Well I bought this gun a few months ago but due to traveling for work, I haven't had a chance to shoot it...so what do you do with money and no time...BUY stuff! So I put a geiselle (sp?) two stage in it, accurizing wedge, hogue grip,and prs stock all on it before even shooting it. Lol I also bought 300rds of federal gold match ($19.95 per box!).

I have been searching and searching, trying to figure out if the break-in process was hog wash or not. I came to my own conclusion that in a custom, hand lapped barrel, the first shot is the probably the best shot...a factory barrel may require some smoothing....but I was still a skeptic and I believe more harm can be done to a barrel by improper cleaning than break-in or no break-in.

I decided I wasn't putting any rod down this barrel until I got a Lucas bore guide so after seeing the idea on the net, I made my own patchworm. .281" hole seems to fit nicely with the thickness patches that I am using.

I don't know how many rounds DPMS test fires but the last few inches that I could see of the barrel had excessive amounts of copper fouling. It took me about 45mins with butches bore shine to get it all out.

This past saturday I got the chance to shoot it, I had no scope or bipod so to wally world I went...I'll replace these items later. Don't knock my $70 Centerpoint scope, I'm going to see how long it lasts lol.

Anywho, it was hot, real hot here, about 95F in the shade. We set up at 100yds with a huge piece of cardboard and a target in the middle of it.

The only other centerfire I have ever shot before is a hand-me-down .270 bolt action, so I was curious about a gas operated 308.

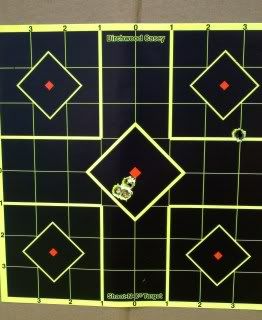

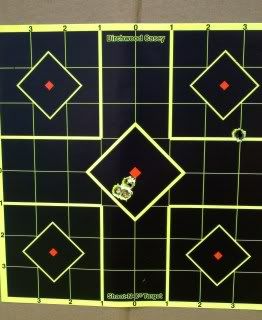

First shot was (i guessed through scope) 15in low, 7 in left. I took a peek at the barrel, no copper...so I made adjustments then fired off the second round, 3in right, 1in high as you can see. Again, no copper so I continued without cleaning.

Again I made adjustments and decided to fire off three rounds to get a group.

If this barrel "breaks-in" and gets anymore accurate, I don't know if I am going to be able to stand it lol.

I LOVE this gun!!! and I have to mention that I also LOVE this gun!!! Such a sweet shooter.

I let my brother, his fiance and my dad shoot a few rounds thru it. I then shot another 3 shot group with two rounds almost in the same hole and one about an inch high and to the right....I then discovered a loose scope ring so decided to call it quits.

Sorry for the book, thanks for reading/looking. FYI I was so excited about the picture that I didn't notice the upside down box of ammo for the picture...lol...ahh well.

One question though, anyone recommend a good repair/upgrade kit for the internals? Cam pin, piston rings, etc? Prior to shooting I pulled it all apart and clean then lubed with break free and it cycled flawlessly but I just want to make sure I have extra parts next time I make it out to the farm so I don't have to end my day short.

I have been searching and searching, trying to figure out if the break-in process was hog wash or not. I came to my own conclusion that in a custom, hand lapped barrel, the first shot is the probably the best shot...a factory barrel may require some smoothing....but I was still a skeptic and I believe more harm can be done to a barrel by improper cleaning than break-in or no break-in.

I decided I wasn't putting any rod down this barrel until I got a Lucas bore guide so after seeing the idea on the net, I made my own patchworm. .281" hole seems to fit nicely with the thickness patches that I am using.

I don't know how many rounds DPMS test fires but the last few inches that I could see of the barrel had excessive amounts of copper fouling. It took me about 45mins with butches bore shine to get it all out.

This past saturday I got the chance to shoot it, I had no scope or bipod so to wally world I went...I'll replace these items later. Don't knock my $70 Centerpoint scope, I'm going to see how long it lasts lol.

Anywho, it was hot, real hot here, about 95F in the shade. We set up at 100yds with a huge piece of cardboard and a target in the middle of it.

The only other centerfire I have ever shot before is a hand-me-down .270 bolt action, so I was curious about a gas operated 308.

First shot was (i guessed through scope) 15in low, 7 in left. I took a peek at the barrel, no copper...so I made adjustments then fired off the second round, 3in right, 1in high as you can see. Again, no copper so I continued without cleaning.

Again I made adjustments and decided to fire off three rounds to get a group.

If this barrel "breaks-in" and gets anymore accurate, I don't know if I am going to be able to stand it lol.

I LOVE this gun!!! and I have to mention that I also LOVE this gun!!! Such a sweet shooter.

I let my brother, his fiance and my dad shoot a few rounds thru it. I then shot another 3 shot group with two rounds almost in the same hole and one about an inch high and to the right....I then discovered a loose scope ring so decided to call it quits.

Sorry for the book, thanks for reading/looking. FYI I was so excited about the picture that I didn't notice the upside down box of ammo for the picture...lol...ahh well.

One question though, anyone recommend a good repair/upgrade kit for the internals? Cam pin, piston rings, etc? Prior to shooting I pulled it all apart and clean then lubed with break free and it cycled flawlessly but I just want to make sure I have extra parts next time I make it out to the farm so I don't have to end my day short.