ExPatYankee

Inactive

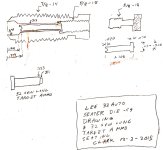

I have a set of Lee reloading dies (3) for S&W long. I reload .32 wadcutter for competition training. For the record it is a Lee-32AUTO-C5 and I reload with a single stage Challenger Kit.

I began by adjusting the die with the aim to seat and crimp simultaneously. The seating element bottomed out so I began dropping the crimp element. Fast forward, I ended up with a nicely crimped set of rounds, but the seating element is, as mentioned, bottomed out. The bullet sticks out of the shell 2-3 millimeters and the round does not feed into the magazine well; strangely enough they feed into the chamber nicely. If I lower the crimp element the bullet seats nicely but the crimp crushes the mouth of the shell. I have heard the phrase "crush crimp" which always seems to be used in the worst way.

I have temporarily solved the problem by seating the bullet with a .38 seating/crimping die in which case I raised the crimp element (may not be necessary due to the size of the shell) and simply seat the bullet. I then have to remove the seating plug on the .32 die and use the crimping element only. Yes, a lot more trouble, but that is all I have to work with at the moment.

My questions for the wizards among you is, how can I fix the problem with the .32 C5 die so that it drops the bullet a little deeper, a mere 3 mm at most, and then get a nice roll crimp? I thought of fixing up a "shim" or a "plug extension" to fill the inner space on the die but that might take longer to create than the method I ended up using above.

Many thanks in advance for any advice.

I began by adjusting the die with the aim to seat and crimp simultaneously. The seating element bottomed out so I began dropping the crimp element. Fast forward, I ended up with a nicely crimped set of rounds, but the seating element is, as mentioned, bottomed out. The bullet sticks out of the shell 2-3 millimeters and the round does not feed into the magazine well; strangely enough they feed into the chamber nicely. If I lower the crimp element the bullet seats nicely but the crimp crushes the mouth of the shell. I have heard the phrase "crush crimp" which always seems to be used in the worst way.

I have temporarily solved the problem by seating the bullet with a .38 seating/crimping die in which case I raised the crimp element (may not be necessary due to the size of the shell) and simply seat the bullet. I then have to remove the seating plug on the .32 die and use the crimping element only. Yes, a lot more trouble, but that is all I have to work with at the moment.

My questions for the wizards among you is, how can I fix the problem with the .32 C5 die so that it drops the bullet a little deeper, a mere 3 mm at most, and then get a nice roll crimp? I thought of fixing up a "shim" or a "plug extension" to fill the inner space on the die but that might take longer to create than the method I ended up using above.

Many thanks in advance for any advice.