Part one started here:

http://thefiringline.com/forums/showthread.php?t=489006

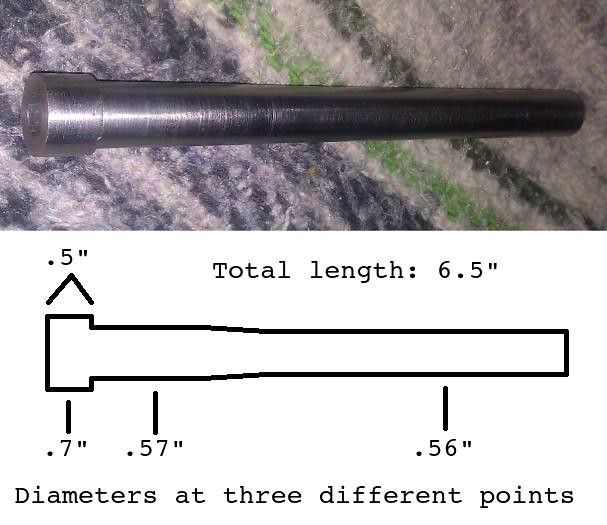

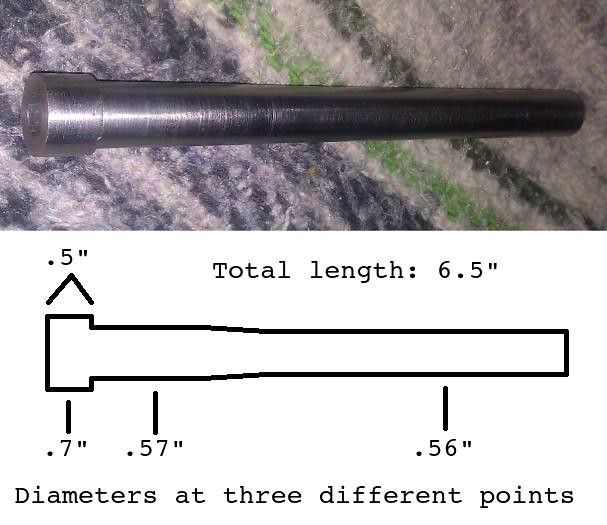

So browsing on Fleabay I came across a 6.5" piece of Douglas Premium barrel in 9mm (true .355) left over from a rifle project. For $15 I was all over it.

I can't photograph the inside very well but let's just say "Premium" doesn't even begin. Mirror-finish, clean-as-hell lands and grooves, just...awesome .

.

Now, there's a problem here. The fattest part is just a tad bigger than it needs to be for an 11/16th-24tpi thread, which is good. But at only .5" long, it's barely long enough to form barrel threads out of.

