Ok, please talk me out of this.

I've been working with 45-70 loads for the past two or three years. Right now, it's the only rifle round I'm loading, and I'm only loading it for one gun.

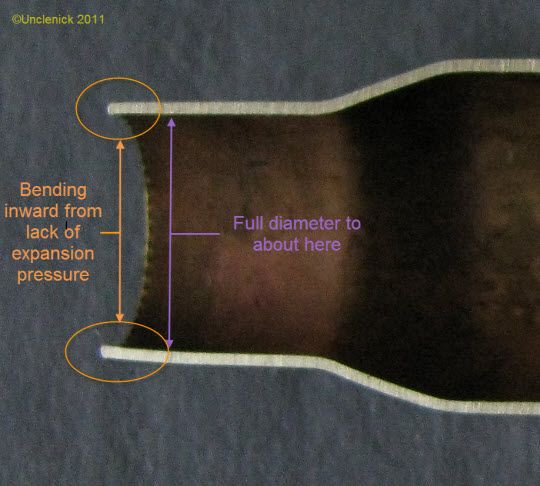

I'm mainly using Star Line brass, which is advertised as tougher/thicker/whatever (they say that the necks often have to be annealed if you want a complete gas seal).

My loads are in the trapdoor level, very low pressure. The cases chamber fine after they've been shot and cleaned. The neck tension seems almost exactly the same as when I do my normal case prep.

So, what is the downside of just skipping the resizing processing??

I've been working with 45-70 loads for the past two or three years. Right now, it's the only rifle round I'm loading, and I'm only loading it for one gun.

I'm mainly using Star Line brass, which is advertised as tougher/thicker/whatever (they say that the necks often have to be annealed if you want a complete gas seal).

My loads are in the trapdoor level, very low pressure. The cases chamber fine after they've been shot and cleaned. The neck tension seems almost exactly the same as when I do my normal case prep.

So, what is the downside of just skipping the resizing processing??