My cyq code (Spreewerk, made in Czechoslovakia in 1944, all numbers matching) P.38 has a jam, maybe 50% of the time, when feeding a new round. A slight rearward tug on the slide clears it every time

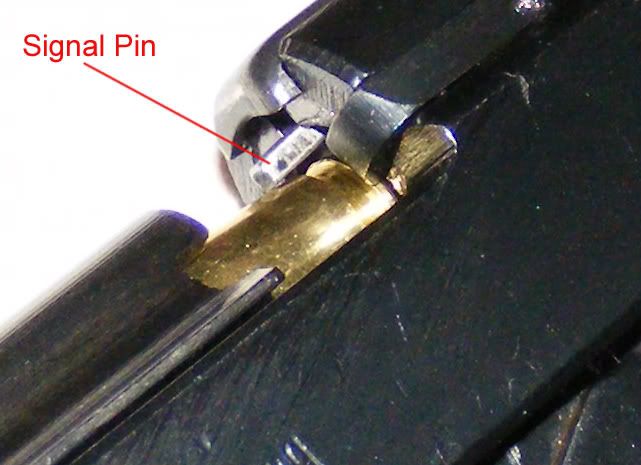

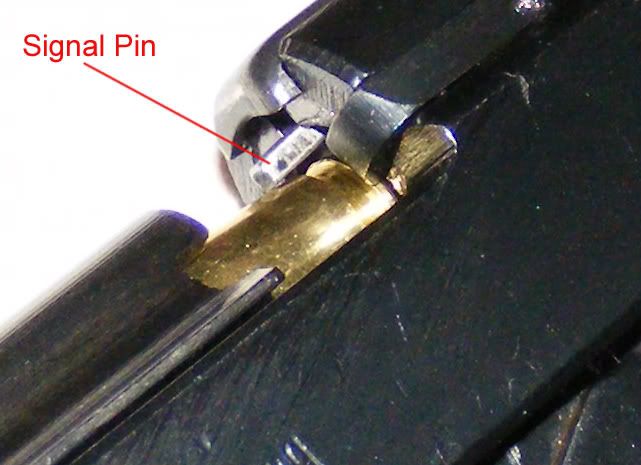

I have replaced the recoil springs. I have hand polished the feedramp (with scotchbrite and finger pressure only). I have removed, inspected, cleaned, de-burred, hand-polished (scotchbrite, finger pressure) and reinstalled the signal pin. I have checked the springs in my mags, they seem fine. Mags are clean

And none of this has made a difference. I have tried three mags, including the correct date-code original P.38 mag, and two modern P1 mags. Identical failures to feed.

Its almost as if something is out of 'time'. As you can see, the round is getting trapped under the signal pin. Somehow, the pin is just not traveling up as it should. I have no manner of doubt that without the signal pin, it would work flawlessly. However, that makes it illegal in my location

A P1 as a shooter is also not possible, as that pistol is also illegal in my location. Yes I know it's 99.99% the same pistol. Tell that to Deval Patrick, not me

Any suggestions? I have learned one thing today though- putting the slide cover back on is a sumbitch!

I have replaced the recoil springs. I have hand polished the feedramp (with scotchbrite and finger pressure only). I have removed, inspected, cleaned, de-burred, hand-polished (scotchbrite, finger pressure) and reinstalled the signal pin. I have checked the springs in my mags, they seem fine. Mags are clean

And none of this has made a difference. I have tried three mags, including the correct date-code original P.38 mag, and two modern P1 mags. Identical failures to feed.

Its almost as if something is out of 'time'. As you can see, the round is getting trapped under the signal pin. Somehow, the pin is just not traveling up as it should. I have no manner of doubt that without the signal pin, it would work flawlessly. However, that makes it illegal in my location

A P1 as a shooter is also not possible, as that pistol is also illegal in my location. Yes I know it's 99.99% the same pistol. Tell that to Deval Patrick, not me

Any suggestions? I have learned one thing today though- putting the slide cover back on is a sumbitch!

Last edited: