Bytesniffer

New member

I bought another digital gauge

To verify my readings

My new hornady gauge

Read cartridge length

1 thousandth to 1.5 thousandths

Smaller then my ez calc I've

Had for 6 months.

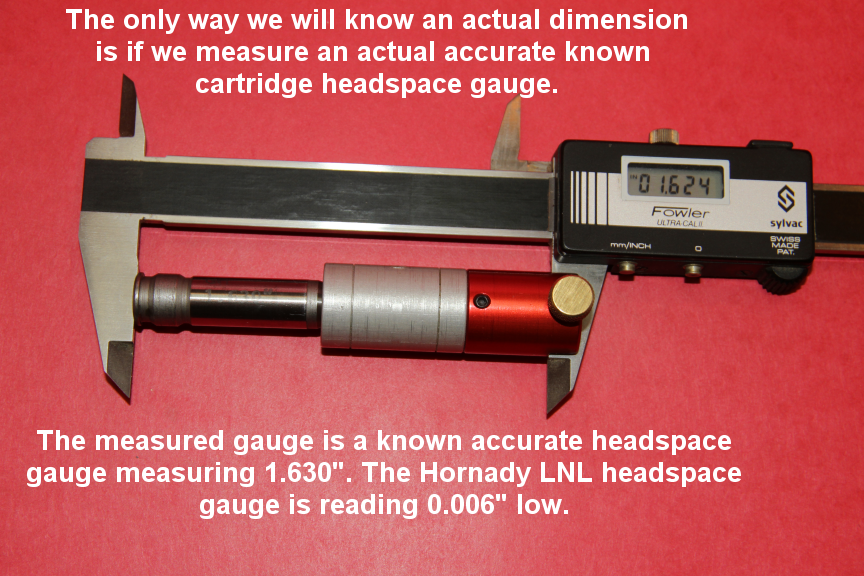

Head space gauge with hormady caliper reads

Almost 5 thousandths smaller

Which ones right ?

To verify my readings

My new hornady gauge

Read cartridge length

1 thousandth to 1.5 thousandths

Smaller then my ez calc I've

Had for 6 months.

Head space gauge with hormady caliper reads

Almost 5 thousandths smaller

Which ones right ?

Last edited: