You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lead casting furnace

- Thread starter Plaz

- Start date

I spray mine down with a lite coat of oil if its going to be stored a while. But store in a Dry area that you don’t have a lot of temperature change. A lot of guys use it, but Marvelux flux will rust a pot as fast as if you use salt on it. I tried it once, And went back to the old stand by. Bees wax, Saw dust, or even a little motor oil. All those will smoke pretty good but don’t promote rust. And flux just as well.

DiscoRacing

New member

I have a top pour and a bottom pour.. and they both sit beside one another all the time on my casting bench... no prep/storage needs required.

Disco Racing QUOTE: I have a top pour and a bottom pour.. and they both sit beside one another all the time on my casting bench... no prep/storage needs required.

QUESTION #1: Can you explain this please? I don't know what you mean by top pour and bottom pour.

QUESTION #2: Is your casting bench indoors or outdoors?

QUESTION #1: Can you explain this please? I don't know what you mean by top pour and bottom pour.

QUESTION #2: Is your casting bench indoors or outdoors?

DiscoRacing

New member

the top pour is constructed as a cast pot..with heating element affixed underneath...and you pour it from the top sides.... the bottom pour is a mounted pot...affixed to a bracket that holds it aprox 4 inches off the surface...the heating element is all around the pot enclosed...and there is a lever one pulls that allows the heated lead to pour thru a spicket on the bottom of the pot.... both are on a bench... in an enclosed outbuilding.. that I use as a reloading shop.

DiscoRacing

New member

no

Plaz I think you are talking about a Lee bottom pour pot. I have used them for 30 years. And for the money compared to Lyman and RCBS prices you can’t beat them. They can be finicky. The biggest problem is Dirt or slag in the spout. I have found if you don’t run all the metal out. This will help keep the spout clean. I leave about an inch of lead in the pot. I only put clean pigs in the pot. But you will still get a little trash in. And it will not take much to mess the spout up. Leaving a little lead in the pot. The garbage will stay on top. And out of the spout. And it helps heat up time. Spraying the pot down to store . that’s up to you. The pot is metal. And heating and cooling promotes rust. Type of flux also will. As well as humidity. The oil will just burn off nest time you fire it up.

