EastSideRich

New member

I have a S&W 5906.

Shot it outside this weekend (temp was at or just below 0 with a healthy wind-chill).

The gun hasn't ever had a malfunction except one time at the range had 3 failure to eject with Sellier & Bellot over the course of < 50 rounds. I may need a new ejector, but I think this is unrelated.

Anyway, This weekend I had a failure to feed where I believe the top of the casing where the bullet is seated got hung up on the edge of the chamber (shooting WWB). It actually peeled about a 1mm wide strip of the brass back a couple of mm.

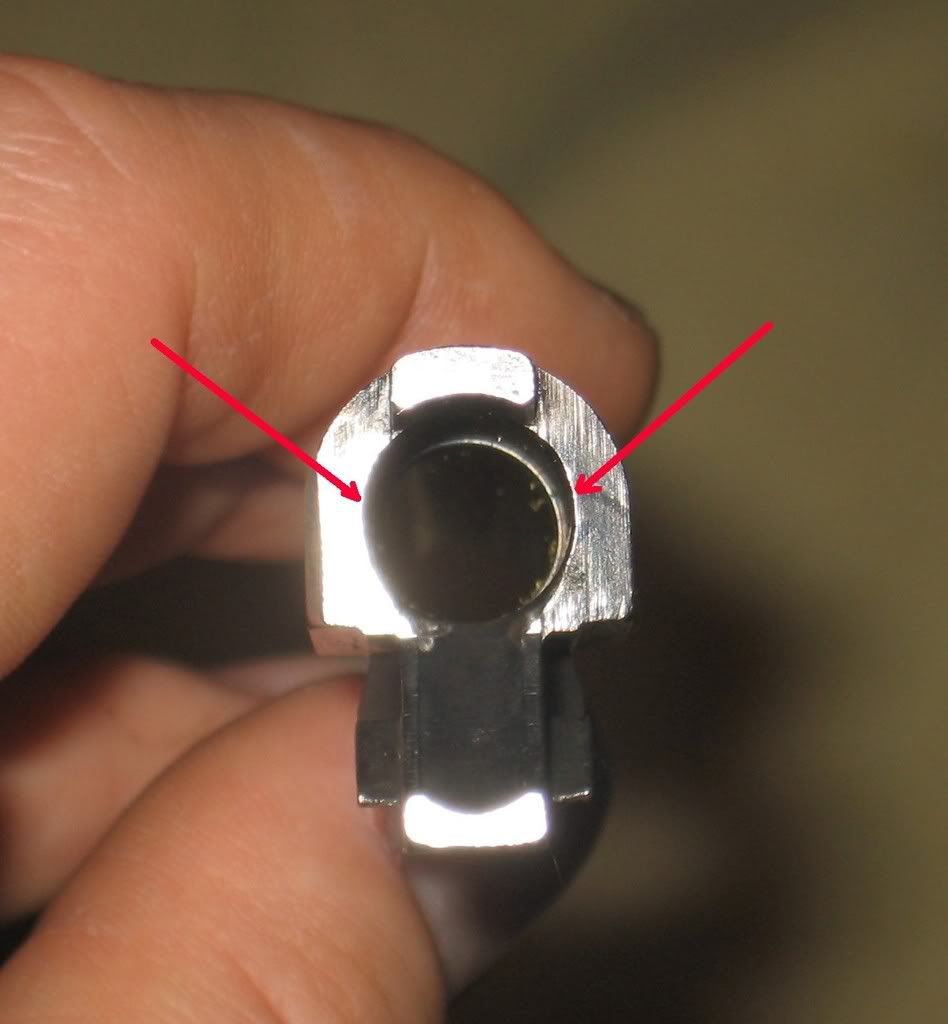

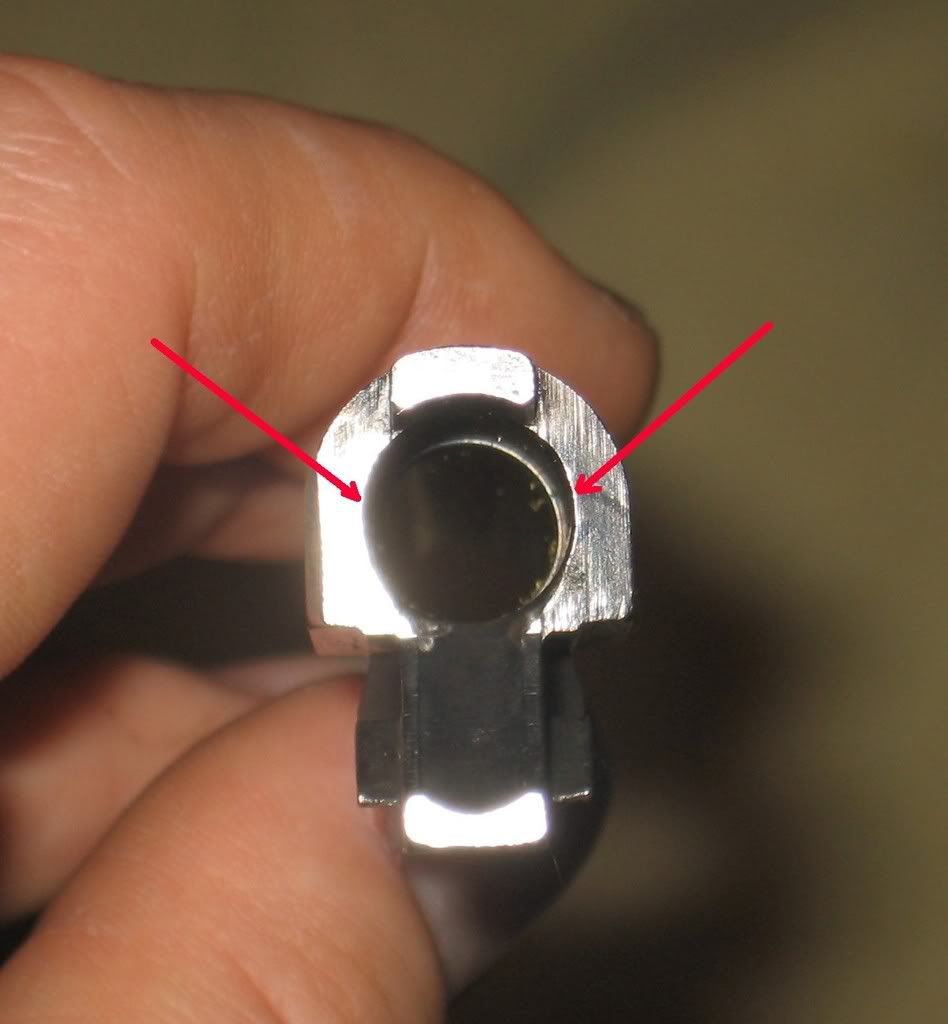

The edges of the chamber end of the barrel are a sharp 90 degrees.

What I was thinking of doing was just kissing these edges (see picture) with a dremel to soften this corner so there is not as sharp of an edge to get hung up on. When a round is seated in the chamber it is not tight, there is about a 1-2 mil gap on between the case and this edge on either side.

Is there any reason I should not do this

Shot it outside this weekend (temp was at or just below 0 with a healthy wind-chill).

The gun hasn't ever had a malfunction except one time at the range had 3 failure to eject with Sellier & Bellot over the course of < 50 rounds. I may need a new ejector, but I think this is unrelated.

Anyway, This weekend I had a failure to feed where I believe the top of the casing where the bullet is seated got hung up on the edge of the chamber (shooting WWB). It actually peeled about a 1mm wide strip of the brass back a couple of mm.

The edges of the chamber end of the barrel are a sharp 90 degrees.

What I was thinking of doing was just kissing these edges (see picture) with a dremel to soften this corner so there is not as sharp of an edge to get hung up on. When a round is seated in the chamber it is not tight, there is about a 1-2 mil gap on between the case and this edge on either side.

Is there any reason I should not do this