Howdy

One of my favorite subjects.

First of all, you have to define 'back in the day' which is, with all due respect, a meaningless term.

Secondly, you are mistaken when you say 'they didn’t have all the fancy tools and machines that we have today'. The machine tools in use at the time may not have looked much like the machine tools available today, but they did exist, and were designed to reproduce many, many parts to close tolerances.

The Industrial Revolution took place from about 1760 to about 1840 or so. This is when manufacturing techniques moved from parts being made one at a time, to mass production. Certainly within the time period of the Pepperbox. Also within the time period when all the major arms manufacturers began moving from making one gun at a time to making large quantities of interchangeable parts that could be assembled into more complex assembles without a whole lot of individual fitting.

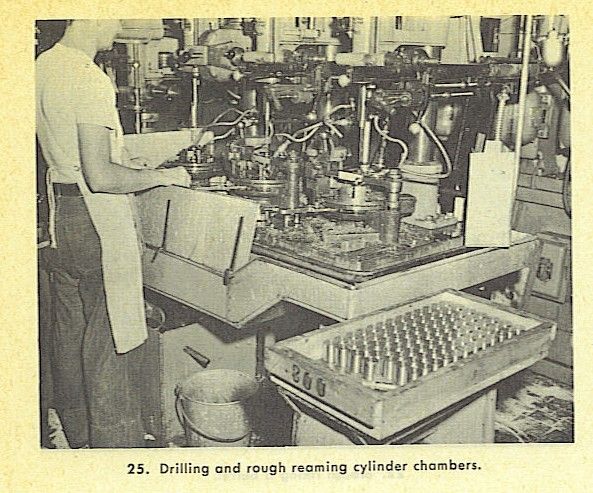

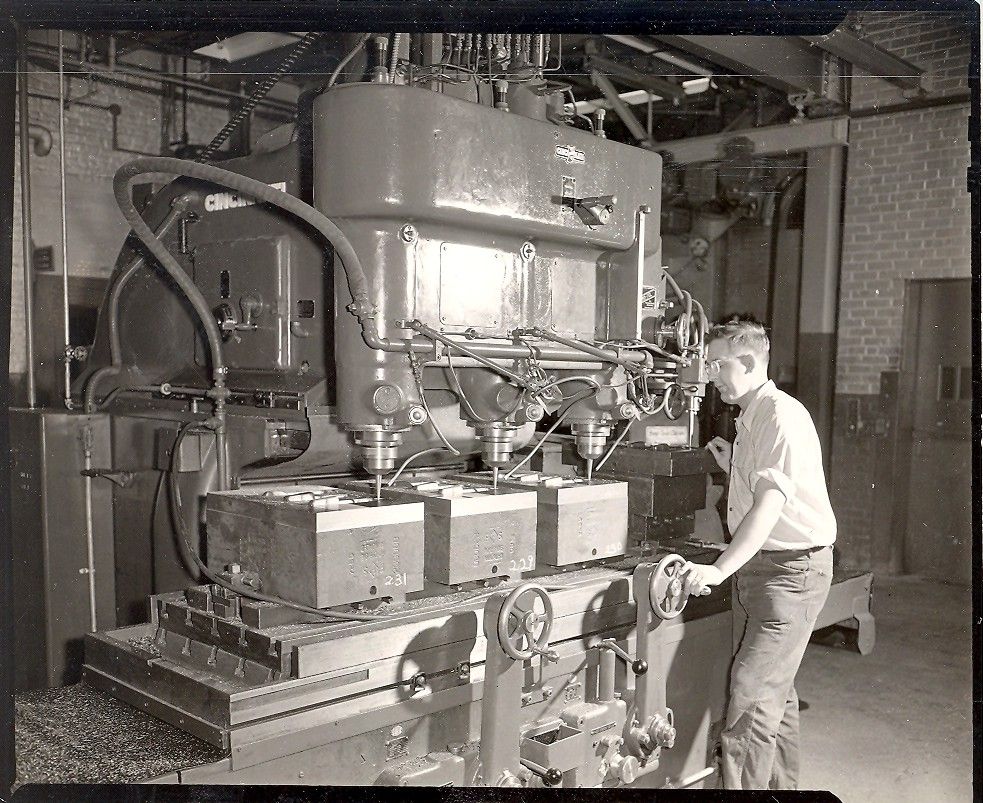

Here is a photo from a photo essay that Smith and Wesson put out about 1950 when they built their 'new' factory. Which is still in use today. The equipment inside has changed over a lot, but the building is still in use.

S&W, as well as all the major gun manufacturers, used work stations that were dedicated to one specific operation. Parts would move from one work station to another as they progressed from raw steel to finished parts.

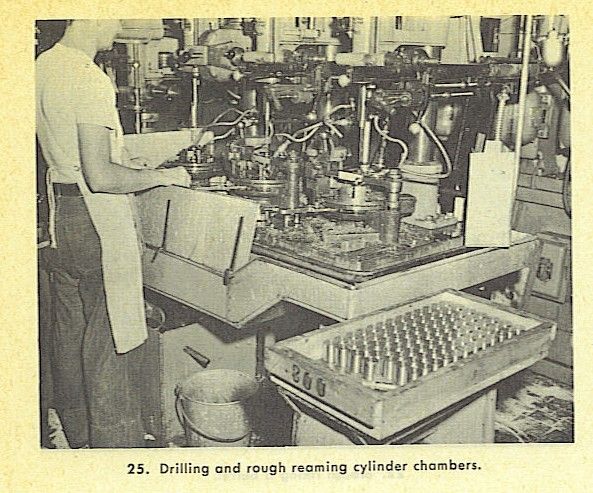

Here we see the work station for rough drilling the chambers in revolver cylinders. The round blanks, which had been previously turned on a lathe, were brought to this work station. Notice there are several drill press heads mounted on the work station. Underneath each drill press is a rotary table. Each rotary table would already have been set to drill six holes by turning the table 60 degrees for each hole. Most likely the cylinders progressed from one drill head to the next for different drills. Maybe a centering drill to begin with, then a larger drill and so on until the final dimension was achieved. Notice the large tray of cylinders that have had their holes drilled.

This was just one step in making cylinders in 1950. There were several more work stations the cylinders had to go through before they were finished. Interestingly enough, at the beginnig of this photo essay it says there were over 2000 separate operations to go through in making a revolver, and more than 500 inspections.

Here is a really good video showing the basics of using a rotary table to drill multiple holes evenly spaced around a circle, much like you would find in a revolver cylinder. Forget the fact that he is using a modern miller with a digital readout, the method of using a rotary table is not any different than it was back in 1950. Or earlier. Note that in a production setting such as the work station at S&W, all the tedious set up time would already have been done. The rotary table would already be all set up, so all six holes could be drilled quickly and efficiently.

https://www.youtube.com/watch?v=CxFHU7NxRWE

Today of course, I suspect cylinders can be turned and drilled on multiple head machining centers without removing them from the machine, but that is how it used to be done.

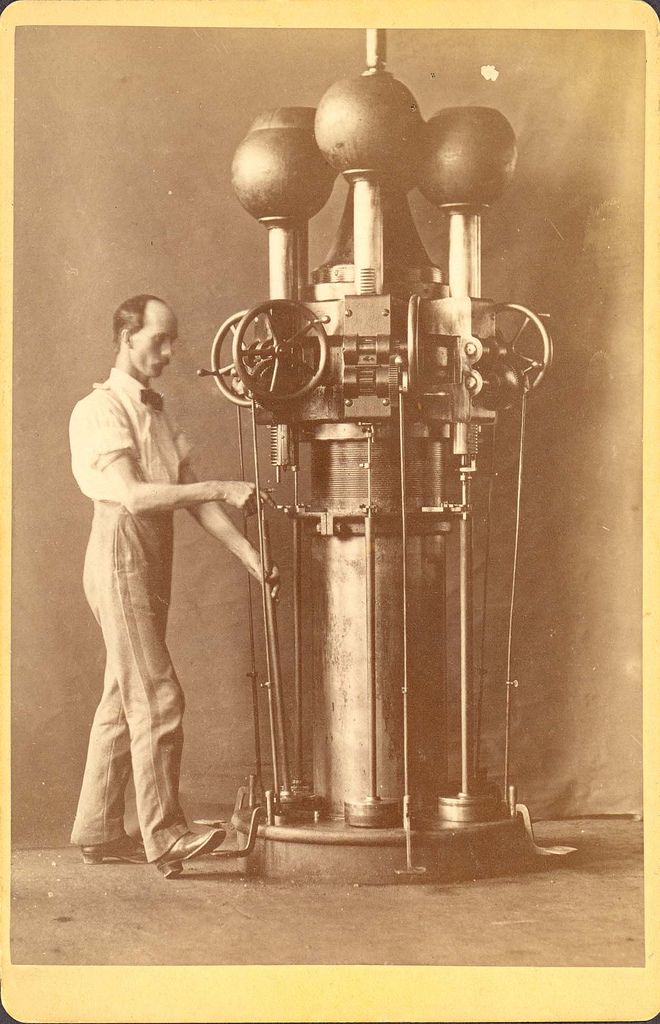

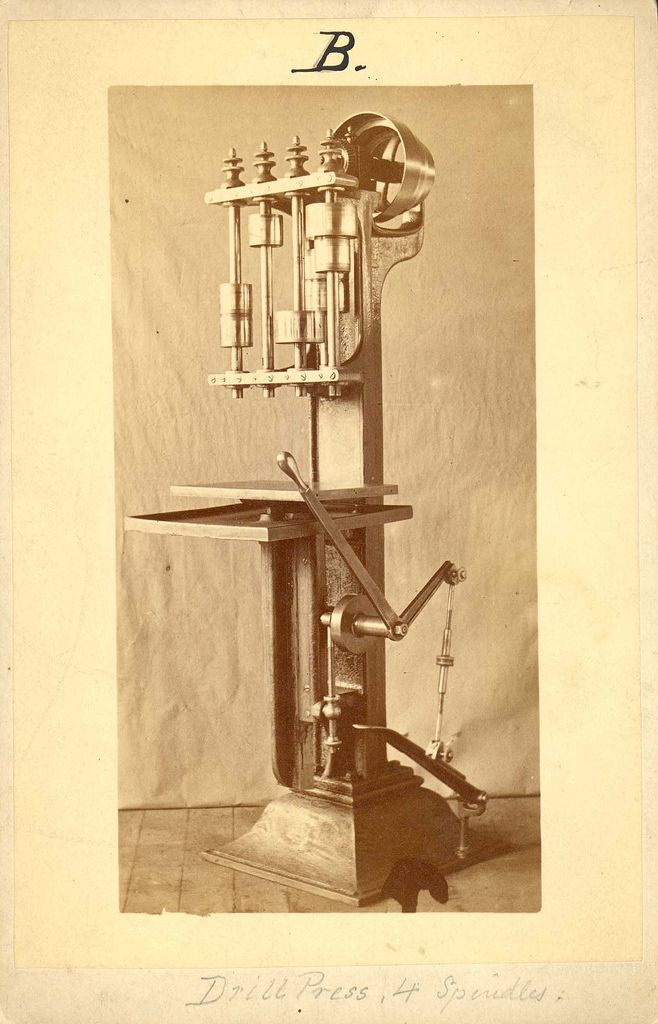

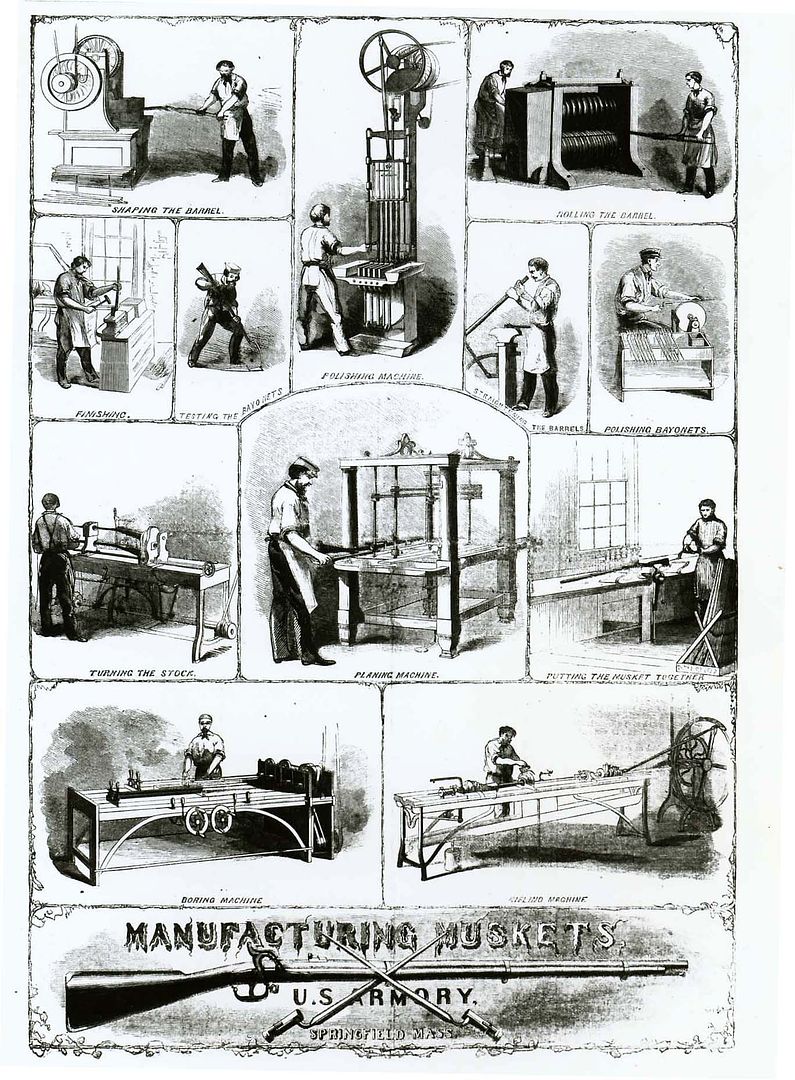

Just for the fun or it, here are some photos of old equipment that was used manufacturing firearms many years ago.

This is a barrel drilling machine from the 1800s used at Colt.

A four spindle drill press.

This illustration shows equipment used to manufacture muskets at the Springfield Armory during the Civil War.

Row upon row of machines at the Springfield Armory, each one set up to do a specific operation. Notice all the machines are driven by belts that reach up to line shafts near the ceiling. The Springfield Armory was originally built during George Washington's presidency on the present site because abundant water power was available form the Connecticut River. But by the time this photo was taken stationary steam engines were providing the power.

Here is something you don't see every day. This is how multiple parts with complex geometry were produced long before Computer Numerical Control (CNC) existed. This is a pattern following miller. There are three heads that are working on three work pieces at once. The operator's right hand is resting where a pattern was secured. The thin vertical piece is a stylus. The operator operated the hand wheels to keep the stylus pressed against the pattern, and the machine followed the pattern through a mechanical linkage to cut the pattern in metal. Judging from his clothes this photo was probably taken around 1940 or 1950.

Pattern following equipment goes back much further than that. If you are ever in Vermont, stop in at the American Precision Museum to see how modern manufacturing methods for mass producing parts evolved in the 1840s.

https://www.americanprecision.org/