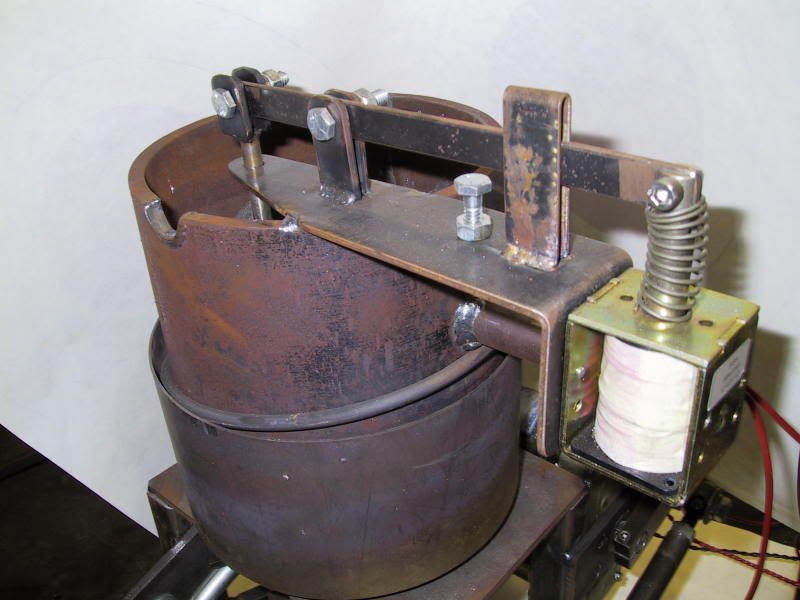

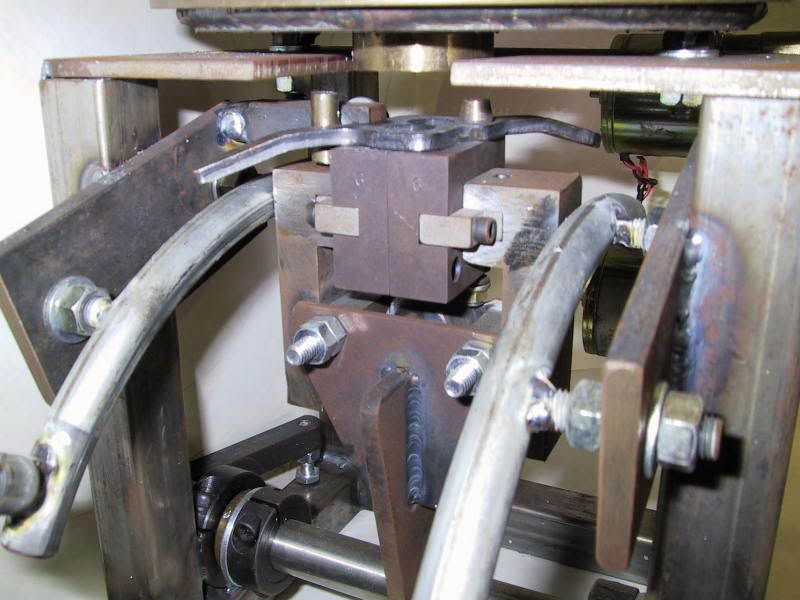

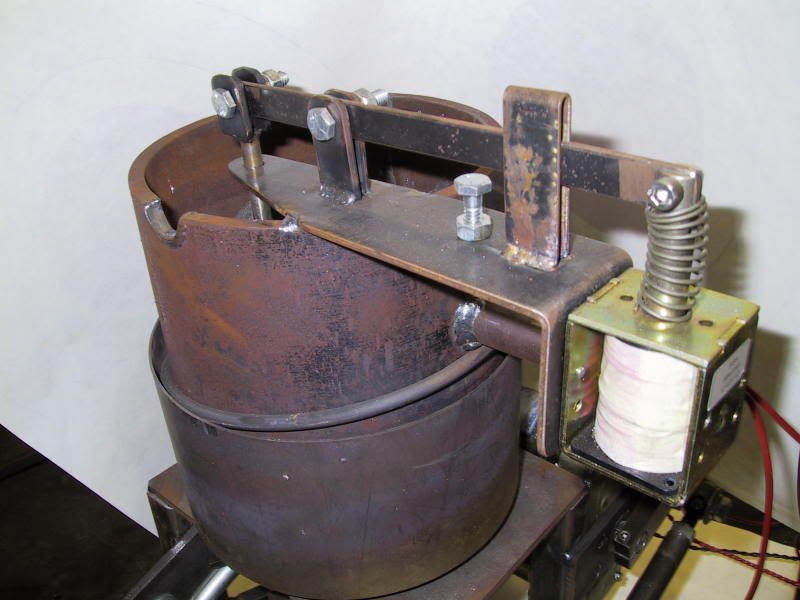

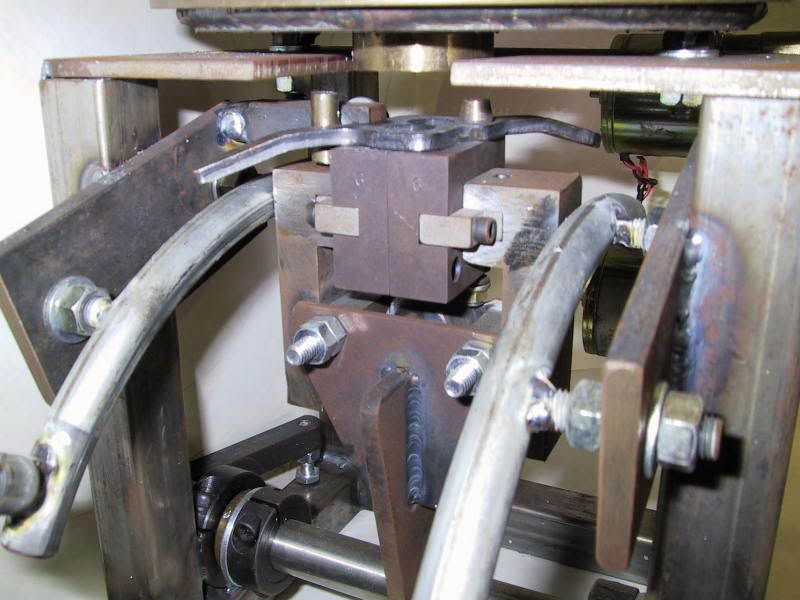

I built a bottom pour machine that holds just over 60#'s I find its best when I'm finished and everything is still hot to get it ready for the next session by filling it up and letting the lead melt down and then flux.

I still flux again before the next session but having the machine already full of lead makes it reheat faster (no air gaps).

One thing with a bottom pour (at least mine) at it tends to dribble while the lead is becoming molten. From initial start up to being ready to cast you might have a pile of lead as big as the size of four quarters come out so I put a little aluminum cup under the nozzles until I’m ready to start.

I still flux again before the next session but having the machine already full of lead makes it reheat faster (no air gaps).

One thing with a bottom pour (at least mine) at it tends to dribble while the lead is becoming molten. From initial start up to being ready to cast you might have a pile of lead as big as the size of four quarters come out so I put a little aluminum cup under the nozzles until I’m ready to start.

