Today was my first attempt at powder coating bullets. It was a success...well, not so much.

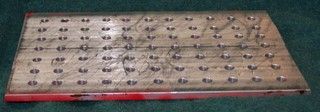

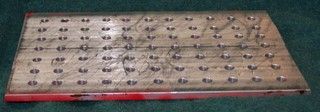

I will start at the beginning. My first attempt is for my .30 M1 Carbine and an RCBS gas check design. I got a 3/16 thick plate of aluminum, spaced holes every 3/4 inch. Drilled 1/8 pilot holes and followed-up with an "L" size drill bit, drilling through.

The fixture will hold 70 bullets, placed in the holes base-first. The gas check fit in the hole, the driving band stops them from dropping through.

I covered the fixture with non-stick aluminum foil, but used "Great Value" which is a Walmart store brand. I pushed the base of the bullets through the aluminum foil into the fixture.

I set-up my new Harbor Freight powder coating machine and dusted the bullets. I put the fixture with the powder coated bullets into my new toaster oven and baked them at 400 degrees for twenty minutes. As they were baking, I noticed that I had not gotten full coverage near the bases of the bullets, so then they came out of the oven, I re-powder coated them and baked them again...I got complete coverage that time, but when I cooled them and tried to remove them from the aluminum foil, non-stick was not non-stick. Removing them resulted in a "flash" of hardened powder coating left on the bullets and aluminum foil stuck in the same area also. I don't know if it was an aluminum foil failure or if it was the two coats, two bakes that caused the problem.

I got the "pretty" bullets I was looking for, but with the time it will take to remove the flash and bits of aluminum foil from the bullets, it does not seem worth the effort. I am not finished experimenting though...I will tumble coat some plain base .45 ACP's (will set on parchment paper for those), and see if that goes better.

I will start at the beginning. My first attempt is for my .30 M1 Carbine and an RCBS gas check design. I got a 3/16 thick plate of aluminum, spaced holes every 3/4 inch. Drilled 1/8 pilot holes and followed-up with an "L" size drill bit, drilling through.

The fixture will hold 70 bullets, placed in the holes base-first. The gas check fit in the hole, the driving band stops them from dropping through.

I covered the fixture with non-stick aluminum foil, but used "Great Value" which is a Walmart store brand. I pushed the base of the bullets through the aluminum foil into the fixture.

I set-up my new Harbor Freight powder coating machine and dusted the bullets. I put the fixture with the powder coated bullets into my new toaster oven and baked them at 400 degrees for twenty minutes. As they were baking, I noticed that I had not gotten full coverage near the bases of the bullets, so then they came out of the oven, I re-powder coated them and baked them again...I got complete coverage that time, but when I cooled them and tried to remove them from the aluminum foil, non-stick was not non-stick. Removing them resulted in a "flash" of hardened powder coating left on the bullets and aluminum foil stuck in the same area also. I don't know if it was an aluminum foil failure or if it was the two coats, two bakes that caused the problem.

I got the "pretty" bullets I was looking for, but with the time it will take to remove the flash and bits of aluminum foil from the bullets, it does not seem worth the effort. I am not finished experimenting though...I will tumble coat some plain base .45 ACP's (will set on parchment paper for those), and see if that goes better.