bushmaster65

New member

Went to the range today with my 2nd Gen Dragoon. She was binding up awfull bad from fouling. Think I'm putting too much Ballistall on her and the residue is just turning to mud when the oil soaks it up.

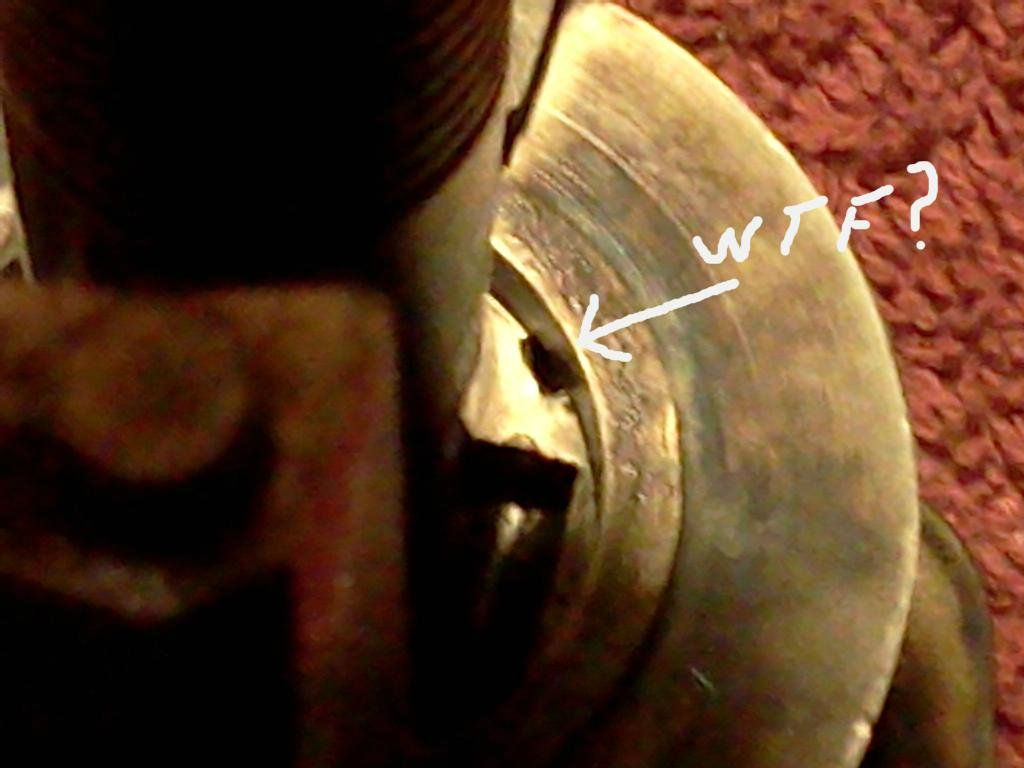

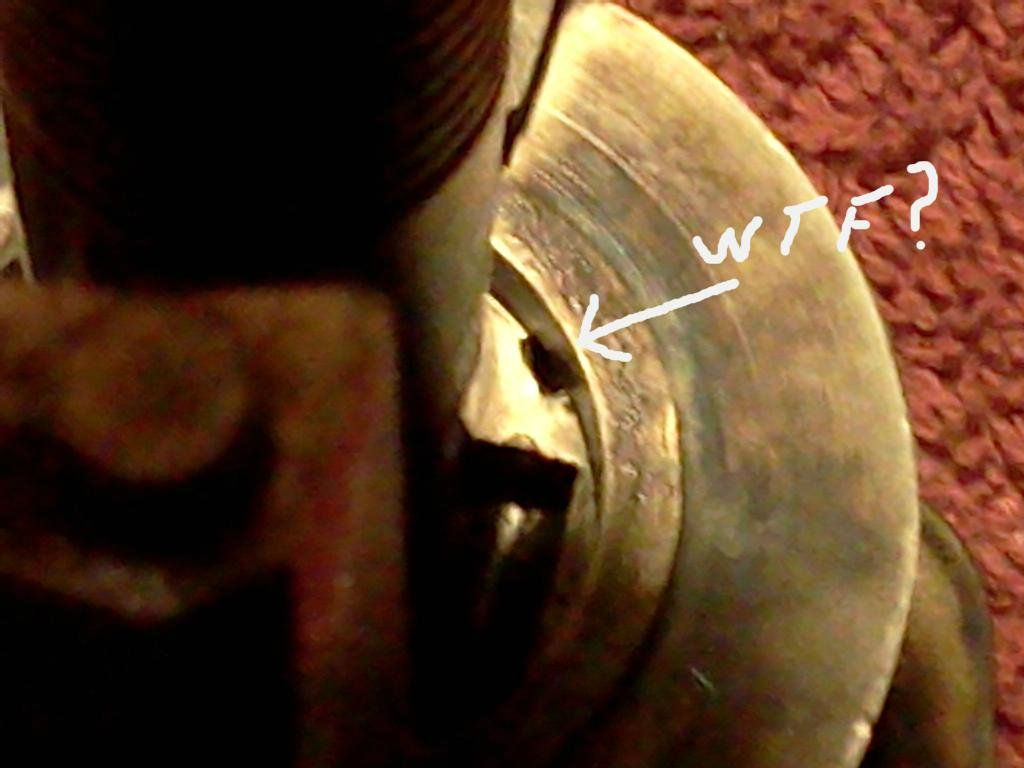

But whilst cleaning her tonight, I found a hole just above the cutout for the hand assembly. I know damn well it wasn;t there the last time I shot it. I'm assuming when they reamed the hole for the hand assembly they cut to close to the face of the recoil shield and made it paper thin.

Has anybody else had this problem???

But whilst cleaning her tonight, I found a hole just above the cutout for the hand assembly. I know damn well it wasn;t there the last time I shot it. I'm assuming when they reamed the hole for the hand assembly they cut to close to the face of the recoil shield and made it paper thin.

Has anybody else had this problem???

Last edited: