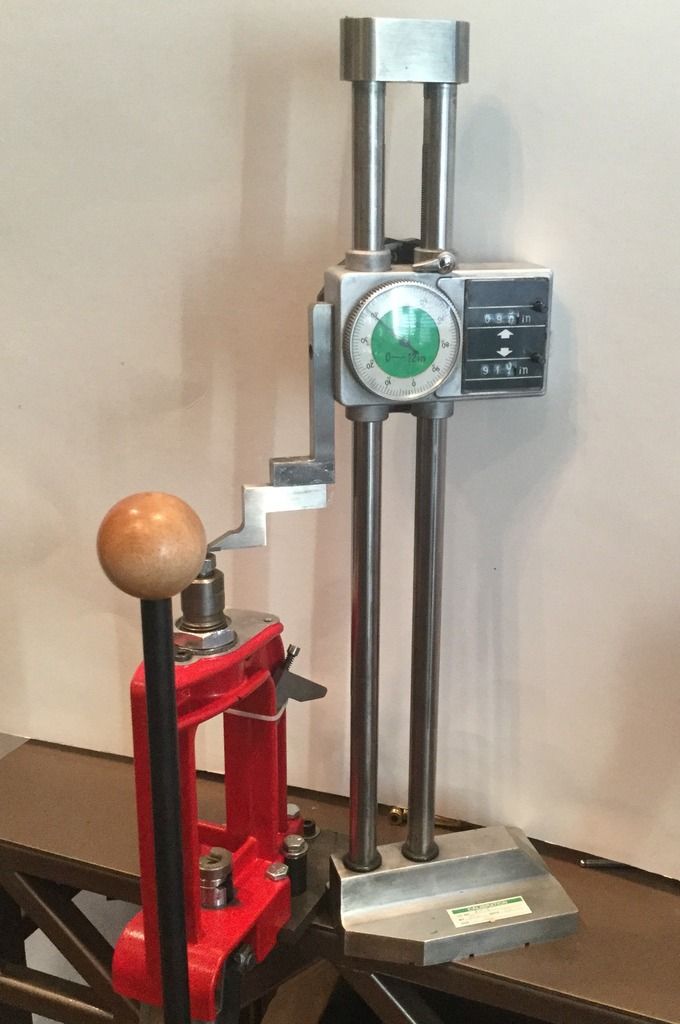

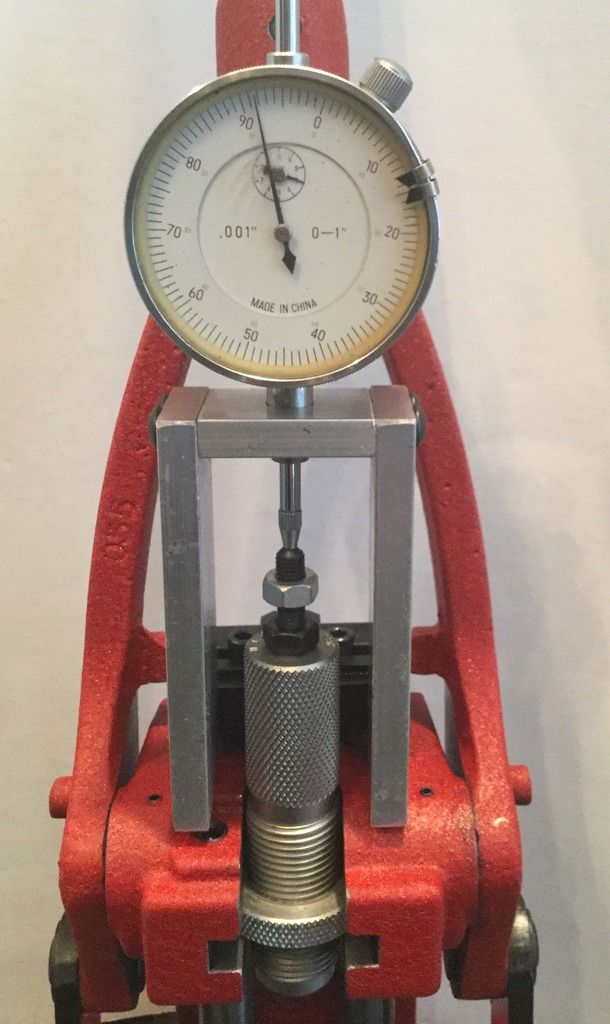

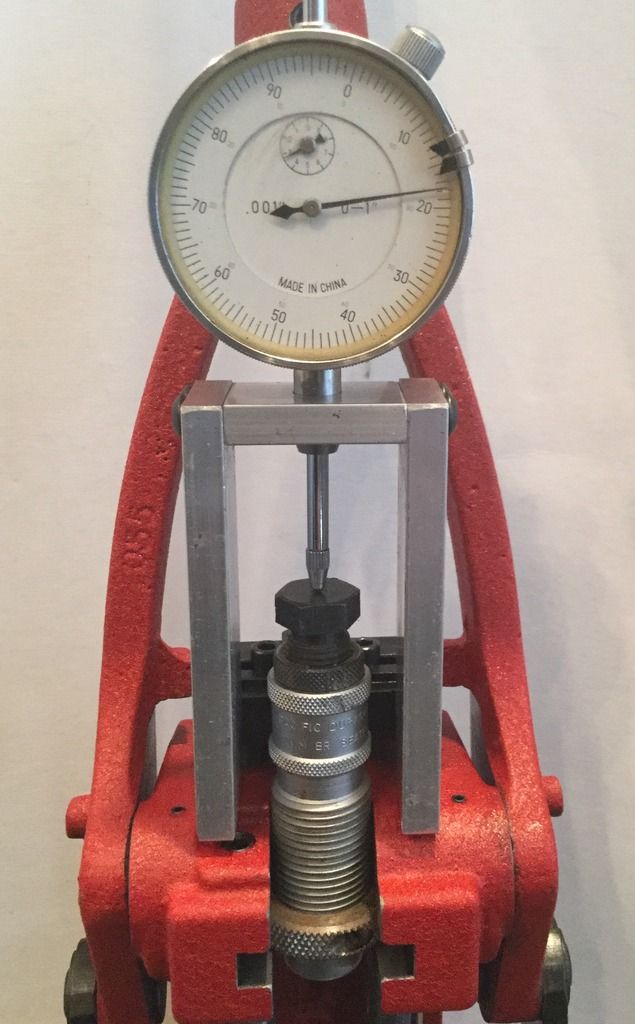

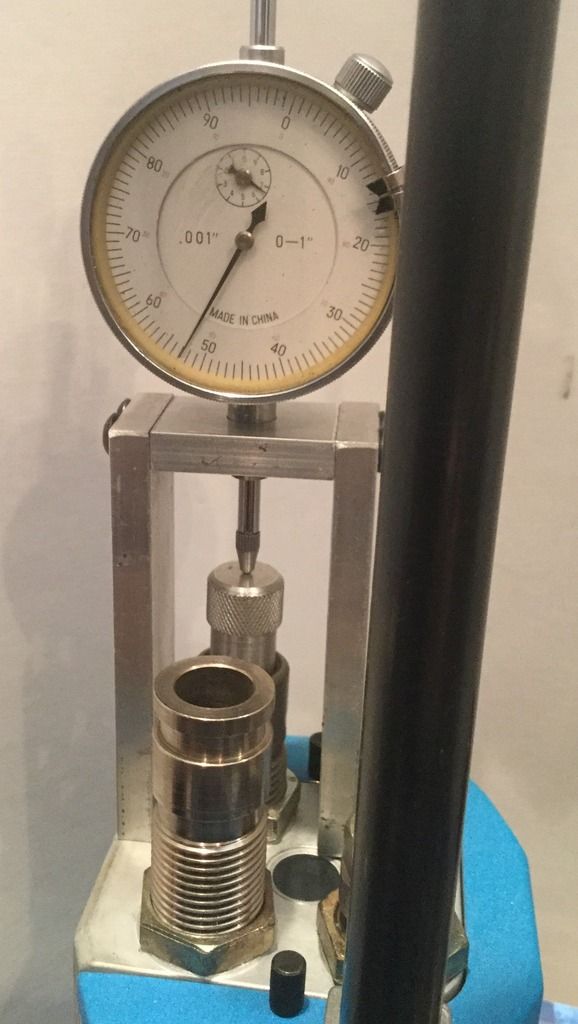

There are reasons to own various dies but if being able to simply accurately set and adjust depth from one position to another you can save a lot of money making a "beginners level" tool vs buying a special die.

