my loads, a 150 SMK with 47.5 grains IMR 4895 is moving just at 2725 fps, and that is as fast as I want a 150 grain bullet to go in this mechanism, regardless of what someone else may say.

Check cartridges for case head separation. Gas guns are hard on brass: the bolt unlocks while there is still significant chamber pressure. Because of this the case gets stretched on extraction. Carefully inspect cases for stretch ring marks at five reloads. They occur about .4” of an inch ahead of the base. You can verify if the cases are internally necking by inserting a bent paperclip in the case, and feeling for an edge.

A number of shooters claim various case lives in the M1 or M1A. Some have case head separations about the fifth reload, others have taken their cases up to ten reloads. The useful lifetime of a case is determined by case head separations, case neck splitting, or primer pocket enlargement. When any one of these failure mechanisms happens to a case, it has exceeded its operational lifetime. In my experience, US military brass holds up better than commercial cases. But this is a broad generalization. You want to use heavy cases over light cases.

References:

a. The Mysterious Slam-Fire, American Rifleman, Oct 1983

b. Reloading for the M1 Rifle, American Rifleman, Mar 1986