PolarFBear

New member

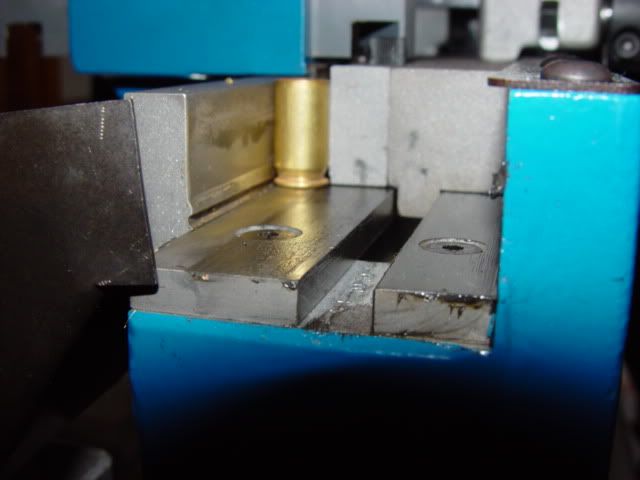

Have loaded several thousand .45 ac rounds on Lee and Dillon equipment. Always separate my cases by headstamp. Never had "brass" issues with anything except AMERC (never ever reload AMERC brass!). BUT: I bought a Dillon case gage chamber checker, just to make sure my rounds were A-OK. I am working through a batch of Speer Lawman. About 25% of the completed rounds will not fully drop into the chamber checker. The cases have little extractor nicks on the case rims. These nicks add just enough interference to jam the round. I tried a file and a utility knife. They work but make the process very slow. As an alternative I now trial fit the rim into the case gage: if it fits OK; if not I cull the brass. My cull pile is growing. Is there a CHAMFER device, like Lee makes for case mouths, that will trim the nicked edges off my rims? Or, am I being to picky and just load as I have been doing for the past 15 years. Oh, it looked SO inviting to just give those little babies a whack with a hammer to seat that round the last .0005 inch, but thought better of whacking the primer (chuckles).