This review will cover the Harrison Extreme Service rear sight and the UNI-2ooL Universal Sight Mover I used to install it on my Springfield 1911. But first, a little background on why I changed the sight in the first place.

I bought one of the new Springfield Armory Range Officer 1911-A1 pistols in February 2011. According to Springfield, the Range Officer was created with the idea of offering an affordable, factory production 1911 that was still capable of winning shooting competitions. The idea was to get a pistol in the hands of those wanting to try competition shooting, with enough features to help them win and a solid enough base that they could further customize it if they so desired.

The Range Officer accomplishes that goal. It comes with low profile, fully adjustable target sights. That's good for a competitor because it is easy to finely tune it to sync up with a particular load the shooter favors. However, what's good for target shooting may not be so good for concealed carry or other uses.

The problem is the rear target sight. A target sight is typically made up of angular pieces, which can more easily snag on clothing or other objects. The adjustments are set and kept using screws. In a pistol carried daily, it is more likely that these screws could loosen over time, which could throw your sights off. Finally, target sights are a little more prone to breakage because they are made up of multiple pieces.

Since I am not going to compete or limit myself to target shooting with my Range Officer, I needed to solve those problems while keeping the other great features of the pistol intact. I looked into various sights that would fit the LPA cut Springfield uses with the rear target sight. I chose the Harrison Extreme Service rear sight (model HD-002) as a replacement.

The Extreme Service sight is a one piece, CNC machined, low profile rear sight. It has 50 LPI (lines per inch) serrations cut into the rear to reduce the chance of glare affecting your sight picture. The blade has a squared off front face that you can use against the end of a table, counter, or whatever to operate your pistol one-handed (right there you know that this sight is more rugged than an adjustable sight - try doing that with an adjustable target sight and you may break part of it off in the process).

All of the edges and corners were treated to radius cuts during the machining process, so they are much more comfortable while handling, concealed carrying, and operating the pistol. If you want, you can even get night sight models with tritium inserts. They are currently available in either the 3-dot style or the single dot Heinie Straight-8 style.

Since this will not be primarily a carry pistol, I chose the standard sight without an insert and saved a little money. If I had changed the rear to tritium, I would have needed a tritium front sight to make proper use of the design.

My impressions of the sight are that is machined well, looks good, and adds different functionality while losing the original target sight's adjustability. I didn't need to make any kind of fitting adjustments to the sight during the installation process. It is a tight fit, as it should be, so you will want to use an installation tool designed for the purpose if you do it yourself. It has a wide notch just like the rear target sight, so you have essentially the same sight picture. The only complaint so far is that the matte black finish seems to possibly be a little bit thin. There were some wear marks on mine where it rubber against its plastic bag. Otherwise, I am very happy with this sight.

To install the Harrison Extreme Service rear sight, I first needed to remove the existing target sight from my Springfield without damaging anything. To accomplish that, I ordered a UNI-200L Universal Sight Mover from Brownell's.

Why buy a slide pusher instead of having a gunsmith install my sight? Well, as a woodworker and mechanically-inclined kind of guy, if I anticipate needing a tool more than once I usually go ahead and buy it. That saves money in the long run. First, you have the right tool for the job, which saves time and reduces the chance of fouling up your project. Second, you can use that tool over and over again for the one-time upfront cost of buying it the first time. Finally, you effectively pay for the tool after a few uses by not having to hire anyone.

