You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

identiying loads

- Thread starter xandi

- Start date

I usually mark the extractor groove of a rifle case with a marker. For low pressure rounds, like 45 ACP, you can mark the heads directly, but the ink does transfer to the breech face. It's common for bull's eye match shooters to mark all their cases so folks on adjacent firing points will return them when the pick them up during policing of brass. Some guys at matches used to use several colors to personalize their marks that covered the whole head. That would transfer enough for the breech face on the slide to become gummy by the end of a match and be in need of some acetone to clean it off. I've also tried putting ink down in extractor grooves to mitigate the transfer, but other people don't look there and it's not convenient for me to look at, either.

My dad got tired of the ink marking routine and used a hacksaw to put grooves across the heads of his 45 ACP cases. He bisected the head with them going straight across the primer pockets to about the depth of their mouth radius. With the target loads we were using in bull's eye matches then (about 4 grains of Bullseye under 200 grain cast bullets) the primer showed no tendency to flow into the grooves at all.

Another method I've used with 308 cases in the past is to hit the head with an automatic centerpunch with its spring unscrewed to a minimum marking force. I used that to keep track of the number of reloads my M1A cases had for awhile. The problem with it is the punch raises the surface slightly around the dimple it makes in the brass. That flattens back out on the next firing, but for high precision it's a potential source of an additional recoil moment, so I wouldn't count on drilling bugholes with cases marked by such a tool until after the first flattening out had been completed. I saw no effect for service rifle accuracy purposes, but YMMV. Test it in your gun.

You can also use a small triangle file to notch a rim. For self-loaders, that could make a weak spot for tearing, but for a bolt rifle not firing loads so hot you have sticky extraction, it's fine.

My dad got tired of the ink marking routine and used a hacksaw to put grooves across the heads of his 45 ACP cases. He bisected the head with them going straight across the primer pockets to about the depth of their mouth radius. With the target loads we were using in bull's eye matches then (about 4 grains of Bullseye under 200 grain cast bullets) the primer showed no tendency to flow into the grooves at all.

Another method I've used with 308 cases in the past is to hit the head with an automatic centerpunch with its spring unscrewed to a minimum marking force. I used that to keep track of the number of reloads my M1A cases had for awhile. The problem with it is the punch raises the surface slightly around the dimple it makes in the brass. That flattens back out on the next firing, but for high precision it's a potential source of an additional recoil moment, so I wouldn't count on drilling bugholes with cases marked by such a tool until after the first flattening out had been completed. I saw no effect for service rifle accuracy purposes, but YMMV. Test it in your gun.

You can also use a small triangle file to notch a rim. For self-loaders, that could make a weak spot for tearing, but for a bolt rifle not firing loads so hot you have sticky extraction, it's fine.

g.willikers

New member

Write the necessary info on the bullets?

Sorry, couldn't help myself.

Sorry, couldn't help myself.

Write the necessary info on the bullets?

I used to do that, but then found I still couldn't find my brass back..........

Chainsaw:

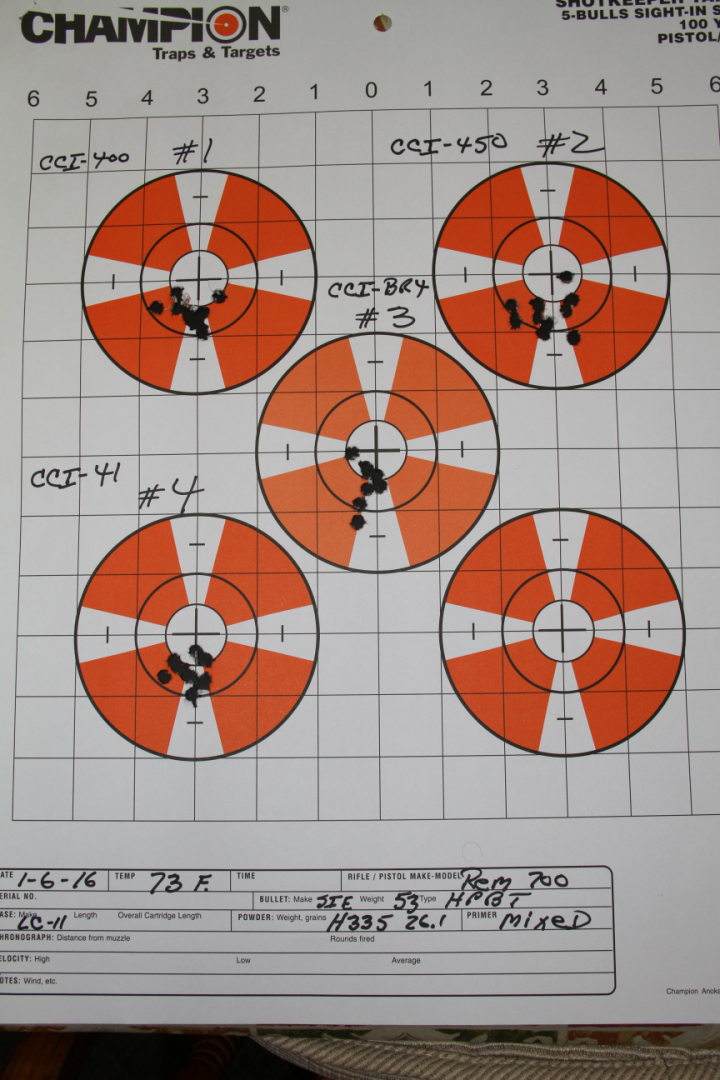

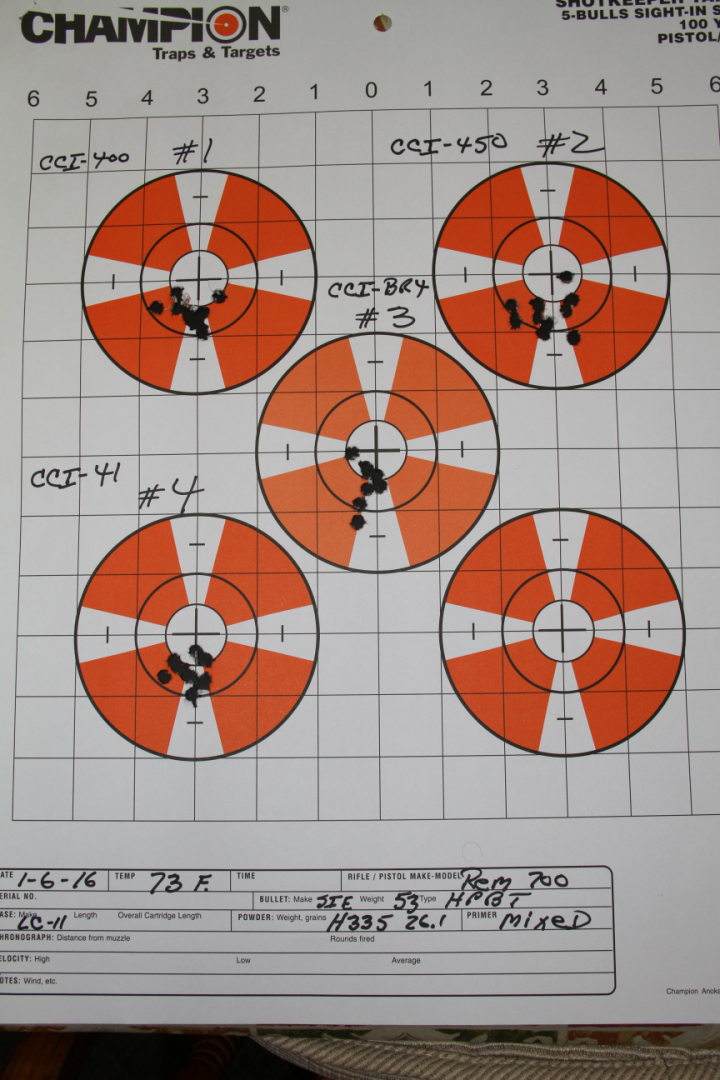

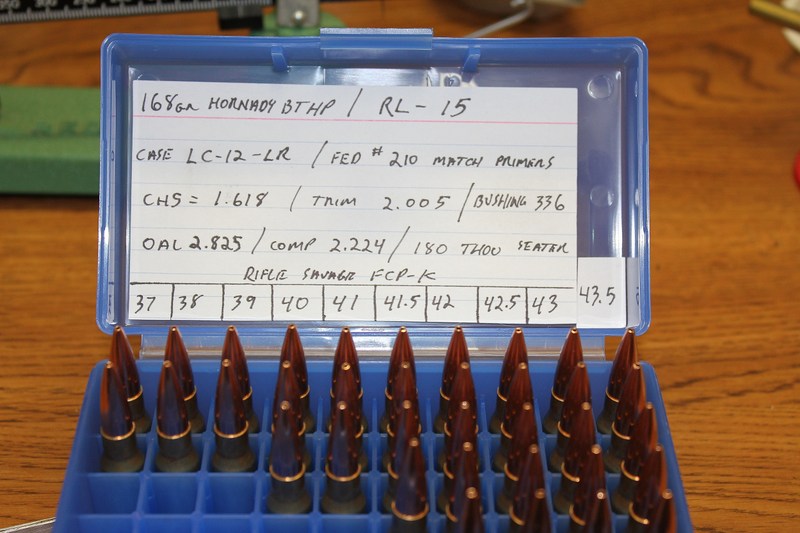

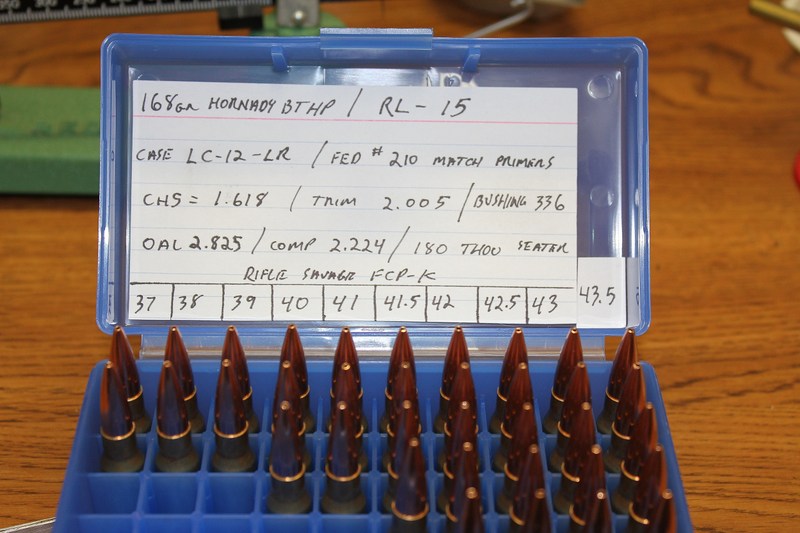

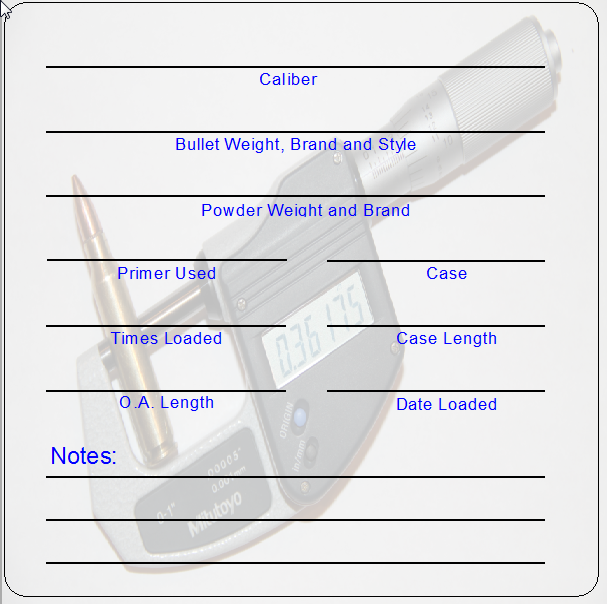

When I have large numbers of cases that is what I do. I cut down 3x5 index cards to fit the cases and each case has a label on the top with the complete load data. Here is an example, all cases have identical loads with only the primers changing. Originally for a velocity test so the chronograph print outs are included in each case. I then mark the target(s) for the loads.

For small lots of 5 or so cases I just use a magic marker and place dots on the cases and index the dots.

Ron

Permanent marker on the case. Or put them in those little plastic case boxs with a peice of paper behind them identifying the load.

When I have large numbers of cases that is what I do. I cut down 3x5 index cards to fit the cases and each case has a label on the top with the complete load data. Here is an example, all cases have identical loads with only the primers changing. Originally for a velocity test so the chronograph print outs are included in each case. I then mark the target(s) for the loads.

For small lots of 5 or so cases I just use a magic marker and place dots on the cases and index the dots.

Ron

OP,

Can you be more specific as how you mark your brass and how that marking identifies something and how you know what it identifies ?

I generally understand what your asking but don't see how marking the case identifies anything but that it's your case .

The more info the better for me . At times I will not get to shoot what I loaded for a long time . In the past I thought I labeled things well only to realize I forgot what I meant .

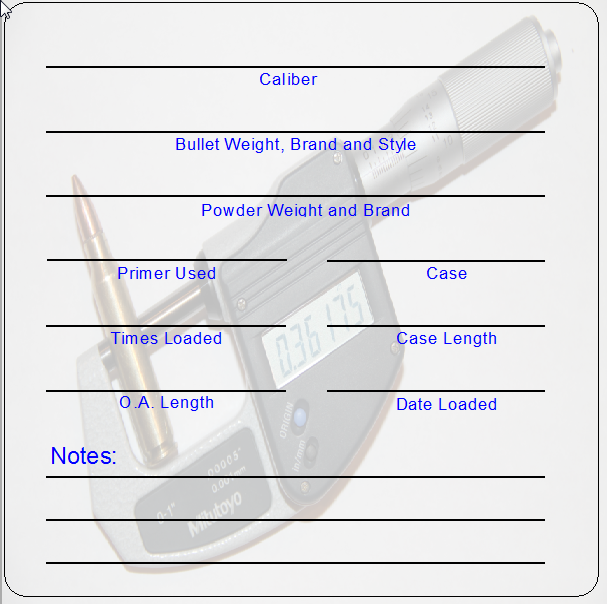

Here's what mine look like now with clearly defined charges and components as well as high lighted over max charges .

If I have different components in the same box . Those differences are written out and the rounds identified by lines and or arrows or something . I do my best to capture all cases as they're ejected during load development and returned to there original place in the box for future reference .

If there was an issue when fired . That case or set of cases are returned to the box up side down to remind me there was an issue and to look at my corresponding notes later as to what that was .

Can you be more specific as how you mark your brass and how that marking identifies something and how you know what it identifies ?

I generally understand what your asking but don't see how marking the case identifies anything but that it's your case .

The more info the better for me . At times I will not get to shoot what I loaded for a long time . In the past I thought I labeled things well only to realize I forgot what I meant .

Here's what mine look like now with clearly defined charges and components as well as high lighted over max charges .

If I have different components in the same box . Those differences are written out and the rounds identified by lines and or arrows or something . I do my best to capture all cases as they're ejected during load development and returned to there original place in the box for future reference .

If there was an issue when fired . That case or set of cases are returned to the box up side down to remind me there was an issue and to look at my corresponding notes later as to what that was .

Last edited:

Hmmm. I guess my methods are different(?). I will make up a few rounds of a new load and put them in slide lock bags. I use data labels I print on Avery labels and stick those on the bags. I keep the loads separate, and don't mix a string so there is no trouble identifying any ammo. I only shoot one load per target so that's easy to keep separate too (I number the targets and use the same number on the data label. Normally use a marking pen at the range). When I get home I write the info on the target (if it's a good, keeper load) and put the target in a binder. Works for me, and no mixed up loads/data...

mikld:

Makes for a very good point. Avery Label Software is a free download from Avery Label and the labels in all sorts of sizes can be had from any office supply store.

Easy to roll your own labels for plastic ammo storage boxes customezed how you want them:

Ron

Hmmm. I guess my methods are different(?). I will make up a few rounds of a new load and put them in slide lock bags. I use data labels I print on Avery labels and stick those on the bags.

Makes for a very good point. Avery Label Software is a free download from Avery Label and the labels in all sorts of sizes can be had from any office supply store.

Easy to roll your own labels for plastic ammo storage boxes customezed how you want them:

Ron

Assuming you're working up 5 rounds of each load a stripper clip works well. Most typical deer hunting cartridges will fit a 7.62NATO stripper clip with no fuss. They're not horribly expensive either and a post-it note or plain old masking tape will stick. Or put the clip into an M1 Rifle ammo belt. Holds 80 rounds with 2 clips per pouch.

Or you can just load 4 of each and put 'em in a marked factory box.

Oh and a Sharpie is your friend. Simple numbering the load and putting that on the case works too.

"...info on the bullets..." Um, no. That's where the "This one's for you, Wiley!" goes on my .243 90 grain FMJ's. snicker.

Or you can just load 4 of each and put 'em in a marked factory box.

Oh and a Sharpie is your friend. Simple numbering the load and putting that on the case works too.

"...info on the bullets..." Um, no. That's where the "This one's for you, Wiley!" goes on my .243 90 grain FMJ's. snicker.

Jim Watson

New member

I color code the primer or/and bullet. Then put a card with the code in the box or bag. That way there is nothing on the case to confuse the next test programme.

I had one box without color code listed row by row. But I spilled the box.

I had one box without color code listed row by row. But I spilled the box.