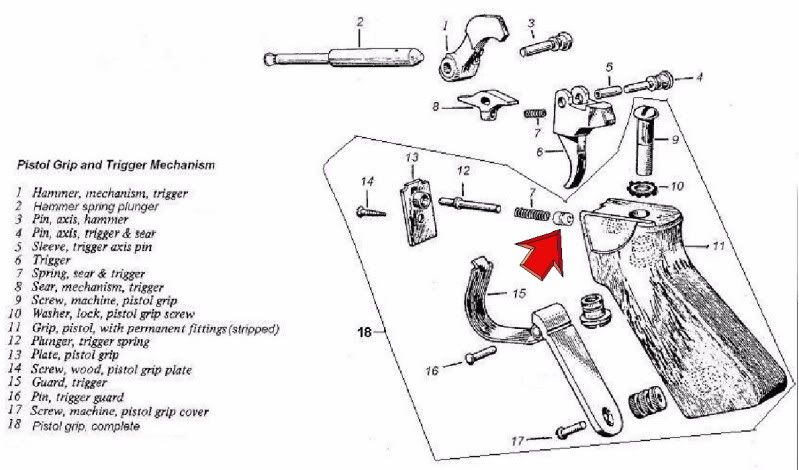

I have just bought a Lithgow L1A1 SLR ex NZ Army which I have not yet fired (need some dies to reload for it). I am not hat familiar with this rifle but it appears to have a "safety" on the trigger in addition to the normal safety lever on the side. After the rifle is cocked, safety off, it will not fire (dry fire) until the trigger is pushed forward a couple of mm. Then it is fine. It seems to be almost a definite click.

Is this a "quiet safety" for bush work or is there a weak or broken spring or something in the trigger mechanism? The rifle itself looks clean and well looked after.

I have searched the internet but can find no reference to this. An ex-army friend who remembers the SLR in service says he cannot recall such a mechanism which makes me think it might be a defect.

Any enlightenment would be appreciated before I actually fire it.

Thanks

David

Is this a "quiet safety" for bush work or is there a weak or broken spring or something in the trigger mechanism? The rifle itself looks clean and well looked after.

I have searched the internet but can find no reference to this. An ex-army friend who remembers the SLR in service says he cannot recall such a mechanism which makes me think it might be a defect.

Any enlightenment would be appreciated before I actually fire it.

Thanks

David