So I've still got the 10mm Auto Ord kit that I don't want to shoot on my 1911. I talked a while ago about doing a build with it, basically just getting a frame to build up and then slap this sucker on board for a dedicated 10mm. Got the frame and have been moving slowly on picking up other parts. Finally got around to taking a look at everything last night and indeed, it seems the slide will need a bit of work to fit to the frame. Whether the slide is too narrow or the frame is too loose, I'm not sure, but I figured I would bring it up here to see how people thought I should proceed. I've done a little bit of searching into how to fit the two, but there actually aren't a bunch of threads on the topic as I expected. So I guess I'd ask for input and the methods best for a beginner.

What sounds easiest, that I've read so far, is basically rubbing it down with some lapping compound and then pounding it back and forth with a hammer until it's doable by hand, then gradually improving it with other substances until it will slide under its own weight. If anyone can recommend specific products or techniques for this method, or has a better method for my purposes, I'd appreciate it.

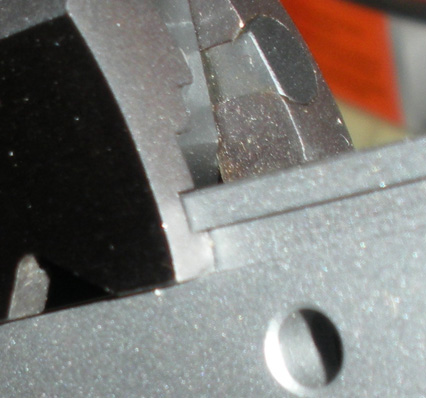

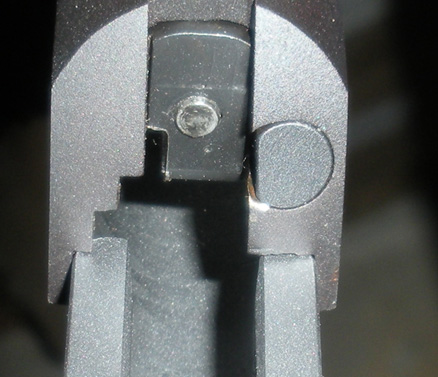

Below are some pictures of what I'm working with. No particular method to selecting the angles other than they were the ones that were in better focus

What sounds easiest, that I've read so far, is basically rubbing it down with some lapping compound and then pounding it back and forth with a hammer until it's doable by hand, then gradually improving it with other substances until it will slide under its own weight. If anyone can recommend specific products or techniques for this method, or has a better method for my purposes, I'd appreciate it.

Below are some pictures of what I'm working with. No particular method to selecting the angles other than they were the ones that were in better focus