Ok, my CRS is getting worse it seems, and I guess I am going to have to start writing things down. Thing with that is I then have to remember where I put the darned notes.

Not sure if it was someone here, or on another forum, but I distinctly remember reading a reply where someone had tied their PID into the heating element on their lubesizer, and gave the temp range they used for Carnuba Red.

For the life of me I cannot remember who, or where it was though. I checked my PM's but didn't see anything related there.

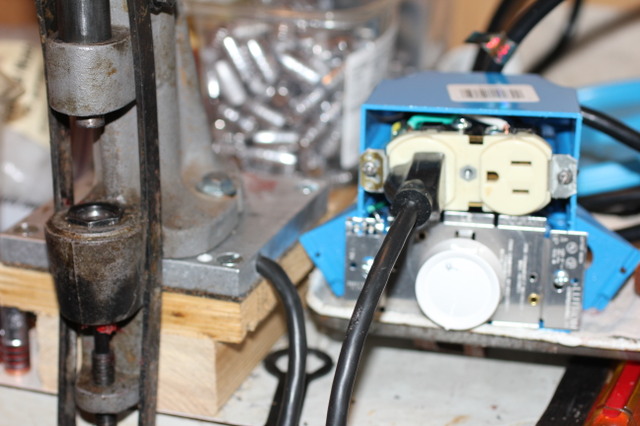

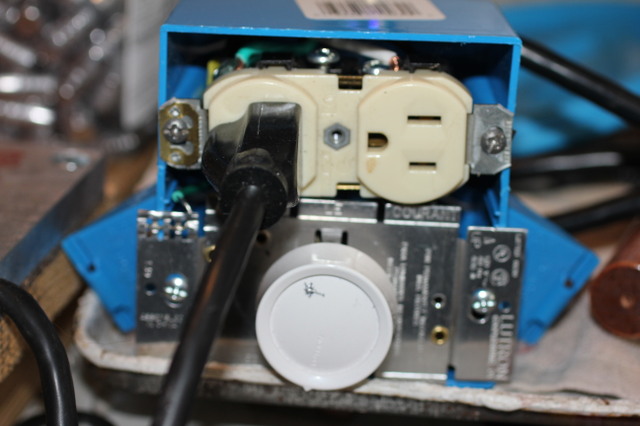

I have it all wired up and ready to go, just need to figure out what temp to run the Carnuba Red at so I can set the PID. Anyone using this set up?

I've never used this thing before, (lubesizer) and had wanted to be done with a few hundred bullets by now and possibly even shot some. I spent yesterday getting it all mounted up in a somewhat portable fashion so I can store it later on. After that I grabbed up my bag of CR, still unopened, and realized these sticks need a hole in them. So I spent the rest of the afternoon building a mold stand so I could remelt, and re pour the lube up this morning, and have 4 sticks ready and waiting.

Got that done then had to unwire my PID from the thermocouple stuck in the lead and add on a terminal strip to enable switching between the Lee pot and the Lyman sizer.

Now then I am fixing to get busy on some bullets and see if I can manage to squeeze some lube in them.

If you have a temp recommendation shoot it to me.

Not sure if it was someone here, or on another forum, but I distinctly remember reading a reply where someone had tied their PID into the heating element on their lubesizer, and gave the temp range they used for Carnuba Red.

For the life of me I cannot remember who, or where it was though. I checked my PM's but didn't see anything related there.

I have it all wired up and ready to go, just need to figure out what temp to run the Carnuba Red at so I can set the PID. Anyone using this set up?

I've never used this thing before, (lubesizer) and had wanted to be done with a few hundred bullets by now and possibly even shot some. I spent yesterday getting it all mounted up in a somewhat portable fashion so I can store it later on. After that I grabbed up my bag of CR, still unopened, and realized these sticks need a hole in them. So I spent the rest of the afternoon building a mold stand so I could remelt, and re pour the lube up this morning, and have 4 sticks ready and waiting.

Got that done then had to unwire my PID from the thermocouple stuck in the lead and add on a terminal strip to enable switching between the Lee pot and the Lyman sizer.

Now then I am fixing to get busy on some bullets and see if I can manage to squeeze some lube in them.

If you have a temp recommendation shoot it to me.

Last edited: