nvdwarrior

Inactive

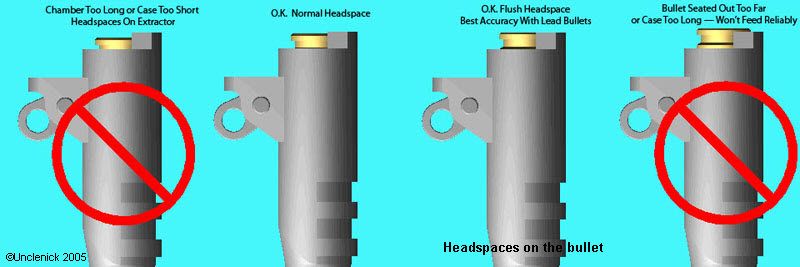

I am having a hard time finding a measured OAL for these new Rocky Mountain (RMR) .45 Cal (.482) 185grain LSWC bullets I purchased. It appears that folks set these bullets by visual depth of the bullet collar being just above the cartridge rim. It has been described as a fingernail or matchbook sized lip. My question is, these bullets appear to be the longer type of a LSWC. It looks like an OAL measurement would be more appropriate than the visual method. I am not too worried about overpressure using a very light load of Bullseye (4.6g). Its for plinking at no more than 50 feet. So has anyone developed an average OAL for this bullet or does this learned group agree that visual seating coupled with functioning will be OK. thanks in advance for any advice. I have been reloading only round nose plated .45 230g and 200g. up to this point.