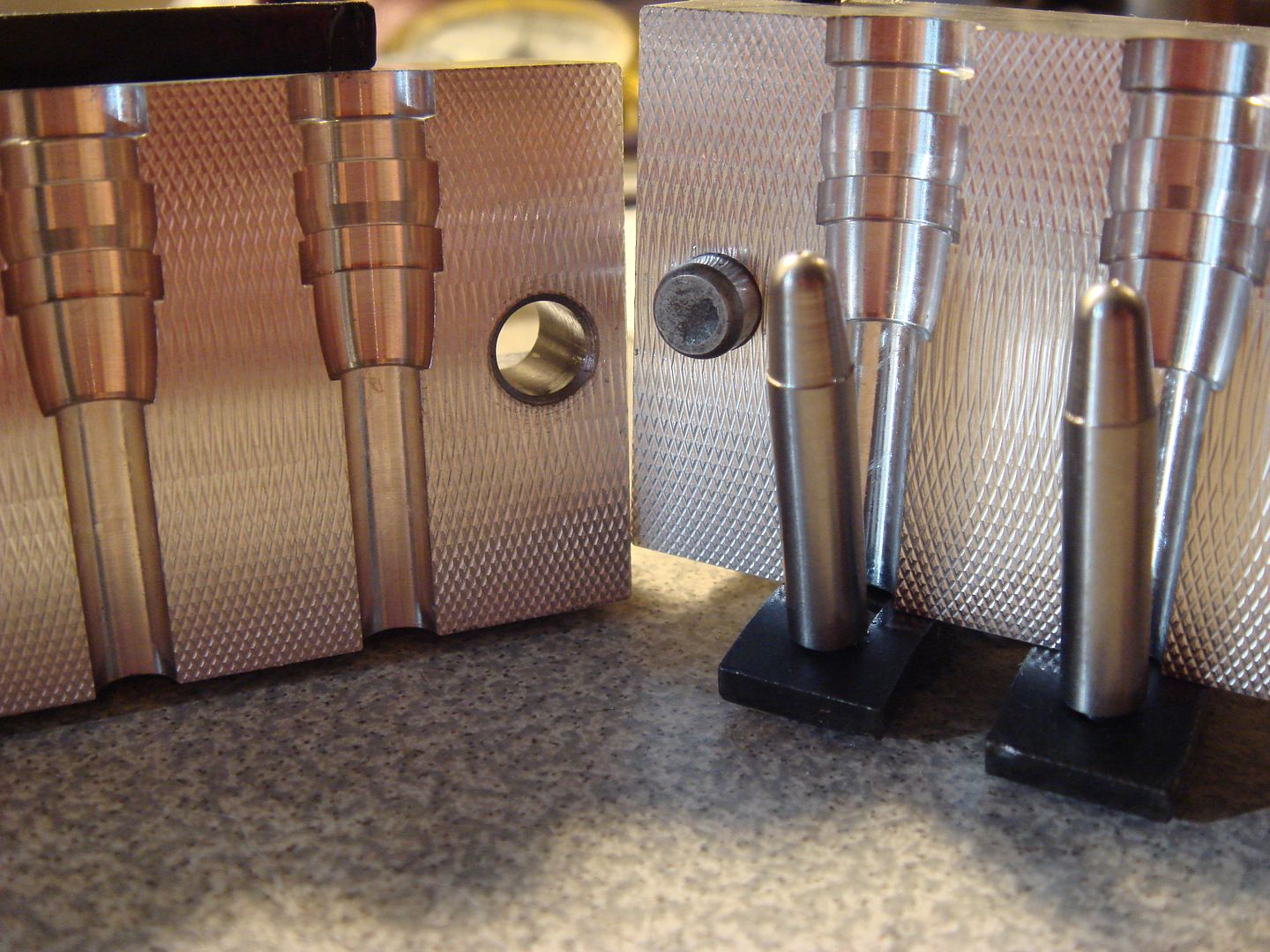

This is with a 2 cav NOE 358429 RG2 hollow point mold. I'll post a pic below if you didn't see the other thread.

Well... I think they turned out really nice.

It started off slowly. I think I didn't wait for the pot to get up to top temp before I started, because the mold was on the hot plate for 20 mins, so I know it was hot. I didn't do any mold prep other than take it out of the box, screw it to the handles, squirt some Dawn on a toothbrush and hold the mold under the sink by the handles and scrub the cavities out for a minute. Then I put it right on the hot plate to dry/heat up. Right before I started casting, I applied bullplate lube (comes with a NOE mold) to the bottom of the sprue plate, the sprue plate bolt, the alignment pins and the tips of the HP pins (using a Qtip). So it took about 20-25 pours to get everything hot enough for the wrinkles to go away, and then it was pretty smooth sailing after that. I think I made friends with it, once it was hot. I was going pour a whole pot, but my ol' leg reminded me that it wasn't 100% healed up yet, so I only poured 10#. I was using a Lee 20# pot and a Lyman ladle.

I didn't do any mold prep other than take it out of the box, screw it to the handles, squirt some Dawn on a toothbrush and hold the mold under the sink by the handles and scrub the cavities out for a minute. Then I put it right on the hot plate to dry/heat up. Right before I started casting, I applied bullplate lube (comes with a NOE mold) to the bottom of the sprue plate, the sprue plate bolt, the alignment pins and the tips of the HP pins (using a Qtip). So it took about 20-25 pours to get everything hot enough for the wrinkles to go away, and then it was pretty smooth sailing after that. I think I made friends with it, once it was hot. I was going pour a whole pot, but my ol' leg reminded me that it wasn't 100% healed up yet, so I only poured 10#. I was using a Lee 20# pot and a Lyman ladle.

My friend who gave me the pot had said that the dial was really close on temp and so when I got to the perfect spot where the b̶o̶o̶l̶i̶ bullets were just falling out of the mold, I opened my box containing my trusty new Rotometals thermometer and it said I was at 820 degrees. Lots of folks will say that is too hot, but I always put the pot on 8-1/4 on the dial to start with, and ease it down to about 7 as the lead level falls, so I guess I always pour at 820 or thereabouts. I was using my usual isotope alloy of 95/2.5/2.5 for these.

And here are the results from my kinda short pouring session this morning.

Well... I think they turned out really nice.

It started off slowly. I think I didn't wait for the pot to get up to top temp before I started, because the mold was on the hot plate for 20 mins, so I know it was hot.

My friend who gave me the pot had said that the dial was really close on temp and so when I got to the perfect spot where the b̶o̶o̶l̶i̶ bullets were just falling out of the mold, I opened my box containing my trusty new Rotometals thermometer and it said I was at 820 degrees. Lots of folks will say that is too hot, but I always put the pot on 8-1/4 on the dial to start with, and ease it down to about 7 as the lead level falls, so I guess I always pour at 820 or thereabouts. I was using my usual isotope alloy of 95/2.5/2.5 for these.

And here are the results from my kinda short pouring session this morning.