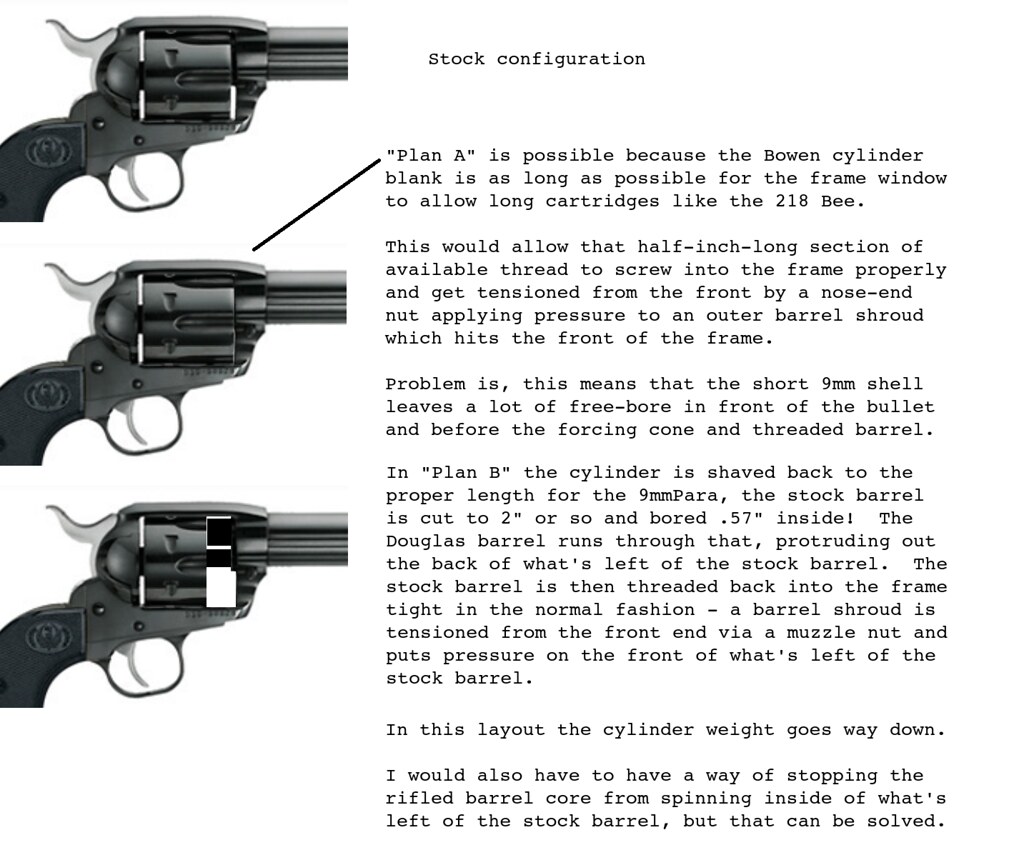

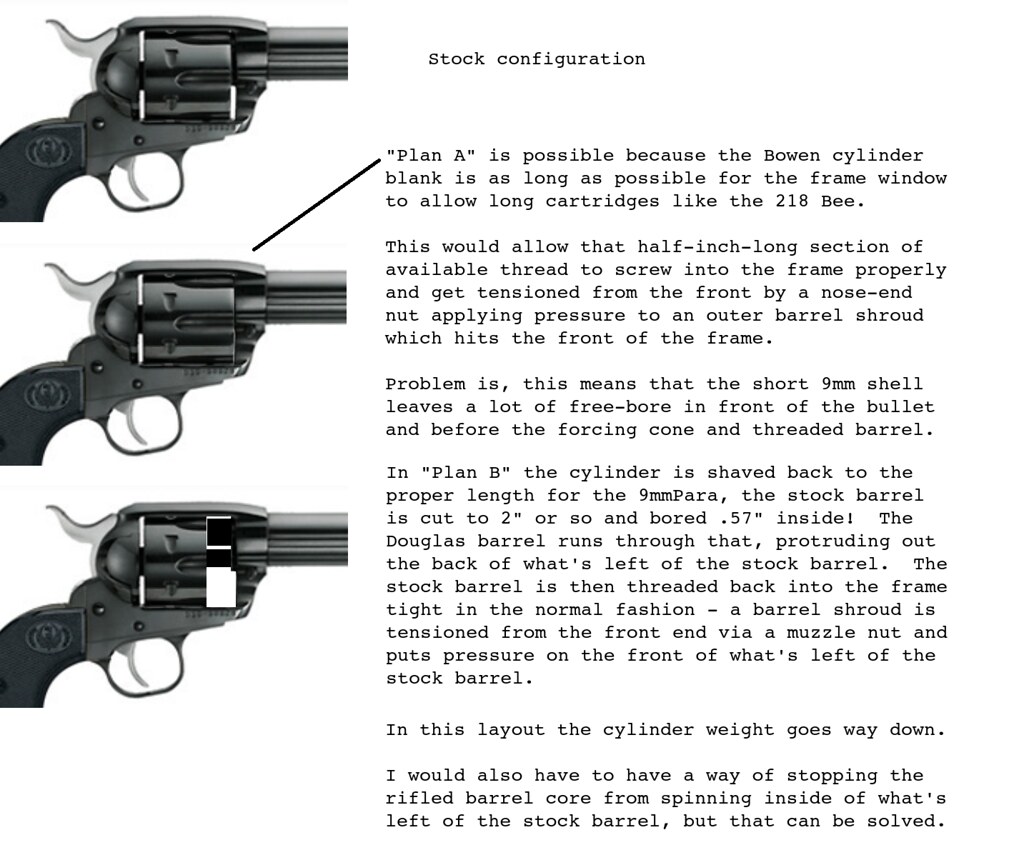

If the cylinder was of the stock length it wouldn't work out, because it would have to poke back about 3/16ths to meet the cylinder and the remaining thread length would be pretty marginal. Not a place I'd want to go.