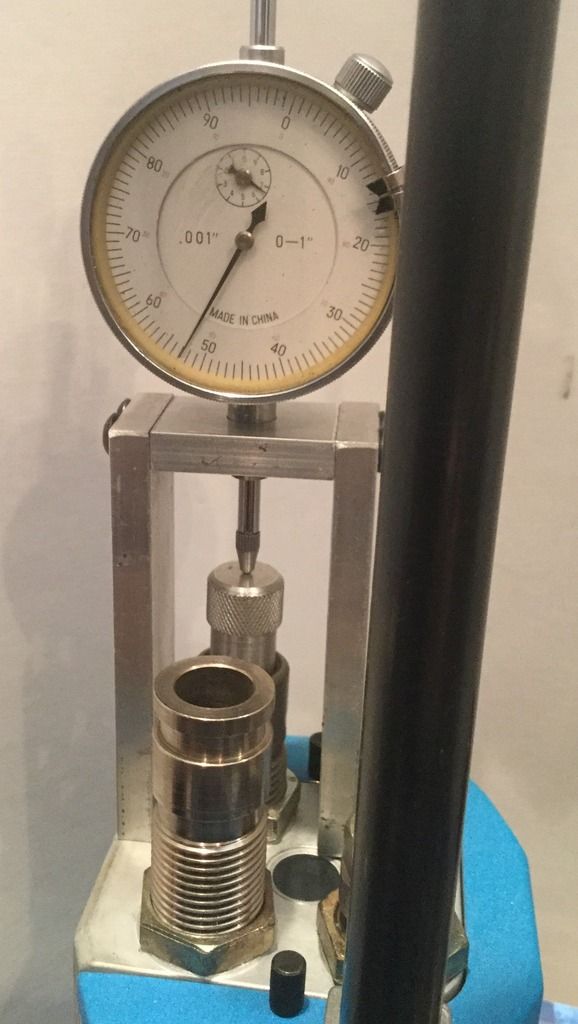

All it does is hold an indicator off a surface, as long as you don't move it it will measure any change in height as you adjust the die.

The surface really doesn't even need to be flat, as long as it is stable and doesn't move while you are adjusting.

Some dies like Lee for example have a convex shape to the top, it is best to face them off flat or hit the center with a center drill.

At that point is really doesn't matter if the surface it rests on is perfectly level, it still works fine.

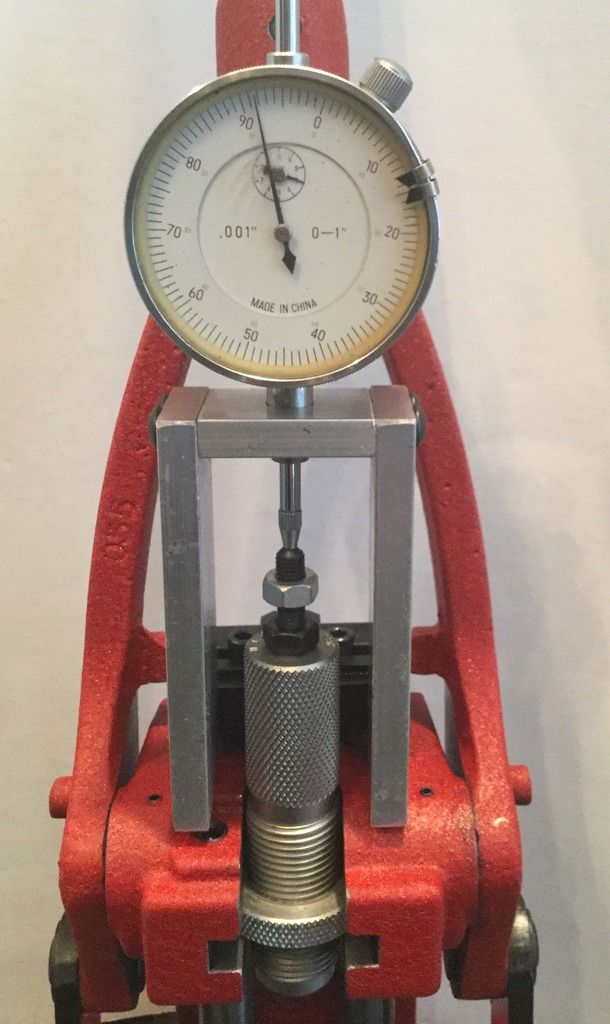

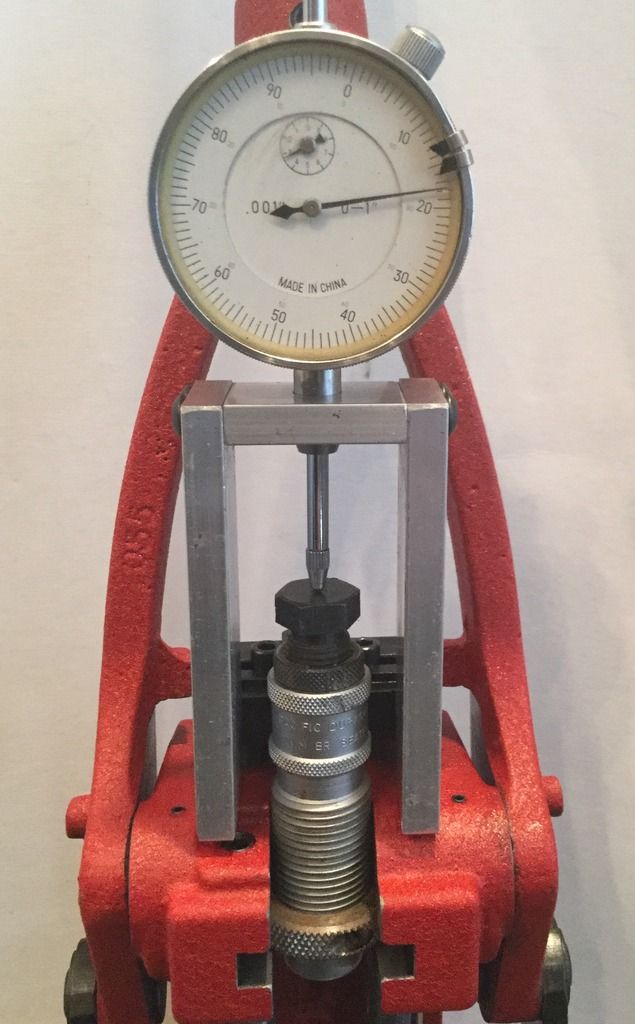

Some dies like RCBS have a slot for a flat blade in the seating stem. If you take a 1/4-28 nut and thread half the depth onto the stem then thread a 1/4-28 set screw, hex side down, until it bottoms on the stem, you now have a centered surface to indicate from and a "knob" to turn for adjustment.

All it does is hold an indicator off a surface, as long as you don't move it it will measure any change in height as you adjust the die.

The surface really doesn't even need to be flat, as long as it is stable and doesn't move while you are adjusting.

Some dies like Lee for example have a convex shape to the top, it is best to face them off flat or hit the center with a center drill.

At that point is really doesn't matter if the surface it rests on is perfectly level, it still works fine.

Some dies like RCBS have a slot for a flat blade in the seating stem. If you take a 1/4-28 nut and thread half the depth onto the stem then thread a 1/4-28 set screw, hex side down, until it bottoms on the stem, you now have a centered surface to indicate from and a "knob" to turn for adjustment.