Playboypenguin

Moderator

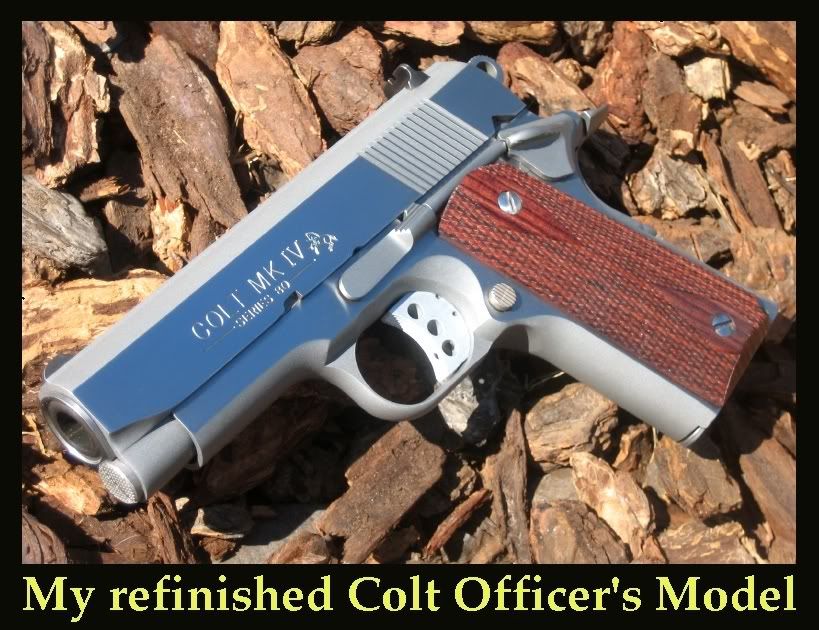

I have been using a glass bead medium since I first started pressure blasting my firearms. The bead is great for giving that "pearlescent" finish to the metal but it just did not leave a flat enough finish to give the proper contrast on a two tone gun like a 1911.

I tried a couple different mediums this weekend and found one I think is perfect for that "flatter" matte finish I was seeking.

I ended up going with #100 Garnet. I think it gives the perfect contrast and roughness while still being very smooth and refined looking. It is a lot cheaper than the iron oxide and others I tried also.

Here is a pic. You will notice I got a little bleed on on the body of the slide's side. I will buff that right out in a short while.

I tried a couple different mediums this weekend and found one I think is perfect for that "flatter" matte finish I was seeking.

I ended up going with #100 Garnet. I think it gives the perfect contrast and roughness while still being very smooth and refined looking. It is a lot cheaper than the iron oxide and others I tried also.

Here is a pic. You will notice I got a little bleed on on the body of the slide's side. I will buff that right out in a short while.