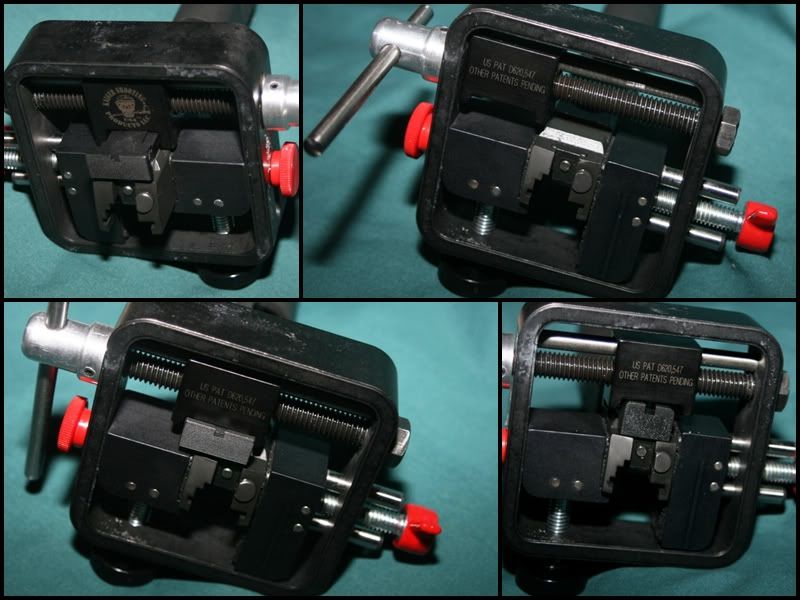

The UNI-2ooL is machined from heavy bar stock steel, and features coated jaw faces to reduce the chance of damaging either the pistol or the sights during the installation process. It is capable of removing and installing both front and rear dovetailed sights on the majority of semi-automatic pistol slides. It comes with an installation video on DVD, a vinyl fabric lined storage case, and an instruction sheet.

If a picture is worth 1,000 words, then the video is worth 10,000. If you watch the video, you probably won't even need the instruction sheet. Here are a few cautions I'd like to stress. Make sure the padding that should be stuck to the clamp jaws is in place so that you don't leave marks on your slide. You should also make sure there are no other objects, such as grit, on either the slide or clamp pads so it doesn't get ground into your slide. Also, when lining things up, make sure that neither the front nor rear set of pushers will contact any part of the slide itself. It may take some effort to begin to move the sight, but don't over do it if it doesn't seem to be working. You may be trying to move it in the wrong direction and you don't want to damage anything. If it's not working, stop and re-evaluate and maybe break out the written instructions.

The tool is very easy to use, you just need to lock your slide into place in line with the sight pushers and tighten down the two clamps. Then you just take your time to lineup the correct set of pushers connected to the top steel bar with the lowest point on the dovetail portion of your sight as you can without having it contact the slide at any point. Turn the handle to move the sight in the proper direction for removal (may vary by firearm manufacturer) until the sight is free of the slide.

Remove your slide at this point and start the new sight into the dovetail by hand. Return the sight to the Uni-200L and lock it into place. Turn the handle the opposite direction and push your new sight into the dovetail. When you have it centered, you're now good to go and your new sight is installed. The Harrison sight has a set screw in the top to help secure it in place, so tighten that down but don't over do it or you will possibly damage the slide underneath.

Okay, that's it. Installation should be about a 5 minute process if you're used to doing things like this. If not, take some extra time to make sure you don't damage anything.

In closing, I highly recommend both the Harrison Extreme Service rear sight (HD-002) and the Uni-200L Universal Sight Mover.

Harrison Extreme Service rear sight (HD-002)

Features: fits the LPA style cut (common on Springfield Armory and other 1911s with target sights)

CNC machined with 50 LPI serrations on the rear to reduce glare

squared off front face of the rear blade allows one-handed operation of the pistol

all edges and corners are machine radiused for handling, carrying, & operational comfort

rear notch dimensions 0.135" x 0.125" to allow adequate light for rapid sight picture

often regulates with OEM front sights that range from 0.170" to 0.200"

also available with tritium inserts

Finish: black

Price: $67.95 + shipping

Website: http://shop.harrisoncustom.com

UNI-200L Universal Sight Mover

Features: adjusts both front and rear dovetail sights on semi-automatic pistols

steel frame and inserts are machined from heavy bar stock

coated jaw faces reduce the chance of damage to pistol and/or sights

Price: about $160 + shipping

Website: http://www.brownells.com (see item 080-000-688)