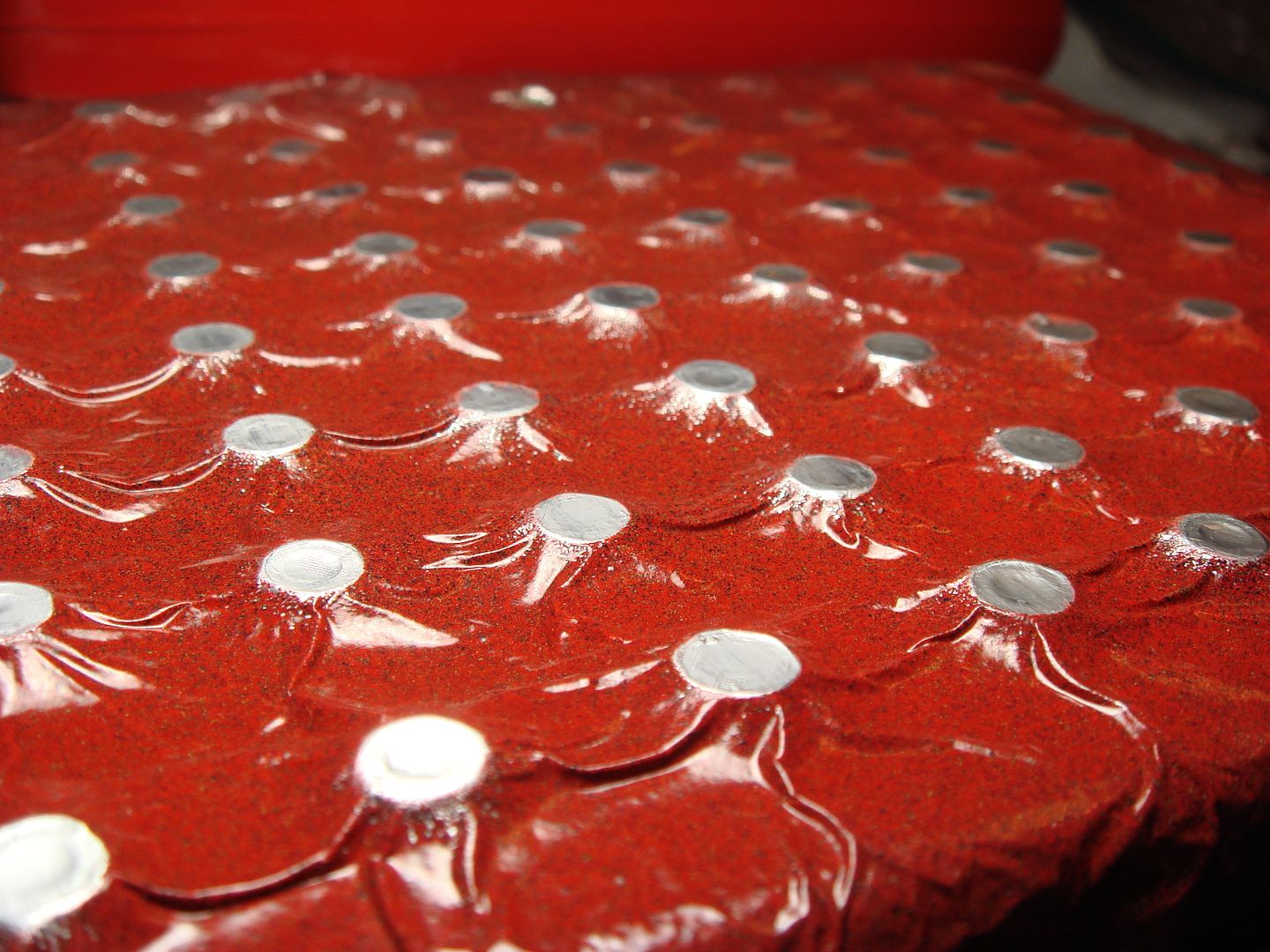

Dont use cheap tin foil pans for baking.. bullets melt

Dont use "non stick" foil when baking.. foil sticks to bottom of bullets

Please post your Do's and Dont's.

Mainly so i can read them and not keep asking questions like a damn retread. 0.o

Any one know how to get the pc off the baking pan. Ugggg

Dont use "non stick" foil when baking.. foil sticks to bottom of bullets

Please post your Do's and Dont's.

Mainly so i can read them and not keep asking questions like a damn retread. 0.o

Any one know how to get the pc off the baking pan. Ugggg