You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Forcing cone angle

- Thread starter 1100 tac

- Start date

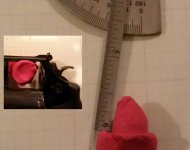

I have a 1907 vintage colt 32 S&W Long that blew out the forcing cone with wimp loads. So I welded it up and cut a new one at 11 degrees and thicker. I got 1413 fps over the chrono with an 85 gr bullet.

Attachments

1100 Tac,

11° is a pretty standard forcing cone angle. ONe new revolver I bought that had something different was my Dan Wesson 15-2, which came with 5° throat angles on the two barrels I have for it. The S&W's I have are all 11° if they are factory.

Changing to 5° used to be a standard revolver smith's accurizing technique for shooting lead bullets. I believe, however, that cutting of the shallower angle was often done with a piloted pull-through reamer and the final forcing cone cleaned up with laps, in situ. That would allow the longer taper to get at least into if not past the barrel constrictions commonly found in that part of the gun, which might well have been the main source of the beneficial effect.

11° is a pretty standard forcing cone angle. ONe new revolver I bought that had something different was my Dan Wesson 15-2, which came with 5° throat angles on the two barrels I have for it. The S&W's I have are all 11° if they are factory.

Changing to 5° used to be a standard revolver smith's accurizing technique for shooting lead bullets. I believe, however, that cutting of the shallower angle was often done with a piloted pull-through reamer and the final forcing cone cleaned up with laps, in situ. That would allow the longer taper to get at least into if not past the barrel constrictions commonly found in that part of the gun, which might well have been the main source of the beneficial effect.

My experience seems to be different. My understanding is that S&W uses an 8 degree cutter to cut the forcing cone. Kind of a compromise between what works best for jacketed (5 degrees) and cast lead (11 degrees).

I have recut a few S&W's I use mostly for lead. I use an 11 degree cutter and it has certainly changed the angle that it came from the factory with.

If you recast your barrel using Cerrosafe you will get a much more accurate mold to measure the angle with.

I have recut a few S&W's I use mostly for lead. I use an 11 degree cutter and it has certainly changed the angle that it came from the factory with.

If you recast your barrel using Cerrosafe you will get a much more accurate mold to measure the angle with.

Re: cerrosafe

I have cerrosafe and know how to use it, the problem is pouring just the right amount in order to get the cast out, and have enough length to accurately measure the angle, plus if there is a bore restriction at the bbl threads it would have to be pounded out, I don't want to do that...

The goal here is to make a lap to polish up what I have a little. I can make different angled laps until I match it, but I wanted to save time and materiel.

I never dreamed that it would be this hard to find out the spec.

I have posted this on four forums and the #'s have come back all over the place, "I think" and "probably" , So, I don't think anyone out there in internet land really KNOWS...

Will be calling S&W today to see if THEY know...

Thanks for the responses guys, I will let you know what Smith says.

I have cerrosafe and know how to use it, the problem is pouring just the right amount in order to get the cast out, and have enough length to accurately measure the angle, plus if there is a bore restriction at the bbl threads it would have to be pounded out, I don't want to do that...

The goal here is to make a lap to polish up what I have a little. I can make different angled laps until I match it, but I wanted to save time and materiel.

I never dreamed that it would be this hard to find out the spec.

I have posted this on four forums and the #'s have come back all over the place, "I think" and "probably" , So, I don't think anyone out there in internet land really KNOWS...

Will be calling S&W today to see if THEY know...

Thanks for the responses guys, I will let you know what Smith says.

I have posted this on four forums and the #'s have come back all over the place, "I think" and "probably" , So, I don't think anyone out there in internet land really KNOWS...

http://www.saami.org/PubResources/CC_Drawings/Pistol/44 Remington Magnum.pdf

F. Guffey

Jepp2,

It may be the age of my Smiths. Nothing recent. It can fool you, though. I have had the experience with a .357 Magnum barrel (one of my DW's) of chucking it in the lathe and finding a dial indicator showing a 3° angle over the center to rifling portion of the forcing cone. That, however, was created by erosion. The newer barrel's less worn forcing cone is flatter and 5°.

If Cerrosafe isn't convenient, you can always apply mold release and put some quick set epoxy putty in for an impression. Exact dimensions don't matter, as the angle will be the same even if the diameters overall all are a tiny bit smaller.

It may be the age of my Smiths. Nothing recent. It can fool you, though. I have had the experience with a .357 Magnum barrel (one of my DW's) of chucking it in the lathe and finding a dial indicator showing a 3° angle over the center to rifling portion of the forcing cone. That, however, was created by erosion. The newer barrel's less worn forcing cone is flatter and 5°.

If Cerrosafe isn't convenient, you can always apply mold release and put some quick set epoxy putty in for an impression. Exact dimensions don't matter, as the angle will be the same even if the diameters overall all are a tiny bit smaller.

Last edited:

http://www.saami.org/PubResources/CC...n Magnum.pdf Doesn't show forcing cone angle. The eleven degree, six minute dimension is for the chamber. Note to the right side of the drawing the noted "Barrel Face" and "Cylinder Face", but no angle called out...

I have posted this on four forums and the #'s have come back all over the place, "I think" and "probably" , So, I don't think anyone out there in internet land really KNOWS...

You have covered the Internet reloading forums like the wind and found:

don't think anyone out there in internet land really KNOWS

Why? I am not even curious.

But if I was and I wanted to know I would seat a bullet into a case without powder, I would then chamber the round and pull the trigger. If I was curious about the most powerful primers I would use different primers to determine how far each drove the bullet in the forcing cone.

F. Guffey

FGuffy: If you are not curious, I won't twist your arm to read anything I post

don't think anyone out there in internet land really KNOWS

Again, seat seat a bullet into a primed case without powder, chamber the round and pull the trigger. Use a jacketed bullet or a lead bullet. And then drive the bullet back into the cylinder. Check the impring on the bullet.

Or as you say:

I have cerrosafe and know how to use it, the problem is pouring just the right amount in order to get the cast out, and have enough length to accurately measure the angle, plus if there is a bore restriction at the bbl threads it would have to be pounded out, I don't want to do that

You know how to use cerrosafe.

F. Guffey