Calfpuller,

A die sizes as follows:

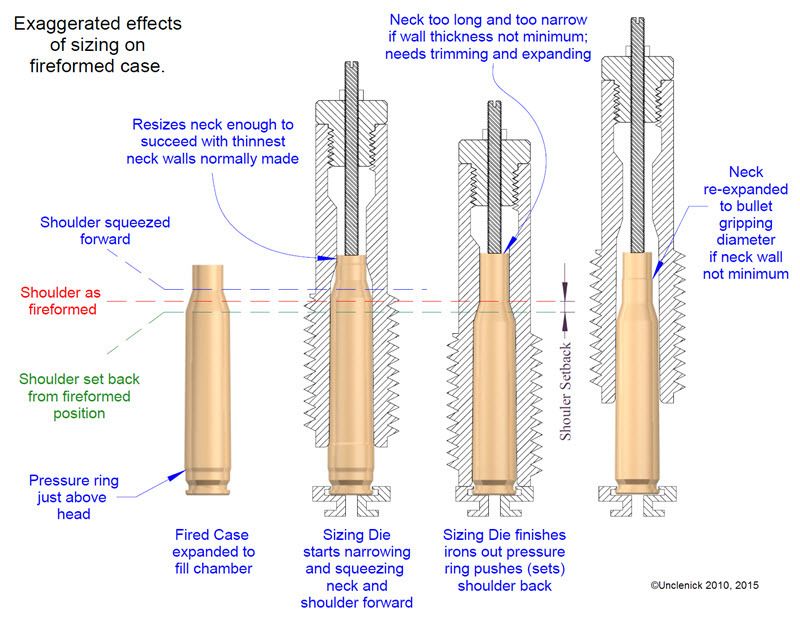

All these images are relative to the shell holder position, so the shell holder stays put and the die comes down so that you can compare the brass lengths. Notice how, in the first sizing drawing, second from left, the brass, which has been fattened by expanding to fill a chamber, first gets squeezed longer because it gets narrowed first by the die, and that squeezed brass has to go somewhere. When you bring the die down far enough (second sizing step, third from left), it is then that the shoulder is pushed back where it is supposed to be, and the excess brass then flows into the neck. It is that last step that causes you to need to trim brass from time to time. People who use neck sizing only almost never need to trim brass.

Also, in general, once-fired brass is military brass that has often been run through the loose chamber of a fully automatic military weapon. This stuff is often fatter than normal and longer than normal, having been stretched by hard extraction. So there are times when even a properly adjusted standard sizing die can't squeeze them back past their spring threshold. On those occasions, you can use a separate small base die which squeezes them down a bit extra, or you can try sizing the two or three times, letting the brass rest up inside the die for five seconds each time, which often gets another couple of thousandths of shoulder setback. Board member F. Guffey has a simple trick, which is he cuts out a piece of shim stock so it slips between the head of the case and the bottom of its slot in the shell holder. You can usually fit 0.005" shim stock in there, and often something even thicker. By raising the head up in the shell holder, you let the sizing die shorten it that much more during resizing.

As to your current predicament, Mehavey's suggestion is right with most dies, because they mostly have a separate expander ball held in place by a decapping pin chuck. Your Lee, however, has them all as one piece. So if you want to use the Lee die, you will want to remove the decapper/expander rod, size the brass again, perhaps using the shim stock, and afterward put the rod back in place and run the brass up onto the die just far enough to expand the mouth of the case, but not far enough to decap the live primer.

It's a good idea, when manipulating brass with a live primer, to be wearing safety glasses and hearing protection. They can be surprisingly loud and throw a shower of sparks.