BUT, I'm not going to be using a stock cylinder. I'll be using a Bowen blank which is over-long, to allow chambering in long shells like the 218 Bee. So it would meet up with the barrel fairly far forward.

In this setup, a threaded end-cap at the muzzle (unknown thread type, but that's a solvable problem) would push an outer barrel shroud tube back against the frame "Dan Wesson style", so the Douglas barrel on it's own doesn't need to get "screwed in tight" in the conventional fashion.

But I don't really like that. I'm calling it "Plan A". "Plan B" is even weirder:

I don't know if the lathe I have access to can re-bore the stock barrel (shortened to 1.5" or so?) to .57" smoothbore while keeping everything concentric. I should be able to find out Thursday when I can pick the brains of the two machinists I have access to. IF that can be done then yeah, we're good to go: put the Douglas barrel inside that modified stock barrel, screw the stock barrel in tight, tension the inner barrel via a muzzle-end nut pushing a barrel shroud against the front of what's left of the stock barrel.

That remaining stub of a stock barrel can be turned on the lathe to have a slightly "pointed" forward face, so that the shroud auto-centers on it as everything is cranked down from the muzzle end.

I'll also need a way to make sure the inner Douglas barrel doesn't spin against the outer remaining stub of stock barrel. That can be solved a few ways, perhaps with a small woodruff key in a machined-in channel.

The forward muzzle nut will also double as a gas-tap chamber and a front sight base.

http://thefiringline.com/forums/showthread.php?t=489006

So browsing on Fleabay I came across a 6.5" piece of Douglas Premium barrel in 9mm (true .355) left over from a rifle project. For $15 I was all over it.

I can't photograph the inside very well but let's just say "Premium" doesn't even begin. Mirror-finish, clean-as-hell lands and grooves, just...awesome

Now, there's a problem here. The fattest part is just a tad bigger than it needs to be for an 11/16th-24tpi thread, which is good. But at only .5" long, it's barely long enough to form barrel threads out of.

If the cylinder was of the stock length it wouldn't work out, because it would have to poke back about 3/16ths to meet the cylinder and the remaining thread length would be pretty marginal. Not a place I'd want to go.

BUT, I'm not going to be using a stock cylinder. I'll be using a Bowen blank which is over-long, to allow chambering in long shells like the 218 Bee. So it would meet up with the barrel fairly far forward.

In this setup, a threaded end-cap at the muzzle (unknown thread type, but that's a solvable problem) would push an outer barrel shroud tube back against the frame "Dan Wesson style", so the Douglas barrel on it's own doesn't need to get "screwed in tight" in the conventional fashion.

But I don't really like that. I'm calling it "Plan A". "Plan B" is even weirder:

I don't know if the lathe I have access to can re-bore the stock barrel (shortened to 1.5" or so?) to .57" smoothbore while keeping everything concentric. I should be able to find out Thursday when I can pick the brains of the two machinists I have access to. IF that can be done then yeah, we're good to go: put the Douglas barrel inside that modified stock barrel, screw the stock barrel in tight, tension the inner barrel via a muzzle-end nut pushing a barrel shroud against the front of what's left of the stock barrel.

That remaining stub of a stock barrel can be turned on the lathe to have a slightly "pointed" forward face, so that the shroud auto-centers on it as everything is cranked down from the muzzle end.

I'll also need a way to make sure the inner Douglas barrel doesn't spin against the outer remaining stub of stock barrel. That can be solved a few ways, perhaps with a small woodruff key in a machined-in channel.

The forward muzzle nut will also double as a gas-tap chamber and a front sight base.