A pause for the COZ

New member

Since acquiring some 30 cal AR's ( 300 Black out and 308 win)

My need for 30 cal lead slung paper thumpers has dramatically increased.

Used to be Pan Lubed then run through a LEE sizer was enough.

Then it was the LAM 2's turn.

I picked up a .310 die and punch for the Star.

Minor problem, Stars use the next bullet to Finnish pushing out the last bullet.

Not a issue with flat point bullets or larger rn like 45acp's

Spire point rifle bullets it messes up the gas check on the bullet in the die, and the nose of the following bullet.

Simplest fix is just to use a wood dowel or something similar to push out the bullet in the die.

But I found I was going just a bit too far and hitting the lube pump and gooping up the die and the rod.

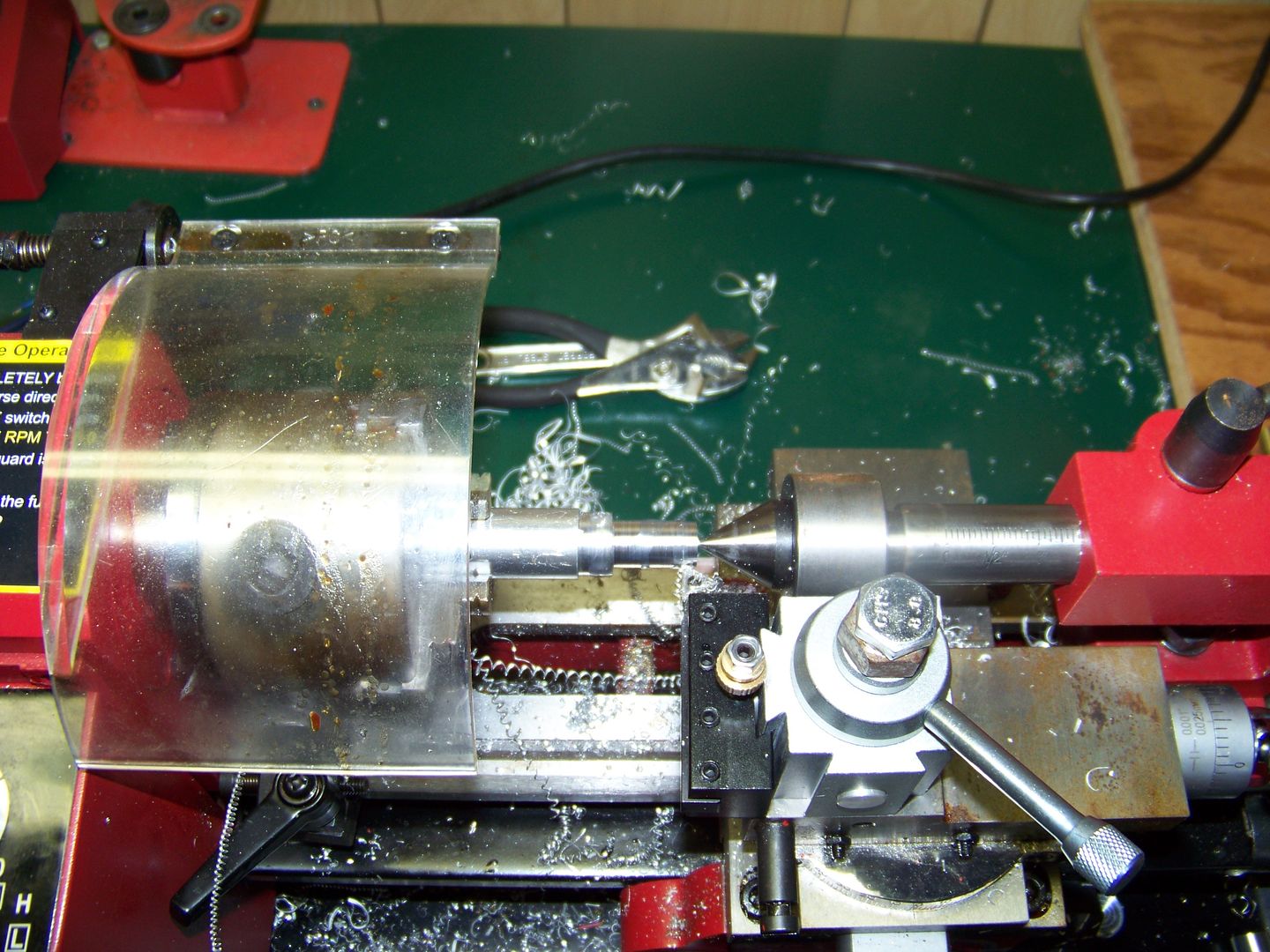

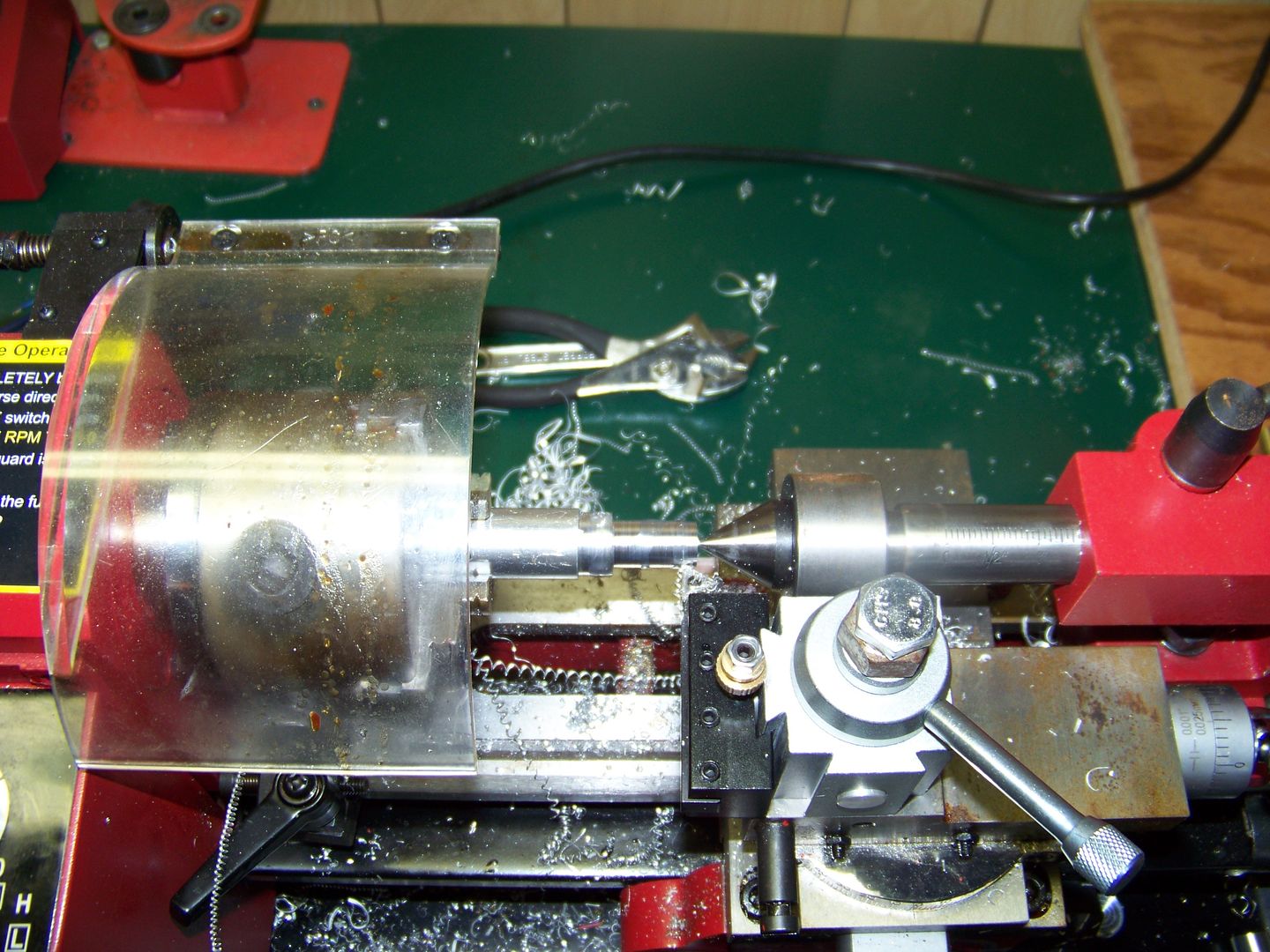

Since I have a lathe and need practice using it.

Might as well make a plug that pushes the bullet out and prevents me from hitting the lube pump.

Old image, but nothing better than when your Star gets on a groove with heat and air.

My need for 30 cal lead slung paper thumpers has dramatically increased.

Used to be Pan Lubed then run through a LEE sizer was enough.

Then it was the LAM 2's turn.

I picked up a .310 die and punch for the Star.

Minor problem, Stars use the next bullet to Finnish pushing out the last bullet.

Not a issue with flat point bullets or larger rn like 45acp's

Spire point rifle bullets it messes up the gas check on the bullet in the die, and the nose of the following bullet.

Simplest fix is just to use a wood dowel or something similar to push out the bullet in the die.

But I found I was going just a bit too far and hitting the lube pump and gooping up the die and the rod.

Since I have a lathe and need practice using it.

Might as well make a plug that pushes the bullet out and prevents me from hitting the lube pump.

Old image, but nothing better than when your Star gets on a groove with heat and air.