DirtyHarold

New member

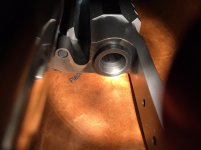

I had to send a revolver in to the manufacturer because the timing was off. They replaced some timing components as well as the cylinder, but they also recut the forcing cone which I found surprising. Is this standard practice for cylinder replacements? Why else might they have done this?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk