Come back from the range yesterday and had 52 rounds of 7 mag brass that I had fls last week. Was factory ammo and it's being loaded by me for 3rd time. Set down to trim with Lee trimmer and drill chuck. Nothing coming off first 2 pieces. Measured ever piece and they are either right on 2.50 as Nosler states or running 2.492 and up. 90 % at 2.50. Wilson case guage shows all lengths as perfect or still above any danger on the check grooves. Been running 60 to 62 grains of IMR 4031 under 140-150 nbts. Low to mid range loads. Is this why they aren't stretching or am I wrong about something. Remington and Federal Brass. Both the same.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Isn't brass supposed to stretch after firing

- Thread starter Wendyj

- Start date

jwrowland77

New member

Most the time it will stretch after FL resizing.

If you're neck sizing, then very little if any will get trimmed off.

Make sure to do your trimming AFTER resizing.

If you're neck sizing, then very little if any will get trimmed off.

Make sure to do your trimming AFTER resizing.

At the nanno second of detonation the brass swells sealing chamber, but after bullet leaves barrel it retracts to original shape, or not much different.

When you full length size, the brass flows toward neck thus the necessity to trim afterwards.

I like to keep all the brass from a lot at equal lengths, and when I trim, every 7mm rem mag is trimmed to 2.40, then I can skip trimming that lot for a couple of sizings....not that Im lazy......just frugal with my time.

When you full length size, the brass flows toward neck thus the necessity to trim afterwards.

I like to keep all the brass from a lot at equal lengths, and when I trim, every 7mm rem mag is trimmed to 2.40, then I can skip trimming that lot for a couple of sizings....not that Im lazy......just frugal with my time.

I don't neck size as I haven't ordered dies yet. I'm full length sizing everything we reload. Lee trimmer in chuck won't trim lower than 2.50. I have a trimmer that goes in the press but I can't figure it out at all. Would be handy to save fingers trimming. Only die I have for it is 308 right now. I don't know if it makes any difference but I separate my brass and only use same brand for each load.

I'm no casing expansion expert but I can tell you that prior to me using fire formed casings in my chambers I experienced quit a bit of consistent stretch. Now that I use my FF casings and only push the necks back about .003 for my headspace clearence I get very minimal stretch.

When I got the Wilson guage I fired a round of factory ammo. Set the guage to its dimensions per instructions. With this method I'm not setting shoulders back far at all. Maybe 1/8 extra turn on Lee sizing die. All is shooting ok. I just bought 100 cases of Hornady brass and they seem thinner or something. They fall all the way to bottom of case guage. After sizing they will all need trimmed. It doesn't say if they were once fired brass or not. I would hope after loading and shooting they swell up a little. Is that normal.

I went through 300 7 Remington Magnum cases fired in a rifle I do not own. Everyone of the cases required .020" + trimming to get the cases down to 2.250" before sizing.

After trimming and sizing I checked the cases in the barrel for case head protrusion. I used a case friendly raw hide hammer to bump the cases just in case the case did not make it to the shoulder or the belt seated.

Yes, "I BUMPED" I did not tap the case. I sorted the cases by case head protrusion, the case either seated on the belt, or it seated on the shoulder of the chamber. And then I assembled the rifle, I installed the barrel. I used a box of Hornady molly coated Magnum + Magnum ammo to determine if the new factory over the counter ammo would allow the bolt to close (without extractor, without firing pin).

I then moved to the sorted cases that protruded the least, Half of the cases would chamber and allow the bolt to fall with the weight of the bolt handle. I then moved to the cases that would allow the bolt to close with effort. I screwed the die down to increase the presses ability to overcome the cases ability to resist sizing.

Out of the 300 cases I settled on 140.

On the cases that required effort closing the bolt none require a push from a cleaning rod. The cases fell out of the chamber when the rifle was elevated at the muzzle.

Meaning: When the bolt closed with effort the resistance was coming from the case compressing between the shoulder and the belt face.

I loaded 140 rounds for the rifle, the range is closed, so is the road that runs in front of the range. I will not be there when the range opens, I have nothing against crowds, it is a choice, I avoid them.

After trimming and sizing I checked the cases in the barrel for case head protrusion. I used a case friendly raw hide hammer to bump the cases just in case the case did not make it to the shoulder or the belt seated.

Yes, "I BUMPED" I did not tap the case. I sorted the cases by case head protrusion, the case either seated on the belt, or it seated on the shoulder of the chamber. And then I assembled the rifle, I installed the barrel. I used a box of Hornady molly coated Magnum + Magnum ammo to determine if the new factory over the counter ammo would allow the bolt to close (without extractor, without firing pin).

I then moved to the sorted cases that protruded the least, Half of the cases would chamber and allow the bolt to fall with the weight of the bolt handle. I then moved to the cases that would allow the bolt to close with effort. I screwed the die down to increase the presses ability to overcome the cases ability to resist sizing.

Out of the 300 cases I settled on 140.

On the cases that required effort closing the bolt none require a push from a cleaning rod. The cases fell out of the chamber when the rifle was elevated at the muzzle.

Meaning: When the bolt closed with effort the resistance was coming from the case compressing between the shoulder and the belt face.

I loaded 140 rounds for the rifle, the range is closed, so is the road that runs in front of the range. I will not be there when the range opens, I have nothing against crowds, it is a choice, I avoid them.

Any idea of how many loads you can get out of belted magnum. After inspecting thoroughly I see no signs of any weakness.

This is one of those "it depends" answers.

If you keep to low end loads and a bolt action rifle, I'm guessing the brass could easily last 10 reloads without any issues.

Start loading hot for a semi auto, brass life goes down.

Jimro

The answer depends on headspace and setback. Stretching under pressure for a rimless bottleneck case occurs where the case head meets the side wall. This happens because the pressure is high enough (30-40Kpsi) to stick the case body to the sides of the chamber, and the head is too thick to expand, and the brass isn't strong enough to keep the head from being pushed back against the bolt face, so the only way for that to happen is stretch in that area where the sides of the case meet the head. It also winds up widest in that area, which is called the pressure ring.

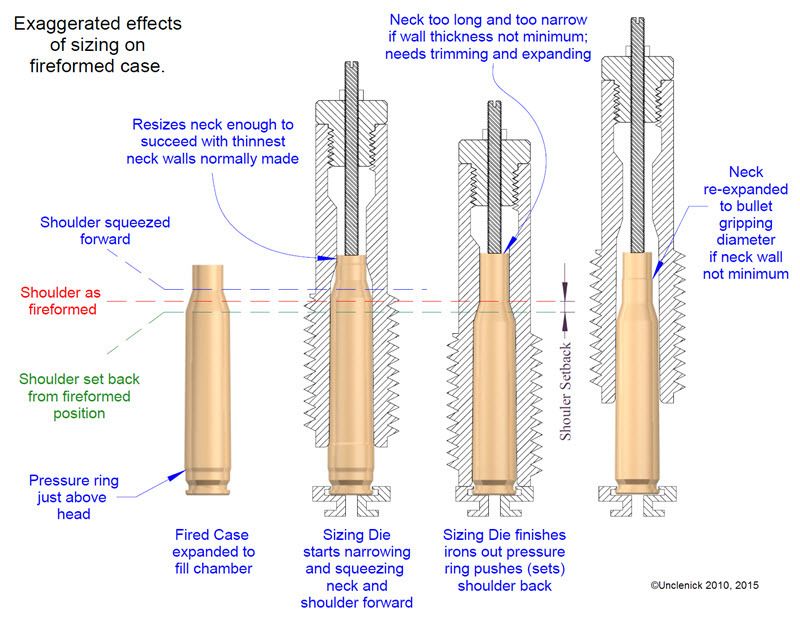

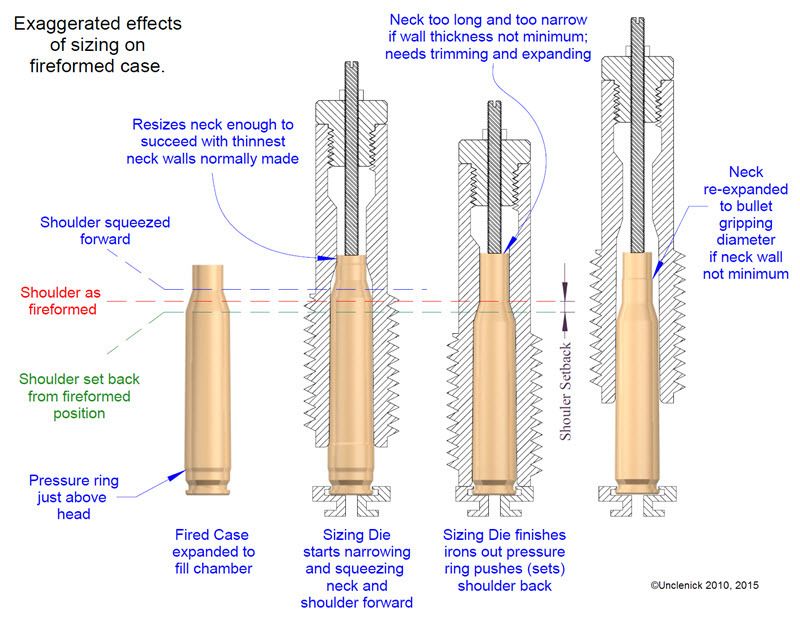

When you resize the case, the stretched pressure ring holds the shoulder forward of its pre-fired position, making the head-to-shoulder dimension longer. When the sizing die pushes the shoulder back, the stretched area withstands than, so the brass flows from the sides to the shoulder, and from the shoulder up into the neck. That lengthens the neck, but the brass doesn't turn the corner from the shoulder to the neck with complete grace, so you get an internal donut ring forming, that shows in the drawing above.

An exaggerated view of the sizing process and its effect on neck length looks like this:

The shooter then trims the case neck back. If he has enough rounds through it to make the donut bad, he can ream the inside of the neck to cut it away. That is important if the bearing surface of your bullet seats down past that donut, at which point it can cause a constriction. Some cartridges with long necks, like 30-06, see most bullet seat shallower than that, so the donut doesn't interfere with seating. Where it does interfere, it raises pressure.

Your belted magnum is a horse of a different color. It headspaces on the belt, so the firing pin can't drive the shoulder of the case into the chamber shoulder unless you size the shoulder to have tighter fit than there is headspace clearance with the belt is driven against the headspace seat. So, normally, the case goes to the belt seat, then any extra space between the case and chamber shoulders is filled by the case shoulder blowing forward. That can actually shorten the neck because the expanding force adds material to the shoulder by taking it from the neck. So even if your head is eventually stretching back, when you resize you are mostly just returning the neck to original length, rather than increasing it. That can change if the particular case has the belt at the lower end of spec, or if your chamber headspace is at the longer end of spec. You can then get a pressure ring stretch in front of the belt and some overall lengthening of the case. But if you have a brand of case whose belt fits your headspace well, you may see little real growth. Watch out for a different case headstamp stretch more.

If you only set the shoulder back a couple thousandths (turn the seating die in about 1/25 of a turn past solid contact with the as-fired shoulder, giving you 0.003" push down, and allowing 0.001" springback), then you can end up headspacing on the case shoulder before the belt finds the bottom of the headspace allowed for it. In that instance the brass will stretch so little that if you anneal the necks and shoulder periodically, and don't hotrod it, there is no good reason not to see the kind of life rimless cases get under those circumstances. Perhaps up to 50 reloads in some instances, but 20 is more common. But if you run them hot, the primer pockets can stretch and stop holding primers before you get there.

Below is a page of scales. Print it. Cut one out and wet it with oil or put some spray-on adhesive on it and stick it to the top of your lock nut. Put a registration mark on your die, and each graduation will represents 0.001" change (with a tiny error that accumulates to half a thousandth in one full turn due to a full turn of 14 tpi threads not producing an even number of thousandths, but it's close enough). Note that because the lock nut changes the scale position when you unscrew it, you just have to unscrew it enough to let you turn the die, then make your adjustment relative to whatever mark lines up with the registration mark you put on the die while you hold the nut to keep it from turning with the die.

When you resize the case, the stretched pressure ring holds the shoulder forward of its pre-fired position, making the head-to-shoulder dimension longer. When the sizing die pushes the shoulder back, the stretched area withstands than, so the brass flows from the sides to the shoulder, and from the shoulder up into the neck. That lengthens the neck, but the brass doesn't turn the corner from the shoulder to the neck with complete grace, so you get an internal donut ring forming, that shows in the drawing above.

An exaggerated view of the sizing process and its effect on neck length looks like this:

The shooter then trims the case neck back. If he has enough rounds through it to make the donut bad, he can ream the inside of the neck to cut it away. That is important if the bearing surface of your bullet seats down past that donut, at which point it can cause a constriction. Some cartridges with long necks, like 30-06, see most bullet seat shallower than that, so the donut doesn't interfere with seating. Where it does interfere, it raises pressure.

Your belted magnum is a horse of a different color. It headspaces on the belt, so the firing pin can't drive the shoulder of the case into the chamber shoulder unless you size the shoulder to have tighter fit than there is headspace clearance with the belt is driven against the headspace seat. So, normally, the case goes to the belt seat, then any extra space between the case and chamber shoulders is filled by the case shoulder blowing forward. That can actually shorten the neck because the expanding force adds material to the shoulder by taking it from the neck. So even if your head is eventually stretching back, when you resize you are mostly just returning the neck to original length, rather than increasing it. That can change if the particular case has the belt at the lower end of spec, or if your chamber headspace is at the longer end of spec. You can then get a pressure ring stretch in front of the belt and some overall lengthening of the case. But if you have a brand of case whose belt fits your headspace well, you may see little real growth. Watch out for a different case headstamp stretch more.

If you only set the shoulder back a couple thousandths (turn the seating die in about 1/25 of a turn past solid contact with the as-fired shoulder, giving you 0.003" push down, and allowing 0.001" springback), then you can end up headspacing on the case shoulder before the belt finds the bottom of the headspace allowed for it. In that instance the brass will stretch so little that if you anneal the necks and shoulder periodically, and don't hotrod it, there is no good reason not to see the kind of life rimless cases get under those circumstances. Perhaps up to 50 reloads in some instances, but 20 is more common. But if you run them hot, the primer pockets can stretch and stop holding primers before you get there.

Below is a page of scales. Print it. Cut one out and wet it with oil or put some spray-on adhesive on it and stick it to the top of your lock nut. Put a registration mark on your die, and each graduation will represents 0.001" change (with a tiny error that accumulates to half a thousandth in one full turn due to a full turn of 14 tpi threads not producing an even number of thousandths, but it's close enough). Note that because the lock nut changes the scale position when you unscrew it, you just have to unscrew it enough to let you turn the die, then make your adjustment relative to whatever mark lines up with the registration mark you put on the die while you hold the nut to keep it from turning with the die.

Most brass stretches the most on it's first firing. Has nothing to do with headspace or setback. Also isn't something to worry about. You check the case lengths every time, but you only trim if it's needed. If it's not over the max OAL forget about it.

Case life depends entirely on the load used. And nothing else.

Case life depends entirely on the load used. And nothing else.

Isn't brass supposed to stretch after firing?

No, it is believed the case stretches when fired.

wendyJ, again, I will risk provoking some members on this forum, provoke to think or just provoke.

Many times I have said I have had cases shorten as much as .035" from beginning to end when forming, sizing and firing cases. Most Internet reloaders do not understand I am talking about the case length from the end of the neck to the case head. I have recommended reloaders measure their cases before firing and again after. WHY?

My cases shorten in length, problem, I have two lengths, I know, it is not fair. My cases do not have head space but my cases do have a length that is measured from the datum/shoulder to the case head. My cases shorten in length but lengthen from the shoulder/datum to the case head, AND! that is the case shortens from the case mouth to the case head. It is not easy to keep up with two thoughts at the same time, provoking someone to think is even more difficult.

Many times I have ask the question about stretch and flow, either or, or is it both? And, always I have a reason for asking.

The Wilson case gage, not the Wilson head space gage.

The Wilson case gage is a datum based tool. It measures from the datum to the end of the case mouth, The Wilson case gage also measures the case length from the datum to the case head.

Back to the big inning, I suggested a reloader measure the case length before firing and after firing. You have a Wilson case gage, you could have measured the case length from the before firing, problem, you did not measure the length of the case from the shoulder of the case to the case head, THEREFORE! I am the only reloader responding to you question that understands your case lengthened from the shoulder to the case head and shortened from the shoulder to the case mouth.

Your case shortend in length from the mouth of the case to the case head because your case body filled the chamber. When the case filled the chamber you formed a new shoulder. Meaning part if your old shoulder became part of the case body and part of the neck became part of the case shoulder.

to accomplish all of that the neck is pulled back because the belt of the case has the case pinned to the rear.

Again, I have cases that shorten .035", there are times I form cases that shorten .035" when forming before firing. What is a reloader to do? I ask. I look for long cases, my favorite cases are long cases, problem. manufacturers of cases do not sell long cases for reloaders that know what they are doing.

F. Guffey

No, it is believed the case stretches when fired.

wendyJ, again, I will risk provoking some members on this forum, provoke to think or just provoke.

Many times I have said I have had cases shorten as much as .035" from beginning to end when forming, sizing and firing cases. Most Internet reloaders do not understand I am talking about the case length from the end of the neck to the case head. I have recommended reloaders measure their cases before firing and again after. WHY?

My cases shorten in length, problem, I have two lengths, I know, it is not fair. My cases do not have head space but my cases do have a length that is measured from the datum/shoulder to the case head. My cases shorten in length but lengthen from the shoulder/datum to the case head, AND! that is the case shortens from the case mouth to the case head. It is not easy to keep up with two thoughts at the same time, provoking someone to think is even more difficult.

Many times I have ask the question about stretch and flow, either or, or is it both? And, always I have a reason for asking.

The Wilson case gage, not the Wilson head space gage.

Wilson case guage shows all lengths as perfect or still above any danger on the check grooves

The Wilson case gage is a datum based tool. It measures from the datum to the end of the case mouth, The Wilson case gage also measures the case length from the datum to the case head.

Back to the big inning, I suggested a reloader measure the case length before firing and after firing. You have a Wilson case gage, you could have measured the case length from the before firing, problem, you did not measure the length of the case from the shoulder of the case to the case head, THEREFORE! I am the only reloader responding to you question that understands your case lengthened from the shoulder to the case head and shortened from the shoulder to the case mouth.

Your case shortend in length from the mouth of the case to the case head because your case body filled the chamber. When the case filled the chamber you formed a new shoulder. Meaning part if your old shoulder became part of the case body and part of the neck became part of the case shoulder.

to accomplish all of that the neck is pulled back because the belt of the case has the case pinned to the rear.

Again, I have cases that shorten .035", there are times I form cases that shorten .035" when forming before firing. What is a reloader to do? I ask. I look for long cases, my favorite cases are long cases, problem. manufacturers of cases do not sell long cases for reloaders that know what they are doing.

F. Guffey

Last edited:

Case life depends entirely on the load used. And nothing else.

Can you explain this further ? At a glance I disagree completely with that statement .

I had head separation with 308 cases after only 3 loadings

The cases on the left were loaded 3 times , the cases on the right were loaded 8 times . I took pliers to the bad ones on the left but you can see the head separation of one of the cases on the left and the one next to it is about to go . These cases were loaded close to minimum charge do to the fact that was my most accurate load at the time . What is different from the two sets of cases is the cases on the left were sized with excess head clearance of .008+ each time they were FL sized . The cases on the right were FL sized with only .002 head clearance .That was only after I learned that if your die and standard shell holder make hard contact with press cam over . You will likely size the case to short creating excess head clearance when the round is chambered . That excess clearance will cause your case to stretch more then it should each time it is fired , reloaded and fired again . This reduces case life by a whole bunch . After learning how to just bump my shoulders back a few thousandths I have not had another head separate Regardless of the charges . I should add I load for accuracy and rarely have my most accurate load also be a heavy charged load so 95% of my loads are at mid charge or lower .

Last edited:

the only way for that to happen is stretch in that area where the sides of the case meet the head. It also winds up widest in that area, which is called the pressure ring

Unclenick, I am the fan of cutting down on all that case travel. I am also the one that is a fan of understanding design, meaning there are different rules for different designs. Like the firing pin taking/driving the bullet, case and powder to the shoulder of the chamber before busting the primer. I have cases that have shoulder disappear and become part of the case body and the shoulder of the case when fired is new meaning the old shoulder is an artifact.

I want nothing to do with members of this forum requiring therapy because they have no clue what I am talking about. I like things in neat little bundles, I can only guess that drives some to the curb.

F. Guffey

It is possible for a few to determine if the shoulder became an artifact or out ran the firing pin to the front of the chamber.

I dug out the Model 70 I sent back to Winchester. That was the one we had words about, the one with the ugliest chamber, the one that was too large in diameter and too long from the belt to the shoulder of the chamber. They wanted me to shoot it more

Last edited:

Wendyj :

Sorry I can't help with your pics of the 7mm mag cases . I don't have experience with that round so I don't know if they look good or not .I'm sure Unclenick and other can help you with those . My post above was my 308 experience and wanting T.O'heir to clarify what he meant . Was he talking about all cases or just the 7mm mag / belted cases .

Sorry I can't help with your pics of the 7mm mag cases . I don't have experience with that round so I don't know if they look good or not .I'm sure Unclenick and other can help you with those . My post above was my 308 experience and wanting T.O'heir to clarify what he meant . Was he talking about all cases or just the 7mm mag / belted cases .