Here's a pic of two of my pots, both from lee. The one on the left is a pro 20 bottom pour. The small one on the right is a ladle pot, no means to pour from the bottom, or what disco calls a top pour. I never tried pouring lead from it, always used a ladle.

As far as how I store them, I simply leave what lead I was using in them, turn them off. They sit until I need them again, may be as long as a month before using again. Never had any trouble with rust on any of them,(I have 6 all together).

I originally took the pic to show the mold guide I had made for the pro-20. I was unable to get the supplied guide to work. This one lined the sprue plate holes up perfectly, allowing you to slide the mold under the spout.

As far as how I store them, I simply leave what lead I was using in them, turn them off. They sit until I need them again, may be as long as a month before using again. Never had any trouble with rust on any of them,(I have 6 all together).

I originally took the pic to show the mold guide I had made for the pro-20. I was unable to get the supplied guide to work. This one lined the sprue plate holes up perfectly, allowing you to slide the mold under the spout.

Snuffy I think Lee could stop putting That junk Mold guide in with the 20 pound pot. I redid mine with a piece of one inch Aluminum square stock And u-clamps. So I can adjust for different molds. I saw one on – Line the guy had flat rocks sitting in the bottom to hold the mold. So I guess I’m not the only one that could not get that thing to work Right.

It looks good. I did basically the same thing. But I ran the square stock between the two Post and fastened it with the u-bolts. And welded the Aluminum Guides to the cross member to guide the mold. I have a wedge I slid under the mold guide. Get the distance right. Tighten down the u-bolts. And its good to go. I use the Lyman 4 cavity molds.

IllinoisCoyoteHunter

New member

Snuffy, I like your mold guide, but what happens when your pot begins to drip? After all, it is a Lee. Have you thought about cutting a hole in the guide to line up with the spout so the drips fall through the guide and onto the baseplate?

ICH, mine doesn't drip much. Not kidding. If it starts, I just give the valve stem a twist, it stops. The only flaw is the countersunk screw heads in the oak, if I over-fill the sprue plate, some lead gets in those screw holes/heads. It's a PITA to get out!

I may cover those with some roofing valley aluminum sheeting. Then the lead would just slide off the back!

I may cover those with some roofing valley aluminum sheeting. Then the lead would just slide off the back!

Crusty Deary Ol'Coot

New member

WOW Jmorris!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

I've said for years that I can out cast any bottom pour pot I had ever seen or operated.

WOW, not sure that is true after seeing yours!!!!!!

WOW!

One of the problems with most bottom pour pots is the size. That doesn't seem to be as much of a problem with yours.

With my good sized pot, and a good heat source, I can dump my sprews back into the pot every few minutes, plus add one or two 3lb bars of WW probably every ten minutes or so.

With the pot size and stove - 55 +++ year old Colman gas stove - I am using, I can keep enough heat on the pot to melt the sprews and bars while still casting, using the cool metal to help regulate my alloy temp.

That with the use of a Rowell Bottom Pour Ladle from Advance Car Mover co. is just flat fast.

A friend and I had 2 casting sessions this past week and produced over a 100lbs of product.

I like to cast with a partner, as with one person pouring and the other opening molds and dropping the bullets into our quenching bucket we can really run a lot of bullets.

The friend was new to casting so during our first session he started out a bit slow, but during the second session I had to hump to keep up with him.

We were running 5 molds and might need more if the weather had been warmer.

Check out the Rowell Bottom Pour Ladle, for pot casting it is far and away better then any ladle I have ever used before.

Keep em coming!

Crusty Deary Ol Coot

I've said for years that I can out cast any bottom pour pot I had ever seen or operated.

WOW, not sure that is true after seeing yours!!!!!!

WOW!

One of the problems with most bottom pour pots is the size. That doesn't seem to be as much of a problem with yours.

With my good sized pot, and a good heat source, I can dump my sprews back into the pot every few minutes, plus add one or two 3lb bars of WW probably every ten minutes or so.

With the pot size and stove - 55 +++ year old Colman gas stove - I am using, I can keep enough heat on the pot to melt the sprews and bars while still casting, using the cool metal to help regulate my alloy temp.

That with the use of a Rowell Bottom Pour Ladle from Advance Car Mover co. is just flat fast.

A friend and I had 2 casting sessions this past week and produced over a 100lbs of product.

I like to cast with a partner, as with one person pouring and the other opening molds and dropping the bullets into our quenching bucket we can really run a lot of bullets.

The friend was new to casting so during our first session he started out a bit slow, but during the second session I had to hump to keep up with him.

We were running 5 molds and might need more if the weather had been warmer.

Check out the Rowell Bottom Pour Ladle, for pot casting it is far and away better then any ladle I have ever used before.

Keep em coming!

Crusty Deary Ol Coot